Synthesizing and application methods of sodium zirconate

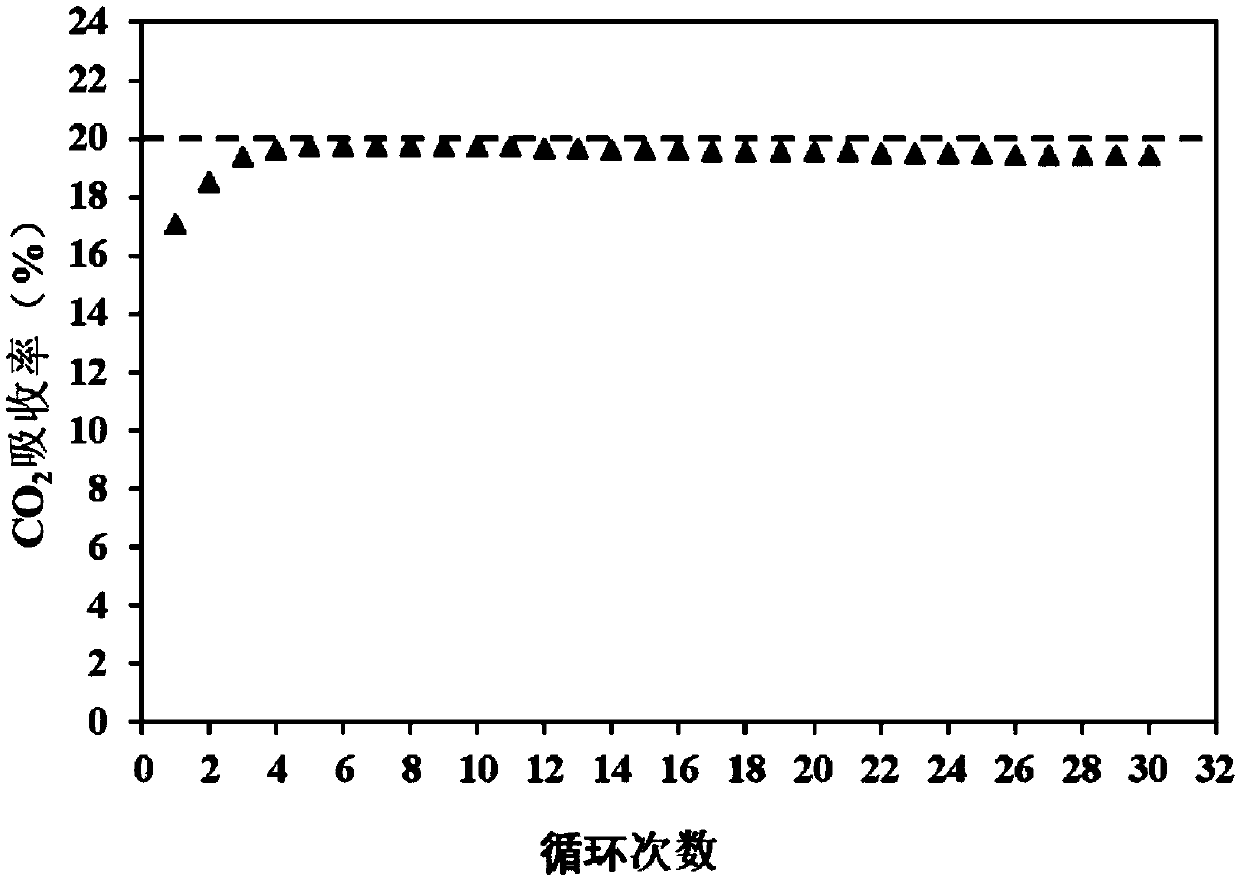

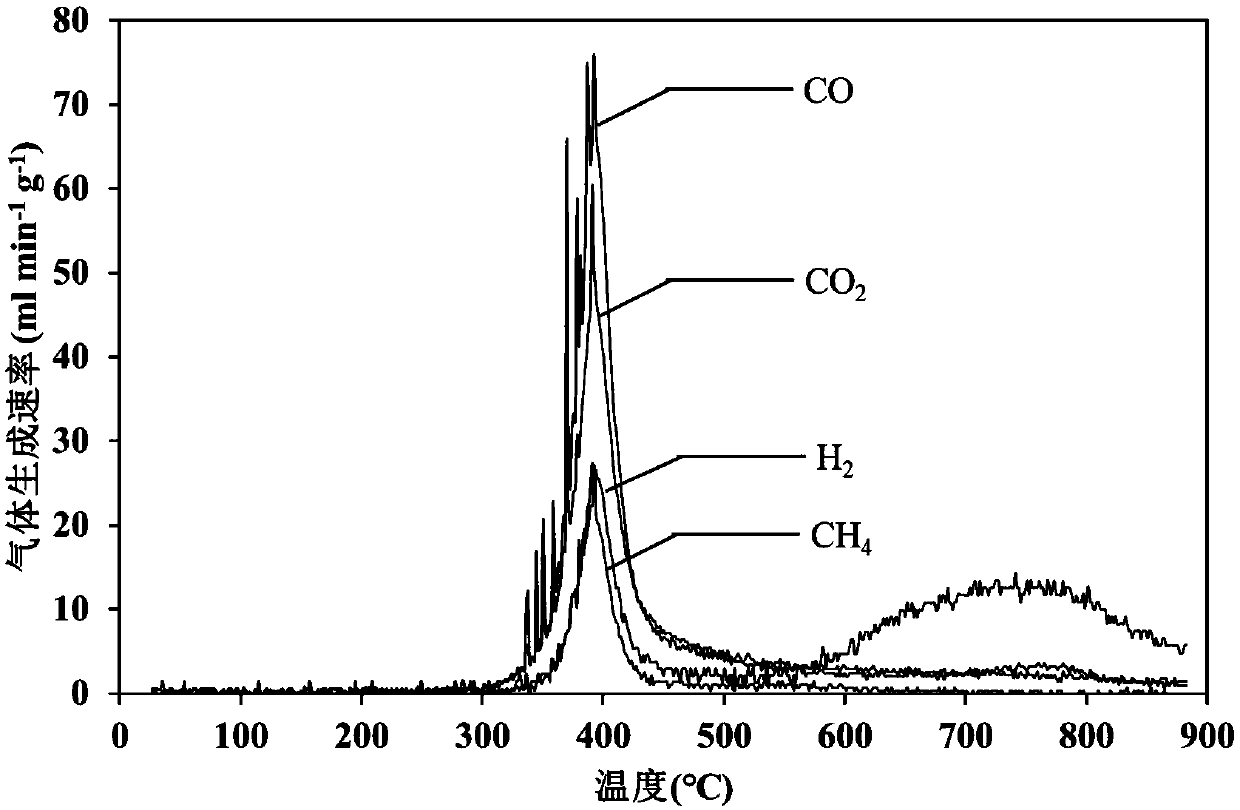

A synthesis method, sodium zirconate technology, applied in zirconium compounds, separation methods, chemical instruments and methods, etc., can solve problems such as sintering and rapid decline in adsorption capacity, achieve cost savings, realize reduction and resource utilization, and promote Effect of pyrolysis hydrogen production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

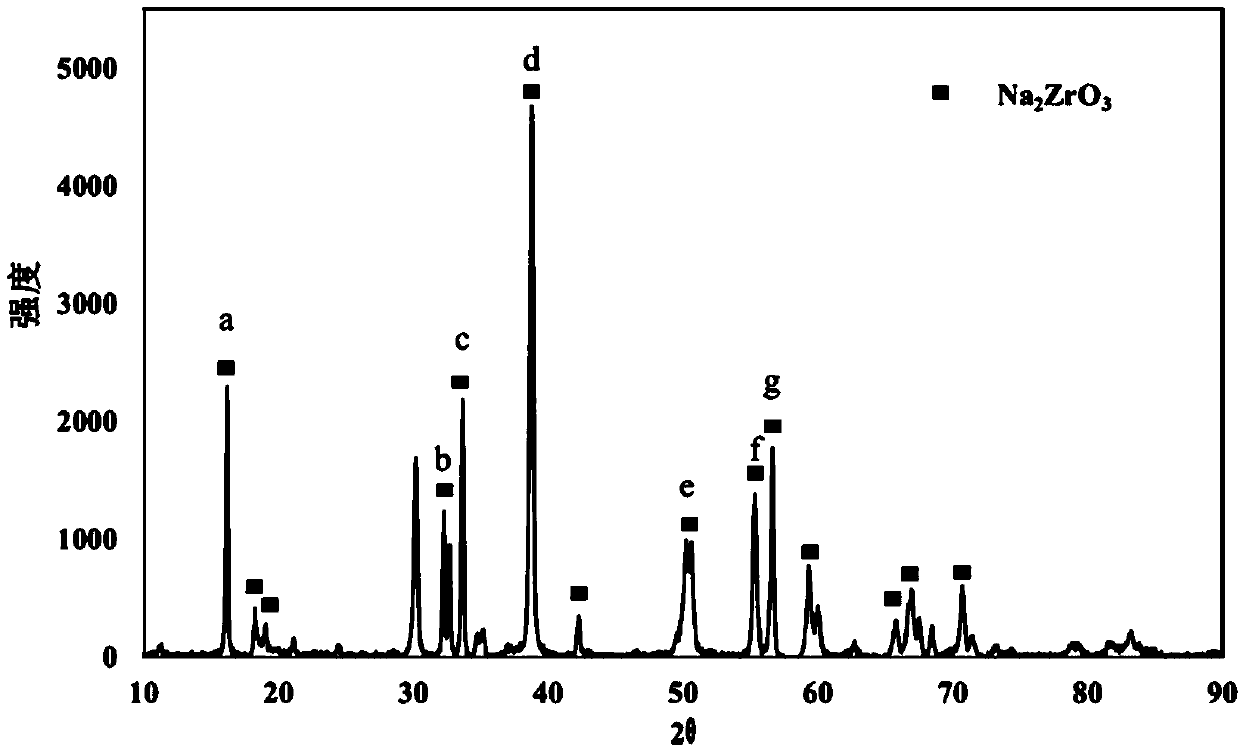

Embodiment 1

[0041] Weighed 1.1476g of sodium carbonate solid and 1.4389g of crown material waste. After X-ray fluorescence (XRD) analysis of the crown material waste, it was found that the zirconia content was 92.53%. After mixing, they were placed in a ball mill for ball milling. The rotational speed of the ball mill was 500 rpm. The ball milling time is 2h. The resulting powder is then calcined in a muffle furnace. The calcination procedure in the muffle furnace is to raise the temperature from 20°C to 850°C, and calcine at a constant temperature of 850°C for 6h. The product can be obtained.

Embodiment 2

[0043] Weigh 1.3779g of sodium carbonate solid and 1.4389g of dental crown material waste. After X-ray fluorescence (XRF) analysis of the dental crown material waste, it can be known that the zirconia content is 92.53%, and they are mixed and placed in a ball mill for ball milling . The rotational speed of the ball mill was 550 rpm. The ball milling time is 1.5h. The resulting powder is then calcined in a muffle furnace. The calcination temperature in the muffle furnace was 800°C, and the calcination was carried out at a constant temperature of 800°C for 5h. The product can be obtained.

Embodiment 3

[0045] Weighed 1.1476g of sodium carbonate powder and 1.4389g of crown material waste. After X-ray fluorescence (XRF) analysis of the crown material waste, it was found that the zirconia content was 92.53%, and then the obtained powder was calcined. The calcination temperature is 750°C, and the calcination is carried out at a constant temperature of 750°C for 8 hours. The product can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com