Method and device for preparing powder for selective laser melting by recovering waste aluminum and product

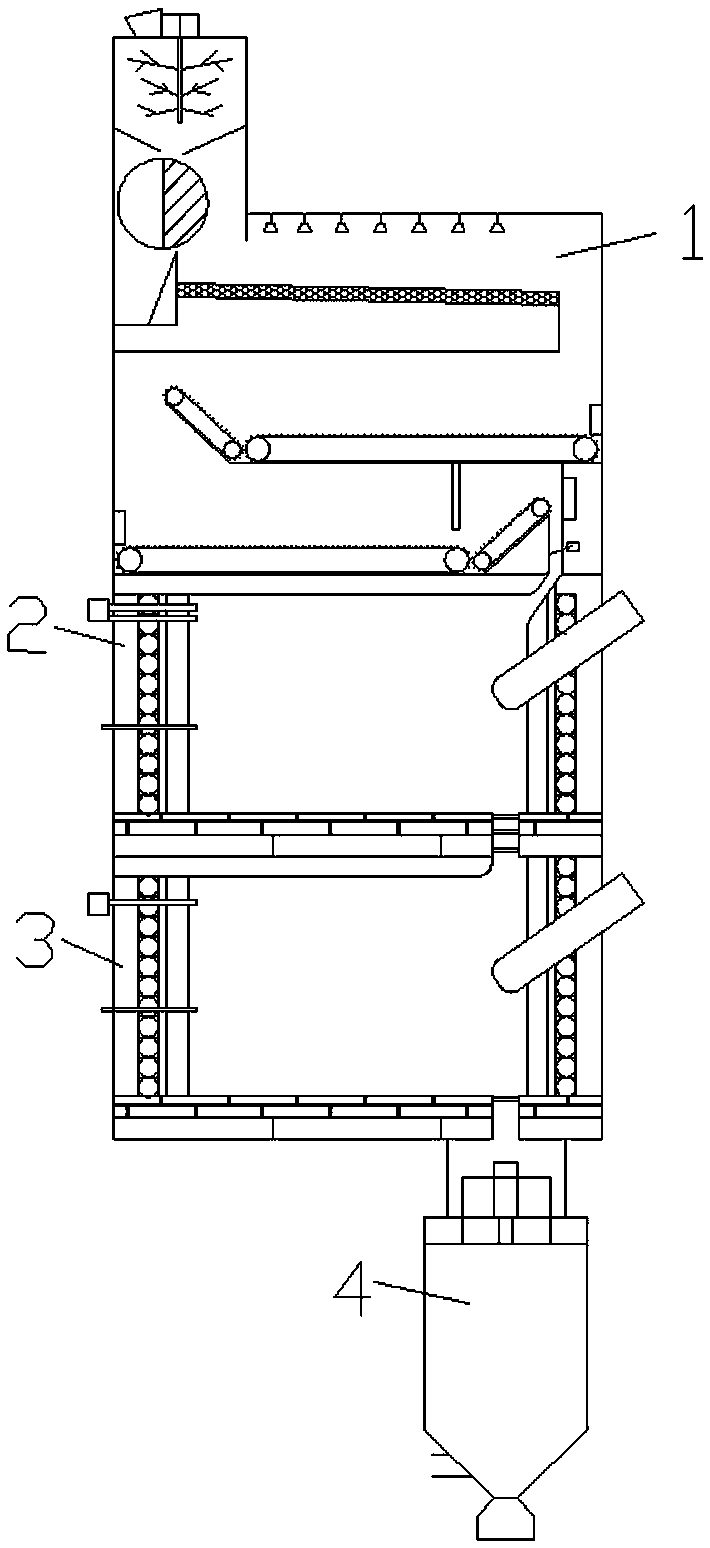

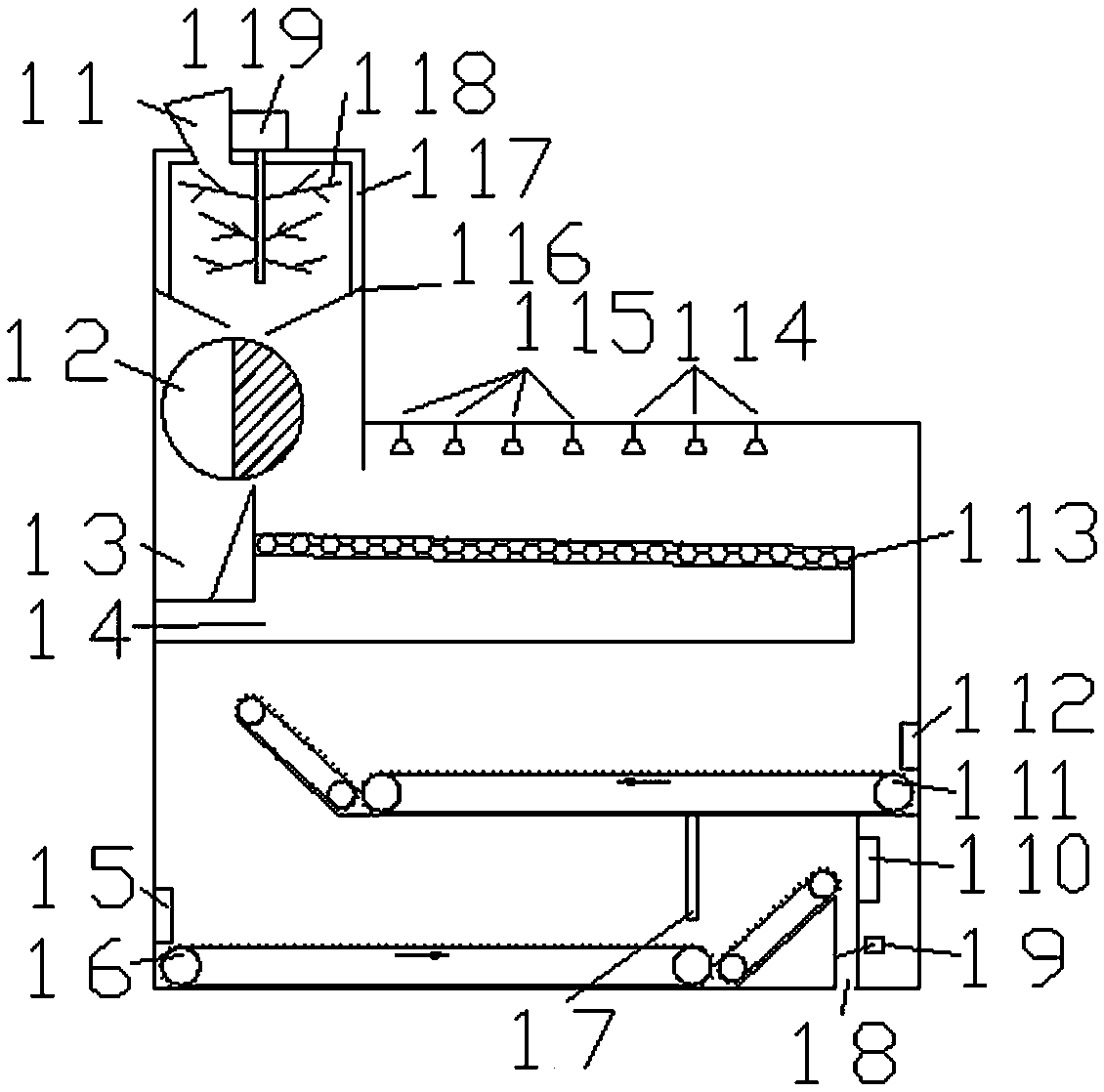

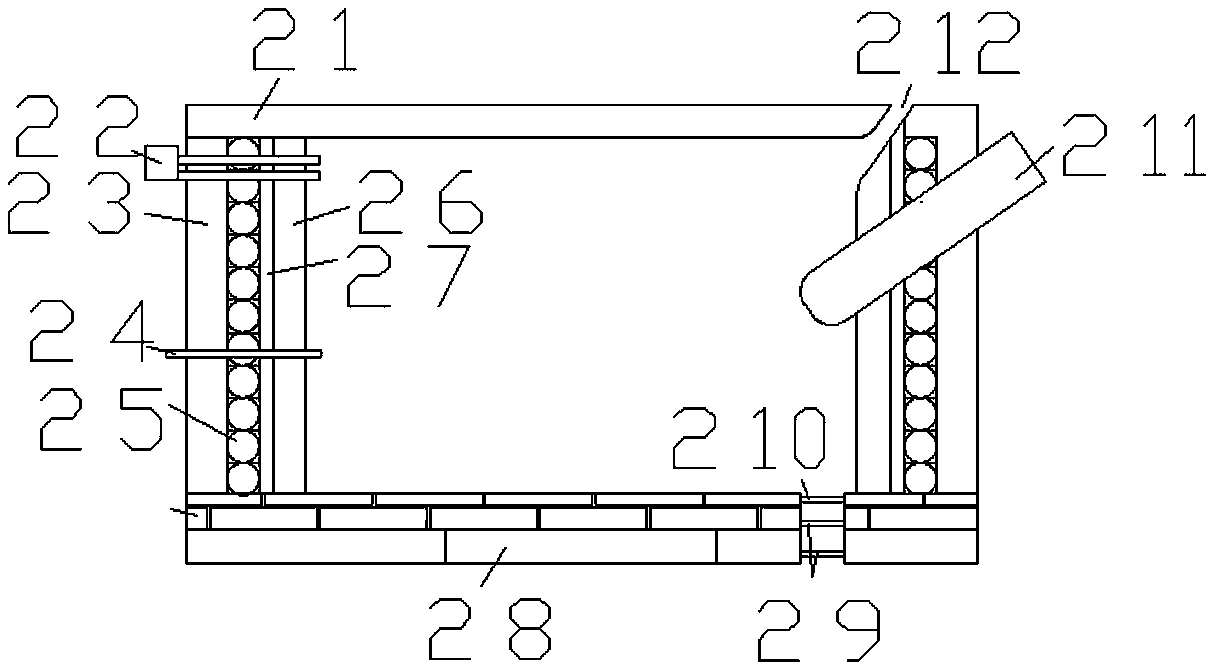

A laser selective melting and aluminum recycling technology, applied in the direction of process efficiency improvement, additive processing, etc., can solve problems such as environmental pollution and resource waste, and achieve the effect of low oxygen content, fewer links and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for recycling waste aluminum to prepare powder for laser selective melting, the steps are as follows:

[0048] 1) Crush the waste aluminum into aluminum chips with a particle size of 1-5cm, and then perform electromagnetic iron removal on the aluminum chips, then soak the aluminum chips in acetone to remove oil, and wash them with water after degreasing;

[0049] The washed aluminum chips are immersed in the molten paint stripping powder at 800°C for 1 min, and the paint stripping powder is composed of sodium carbonate and magnesium chloride with a mass ratio of 1:1;

[0050] The depainted aluminum chips are immersed in a cleaning solution for ultrasonic cleaning to remove the oxide film on the surface of the aluminum chips, and the cleaning solution is composed of absolute ethanol and ethyl bromide with a volume ratio of 1:9;

[0051] The aluminum chips after removing the oxide film are dried with a direct heating drum dryer, the drying rotation speed is 1r / mi...

Embodiment 2

[0060] A method for recycling waste aluminum to prepare powder for laser selective melting, the steps are as follows:

[0061] 1) Crush the waste aluminum into aluminum chips with a particle size of 1-5cm, and then perform electromagnetic iron removal on the aluminum chips, then soak the aluminum chips in acetone to remove oil, and wash them with water after degreasing;

[0062] The washed aluminum chips are immersed in the molten paint stripping powder at 850°C for 5 minutes, and the paint stripping powder is composed of sodium carbonate and magnesium chloride with a mass ratio of 1:1;

[0063] The depainted aluminum chips are immersed in a cleaning solution for ultrasonic cleaning to remove the oxide film on the surface of the aluminum chips, and the cleaning solution is composed of absolute ethanol and ethyl bromide with a volume ratio of 1:9;

[0064] The aluminum shavings after removing the oxide film are dried with a direct heating drum dryer, the drying rotation speed i...

Embodiment 3

[0073] A method for recycling waste aluminum to prepare powder for laser selective melting, the steps are as follows:

[0074] 1) Crush the waste aluminum into aluminum chips with a particle size of 1-5cm, and then perform electromagnetic iron removal on the aluminum chips, then soak the aluminum chips in acetone to remove oil, and wash them with water after degreasing;

[0075] The washed aluminum chips are immersed in the molten paint stripping powder at 850°C for 1-5 minutes, and the paint stripping powder is composed of sodium carbonate and magnesium chloride with a mass ratio of 1:1;

[0076] The depainted aluminum chips are immersed in a cleaning solution for ultrasonic cleaning to remove the oxide film on the surface of the aluminum chips, and the cleaning solution is composed of absolute ethanol and ethyl bromide with a volume ratio of 1:9;

[0077]The aluminum shavings after removing the oxide film are dried with a direct heating drum dryer, the drying rotation speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com