A kind of porous metal oxide particle and preparation method thereof

A technology of oxide particles and porous metals, applied in chemical instruments and methods, oxygen/ozone/oxides/hydroxides, non-metallic elements, etc., can solve the problem of difficult removal of templates, high production costs, and low production efficiency and other issues, to achieve good market prospects, low cost, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

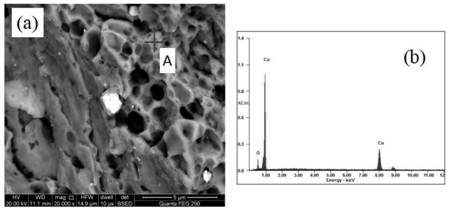

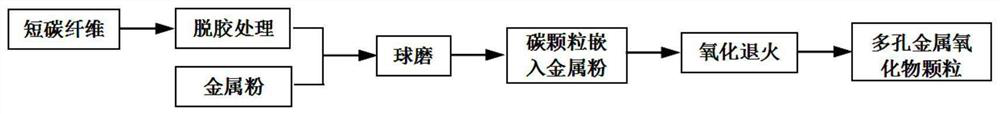

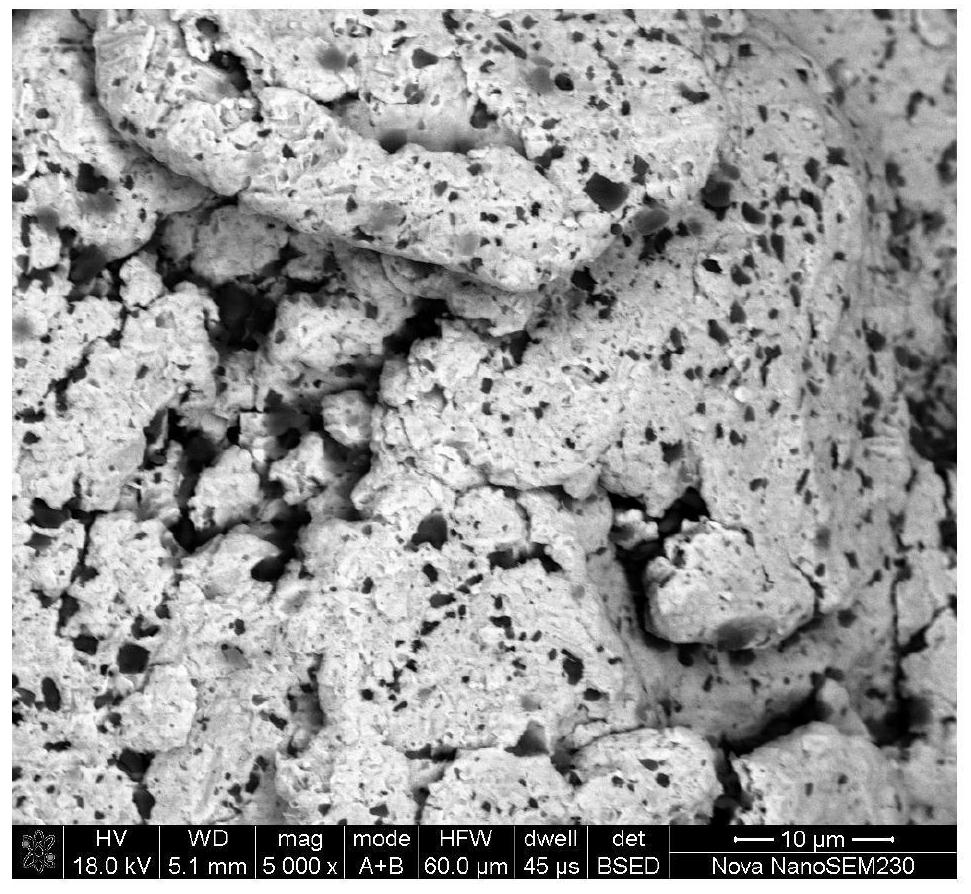

[0054] In this example 1, commercially available short carbon fibers that have been degummed at 700°C for 60 minutes and electrolytic copper powder with a particle size of 120 μm are used as ball milling raw materials. The volume percentage of short carbon fibers is 10%, and the volume percentage of electrolytic copper powder is 90%. The diameter is 6 μm, and the length is 2 mm. The two are added to a ball mill for high-energy ball milling at a speed of 250 r / min, a ball milling time of 6 hours, and a ball-to-material ratio of 6:1. The copper powder embedded with carbon particles is annealed in the air to decarburize and oxidize. The annealing temperature is 300°C and the holding time is 20 minutes. Spectrum analysis see figure 2 and image 3 .

Embodiment 2

[0056] In Example 2, commercially available short carbon fibers that have been degummed at 750°C for 60 minutes and electrolytic nickel powder with a particle size of 120 μm are used as ball milling raw materials. The volume percentage of short carbon fibers is 25%, and the volume percentage of electrolytic nickel powder is 75%. The diameter is 6 μm, the length is 2 mm, and the two are added to a ball mill for high-energy ball milling at a speed of 280 r / min, a ball milling time of 7 hours, and a ball-to-material ratio of 6:1. The nickel powder embedded with carbon particles is annealed in the air to decarbonize and oxidize, the annealing temperature is 500° C., and the holding time is 30 minutes to obtain porous nickel oxide powder with a porosity of 20-25%.

Embodiment 3

[0058] In Example 3, commercially available short carbon fibers that have been degummed at 800°C for 60 minutes and reduced iron powder with a particle size of 150 μm are used as raw materials for ball milling. The volume percentage of short carbon fibers is 40%, and the volume percentage of reduced iron powder is 60%. The diameter is 6 μm, the length is 2 mm, and the two are added to a ball mill for high-energy ball milling at a speed of 300 r / min, a ball milling time of 8 hours, and a ball-to-material ratio of 6:1. Embedding carbon particles into iron powder is annealed in air to decarburize and oxidize. The annealing temperature is 500° C. and the holding time is 60 minutes to obtain porous iron oxide powder with a porosity of 30-38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com