Reverse osmosis concentrated water enhanced treatment method and device

A technology of reverse osmosis concentrated water and enhanced treatment, applied in chemical instruments and methods, special compound water treatment, biological water/sewage treatment, etc., can solve the problems of secondary pollution, high treatment cost, high energy consumption, etc. Stable, good effect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

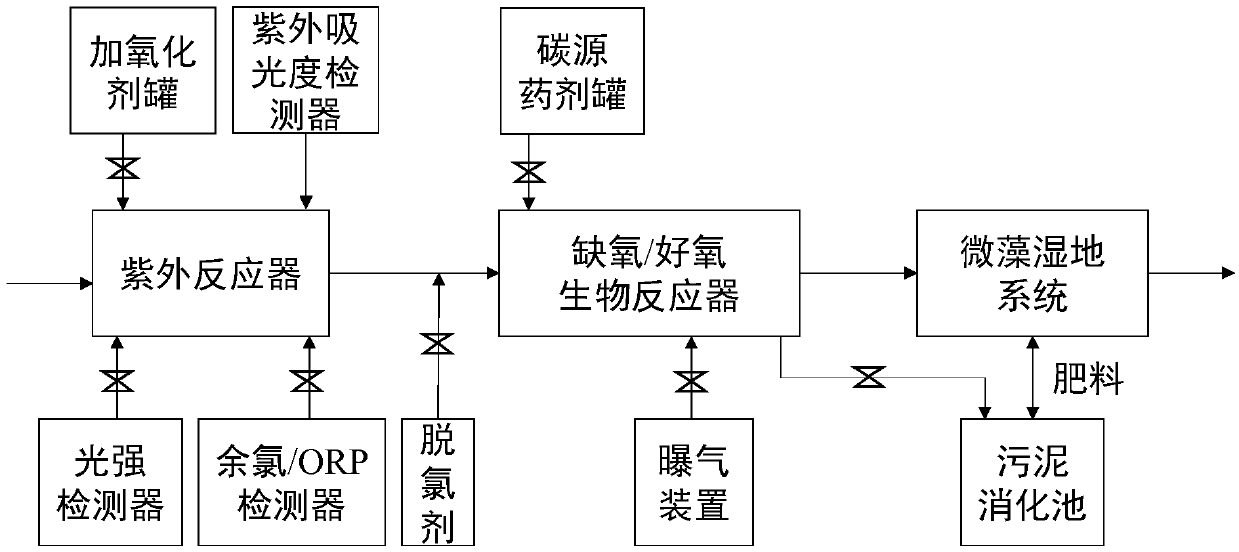

Method used

Image

Examples

example

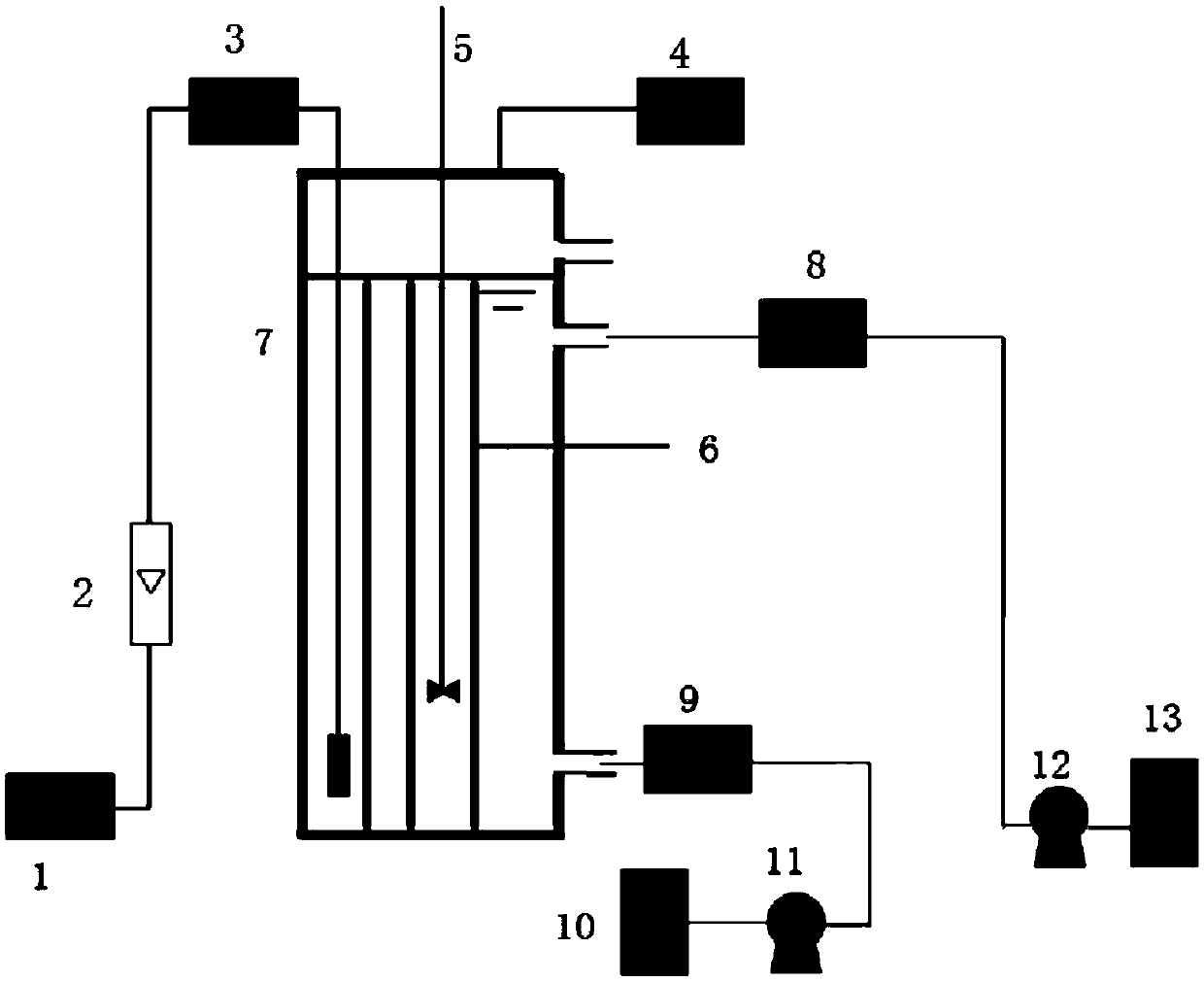

[0067] A UV reactor was used for UV / chlorine oxidation reverse osmosis concentrated water experiment. The reverse osmosis concentrated water is taken from a reclaimed water plant and is reverse osmosis concentrated water. UV irradiation power is 1mW / cm 2 , The irradiation time is 10 minutes, and the UV dose is 600mJ / cm 2 . The dosage of sodium hypochlorite is 30mg-Cl 2 / L. During the reaction, monitor the absorbance of the effluent at 254nm (ie UV 254 Value), the result is as Figure 5 Shown. The results show that the UV light of single ultraviolet light has 254 The removal effect is very poor; the chlorine dosage is 30mg-Cl 2 / L, separate chlorine oxidation and UV / Chlorine vs. UV 254 The removal rate is 30% and 49% respectively; visible, ultraviolet / chlorine oxidation technology improves the removal rate of organic matter in reverse osmosis concentrated water.

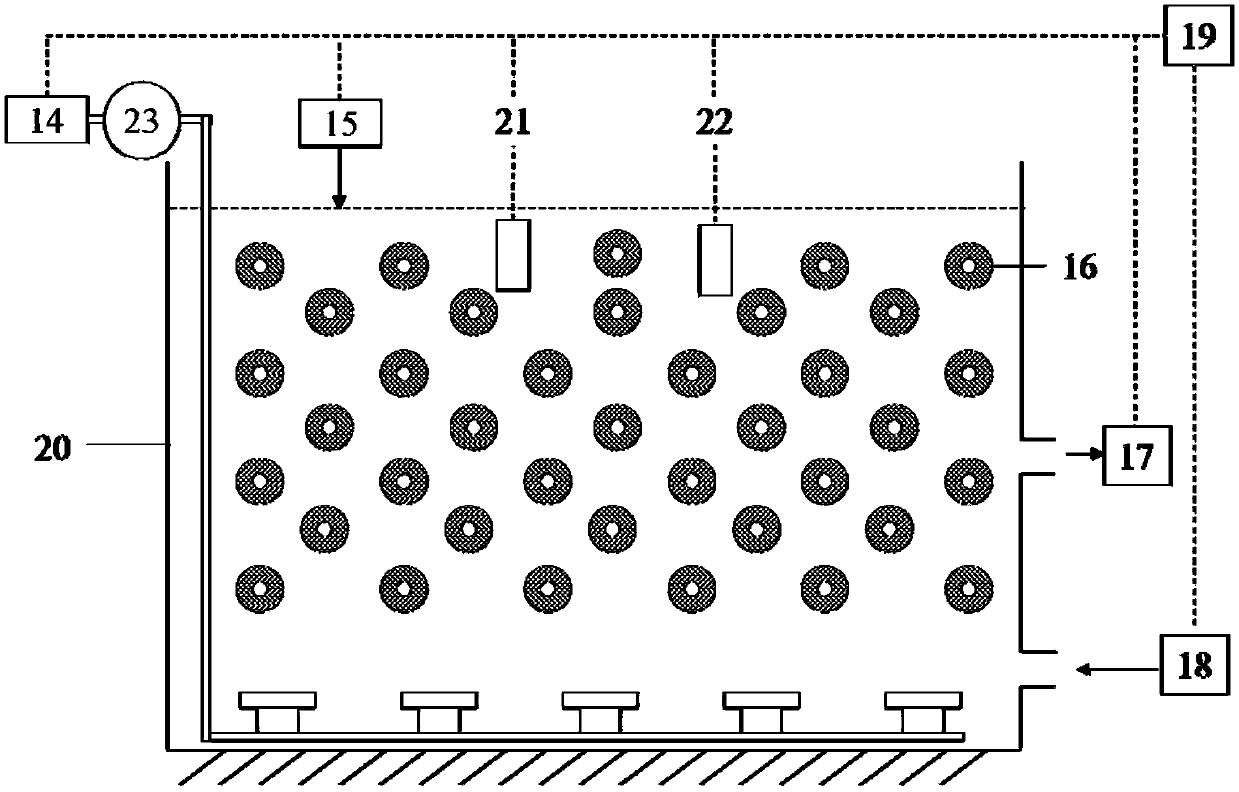

[0068] SBR reactor is used to treat reverse osmosis concentrated water, and the reactor operation cycle is 4h. Unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com