Method for refining cyclohexanone oxime gaseous-phase rearrangement products

A technology of cyclohexanone oxime and gas phase, which is applied in the field of refined cyclohexanone oxime gas phase rearrangement products, which can solve the problems of additional recovery devices and the inability to meet the national high-grade product index of caprolactam products, and achieve the effect of saving investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

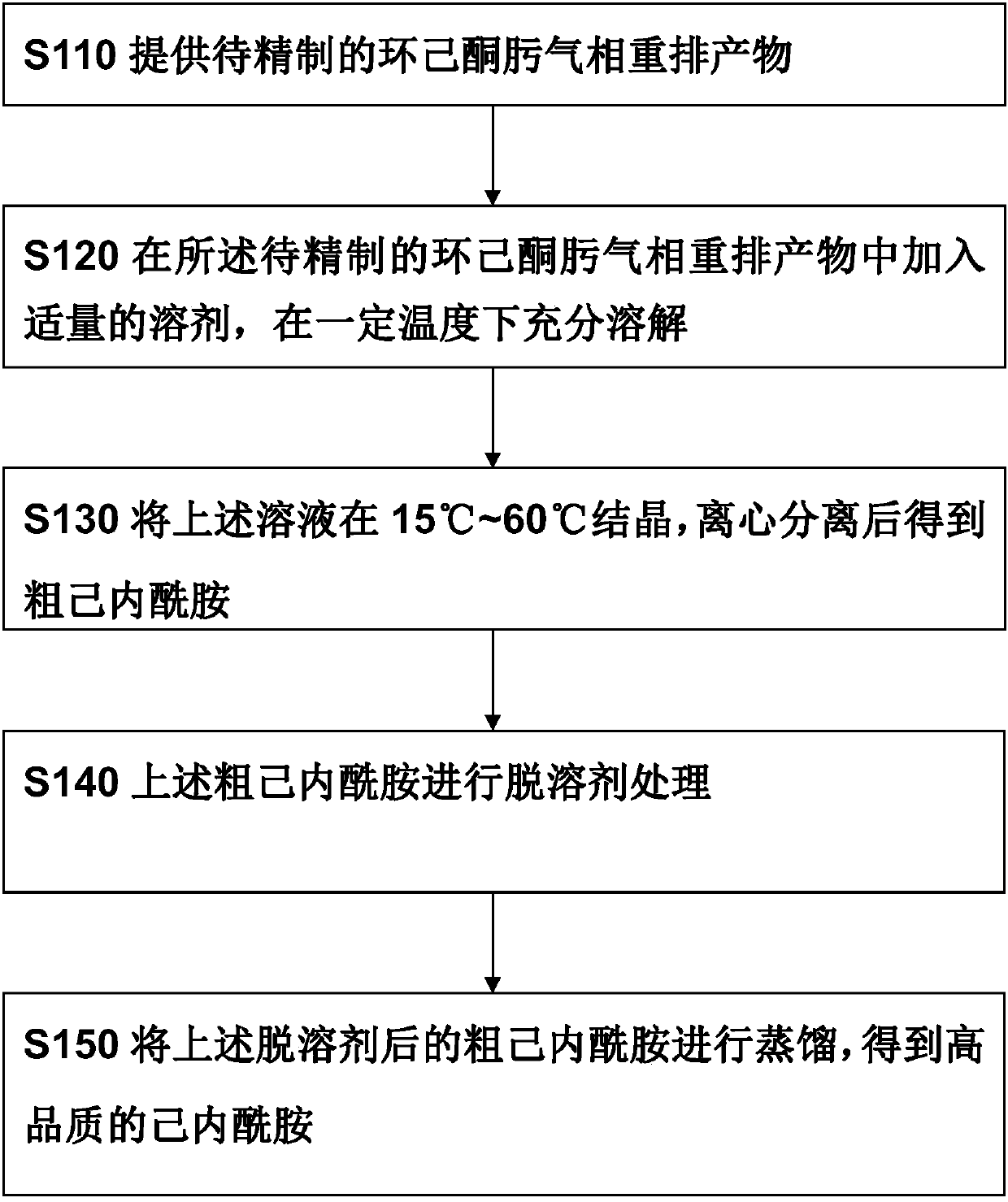

Image

Examples

Embodiment 1

[0081] Provide the gas phase rearrangement product of cyclohexanone oxime to be refined, add diisopropyl ether and methanol with 6% mass of diisopropyl ether to the gas phase rearrangement product of cyclohexanone oxime, the mass ratio of rearrangement product to total solvent The ratio is 1.5:1, fully dissolved at 67°C, then crystallized at 15°C, and preliminarily refined caprolactam is obtained after centrifugation. The crude hexane is desolventized under the operating conditions of the negative pressure of the desolventization tower being -80kpa, the temperature of the tower bottom is 100°C, and the temperature of the top of the tower is 70°C; the caprolactam after desolvation is in the distillation tower Distillation is carried out under the operating condition of temperature control at 130° C. to obtain the final product, and the recovery rate of caprolactam is 99%. The recovered caprolactam has a purity greater than 99.99%.

Embodiment 2

[0083] Provide the gas phase rearrangement product of cyclohexanone oxime to be refined, add diisopropyl ether and methanol with 6% mass of diisopropyl ether to the gas phase rearrangement product of cyclohexanone oxime, the mass ratio of rearrangement product to total solvent The ratio is 1:1.5, fully dissolved at 67°C, then crystallized at 15°C, and preliminarily refined caprolactam is obtained after centrifugation. The crude hexane is desolventized under the operating conditions of the negative pressure of the desolventization tower being -80kpa, the temperature of the tower bottom is 100°C, and the temperature of the top of the tower is 70°C; the caprolactam after desolvation is in the distillation tower Distillation was carried out under the operating condition of temperature control at 130° C. to obtain the final product, and the recovery rate of caprolactam was 83%. The recovered caprolactam has a purity greater than 99.99%. Compared with Example 1, increasing the rati...

Embodiment 3

[0093] Provide the gas phase rearrangement product of cyclohexanone oxime to be refined, add diisopropyl ether and methanol with a mass of 0.5% of diisopropyl ether to the gas phase rearrangement product of cyclohexanone oxime, the mass ratio of the rearrangement product to the total solvent The ratio is 1.5:1, fully dissolved at 67°C, then crystallized at 15°C, and preliminarily refined caprolactam is obtained after centrifugation. The crude hexane is desolventized under the operating conditions of the negative pressure of the desolventization tower being -80kpa, the temperature of the tower bottom is 100°C, and the temperature of the top of the tower is 70°C; the caprolactam after desolvation is in the distillation tower Distillation is carried out under the operating condition of temperature control at 130° C. to obtain the final product, and the recovery rate of caprolactam is 99%. The recovered caprolactam has a purity of 99.91%. Compared with Comparative Example 2, addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com