Preparation method of DNL-1 molecular sieve

A technology of aluminum phosphate molecular sieve and deionized water, which is applied in the field of molecular sieves, can solve the problems of high price of ionic liquids, difficult to achieve purity, and reduced thermal stability, and achieve the effect of commercially available raw materials, simple methods, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

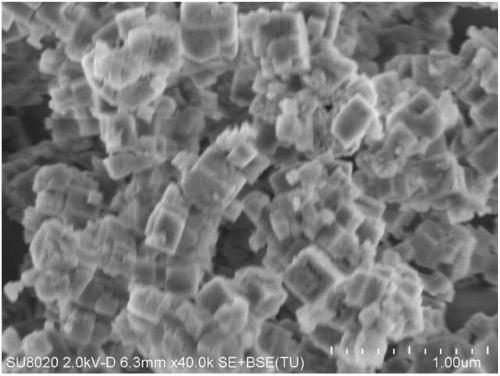

[0054] The pseudo-boehmite (Al 2 O 3 The mass percentage is 77%, aluminum source) and diethylethanolamine (the mass percentage is 99%, R1) are mixed and stirred, and then phosphoric acid (H 3 PO 4 Add 85% by mass, phosphorus source) drop by drop, stir evenly, then add water, hydrofluoric acid (40% by mass HF) and butyltrimethylammonium chloride (R2), stir evenly to make Gel, transfer the gel to the stainless steel reactor. After putting the reactor into the oven, program the temperature to 200°C for dynamic crystallization for 48 hours. After the crystallization is completed, the solid product is centrifuged, washed, and dried in air at 100° C. to obtain the original molecular sieve powder sample. The sample was analyzed by XRD (the results are shown in Table 2), and the XRD diffraction data shows that the sample is DNL-1 molecular sieve; the electron micrograph of the sample is shown in figure 1 .

[0055] The static crystallization in the embodiment is to put the reactor direc...

Embodiment 2-19

[0065] The specific ingredient ratio and crystallization conditions are shown in Table 1, and the specific ingredient process is the same as in Example 1.

[0066] The prepared samples were subjected to XRD analysis, and the data results were close to Table 2, that is, the peak position and shape were the same, and the relative kurtosis of the peak fluctuated within ±10% depending on the preparation conditions, indicating that the prepared product had the characteristics of DNL-1 structure.

experiment example 20

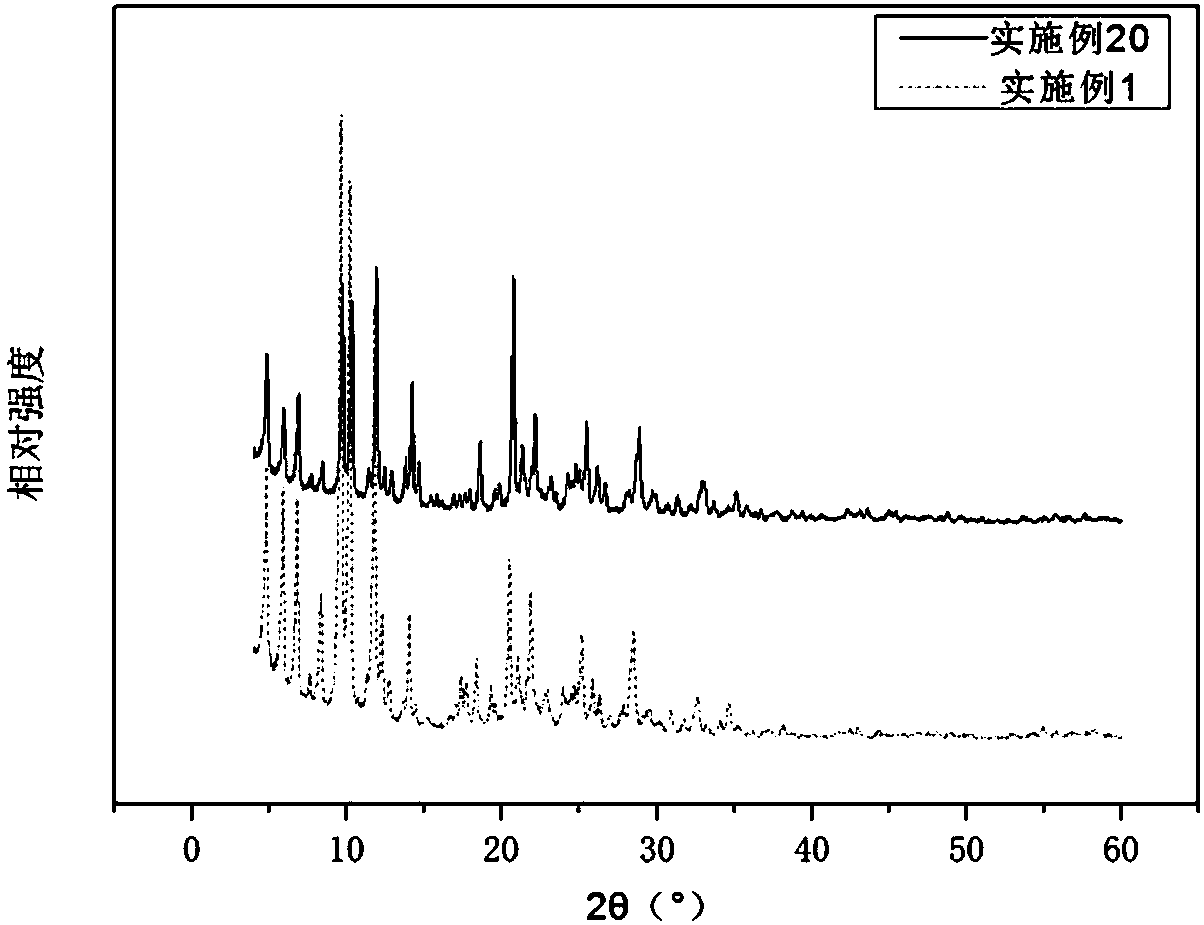

[0068] The sample obtained in Example 1 was baked in air at 550°C for 8 hours, and then subjected to XRD analysis. The results are shown in Table 3. The XRD diffraction patterns of the sample before and after baking are shown in figure 2 . The diffraction pattern shows that the positions and shapes of the diffraction peaks are approximately the same before and after the sample is calcined, indicating that the calcined product has the characteristics of aluminum phosphate molecular sieve DNL-1 structure, and also that the prepared aluminum phosphate molecular sieve DNL-1 sample has good thermal stability.

[0069] Table 3 XRD results

[0070]

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com