Copper-based catalyst, preparation method thereof and application of copper-based catalyst to furfural hydrogenation catalysis

A copper-based catalyst and catalyst technology, applied in the field of catalytic chemistry, can solve problems that need to be further improved, and achieve the effects of reproducible use of equipment corrosion, simple preparation process, and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

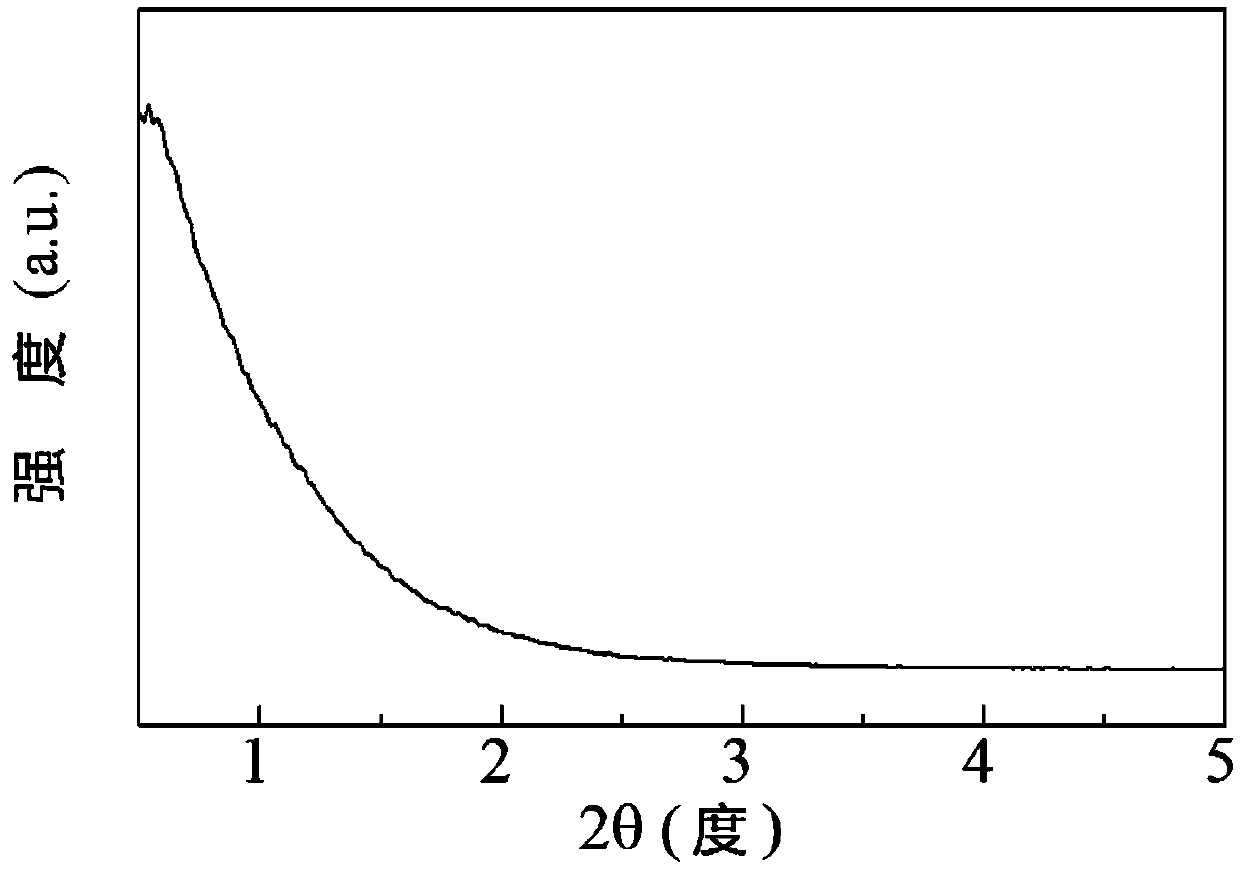

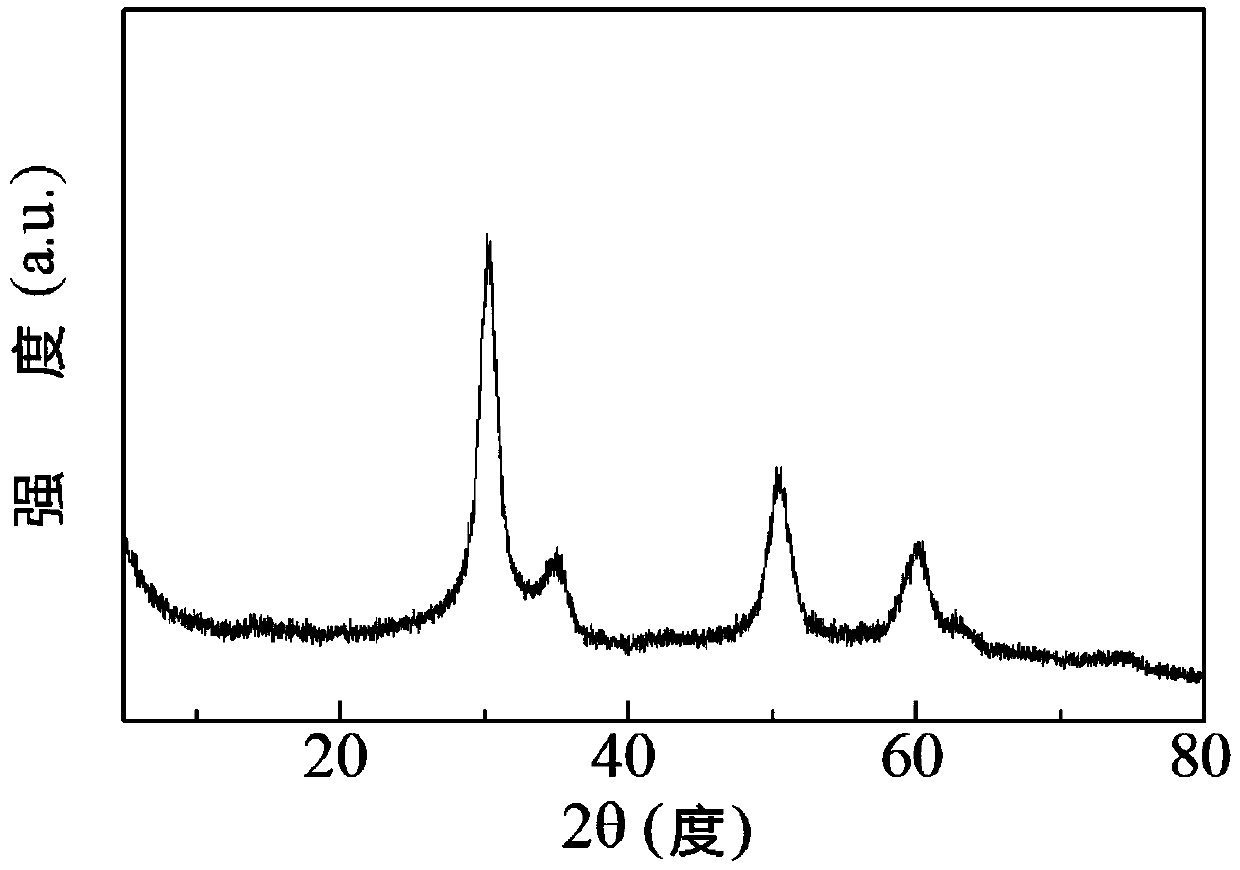

[0029] The preparation method of the present invention can realize the carrier ZrO by controlling the molar ratio of the solution, reaction temperature, pressure, time and other factors. 2 -M Modulation of pore diameter and pore volume. According to the requirements of the catalytic performance of furfural hydrogenation to furfuryl alcohol, the carrier ZrO 2 -M pore structure size can be adjusted within the following range: BET specific surface: 100 ~ 300m 2 g -1 ;Pore diameter: 2.5~6nm; Pore volume: 0.1~0.3cm 3 g -1 .

[0030] Compared with the prior art, the present invention has simple operation, mild preparation conditions and good controllability; the prepared product has large specific surface area and high activity; the prepared mesoporous zirconia exhibits higher activity in furfural hydrogenation reaction and selective. Under optimized conditions, complete conversion of furfural can be achieved, and the total yield of furfuryl alcohol can reach over 99%.

Embodiment 1

[0033] Under the constant temperature condition of 40℃, 2.0g P123(EO 20 PO 20 EO 20 ) was dissolved in 30g of absolute ethanol, and stirred vigorously for 3 hours to obtain solution A; another 30g of absolute ethanol was weighed, and 1.0g of acetylacetone (acac) and 6g of zirconium n-propoxide were added, which was recorded as solution B; Mix solutions A and B, add 1.5 g of deionized water, and continue stirring for 3 hours to form a milky white gel. The gel was transferred to a polytetrafluoroethylene-lined autoclave, crystallized at 45 °C for 48 h, and then treated with 0.5 mol L -1The NaOH solution was refluxed for 24 hours, cooled, filtered, washed, dried overnight at 100°C, and the powder was roasted in a muffle furnace at 550°C, and the obtained product carrier was designated as ZrO 2 -M.

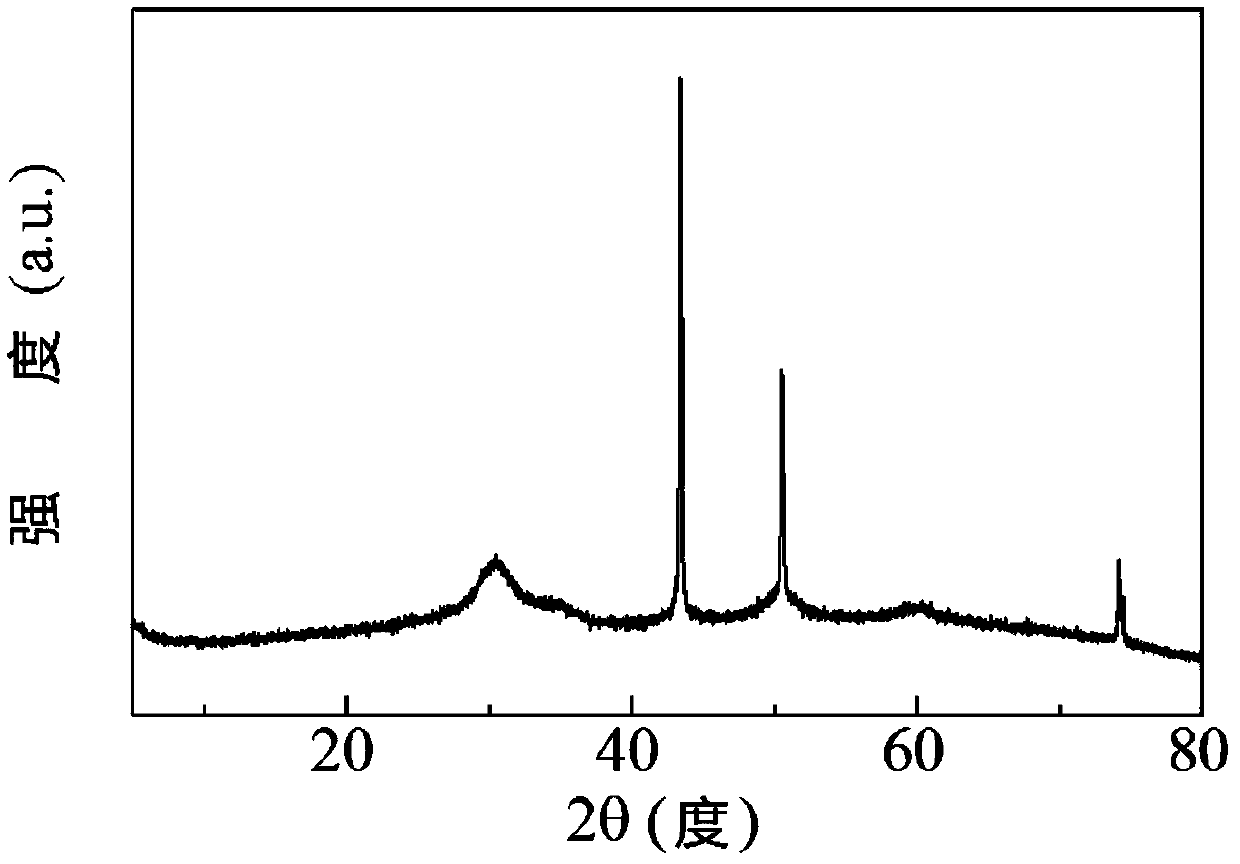

[0034] Cu / ZrO 2 - Preparation of M catalyst: make copper nitrate into an aqueous solution with a mass concentration of 50 wt%. Then, the solution was impregnated with the carrie...

Embodiment 2

[0038] Under the constant temperature condition of 50℃, 1.0g P123(EO 20 PO 20 EO 20 ) was dissolved in 30g of absolute ethanol, and stirred vigorously for 4 hours to obtain solution A; another 30g of absolute ethanol was weighed, and 0.5g of acetylacetone (acac) and 8g of zirconium n-propoxide were added, which was recorded as solution B; Mix solutions A and B, add 2.0 g of deionized water, and continue stirring for 3 hours to form a milky white gel. The gel was transferred to a polytetrafluoroethylene-lined autoclave, crystallized at 50 °C for 48 h, and then treated with 0.5 mol L -1 The NaOH solution was refluxed for 24 hours, cooled, filtered, washed, dried overnight at 100°C, and the powder was roasted in a muffle furnace at 550°C, and the obtained product carrier was designated as ZrO 2 -M.

[0039] Cu / ZrO 2 - Preparation of M catalyst: make copper nitrate into an aqueous solution with a mass concentration of 25 wt%. Then, the solution was impregnated with the carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com