Rapid detecting method for furfural compounds in dairy products

A detection method and technology for dairy products, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as high price and narrow linear range, and achieve the effects of improving detection sensitivity, fast and efficient solvents, and shortening analysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

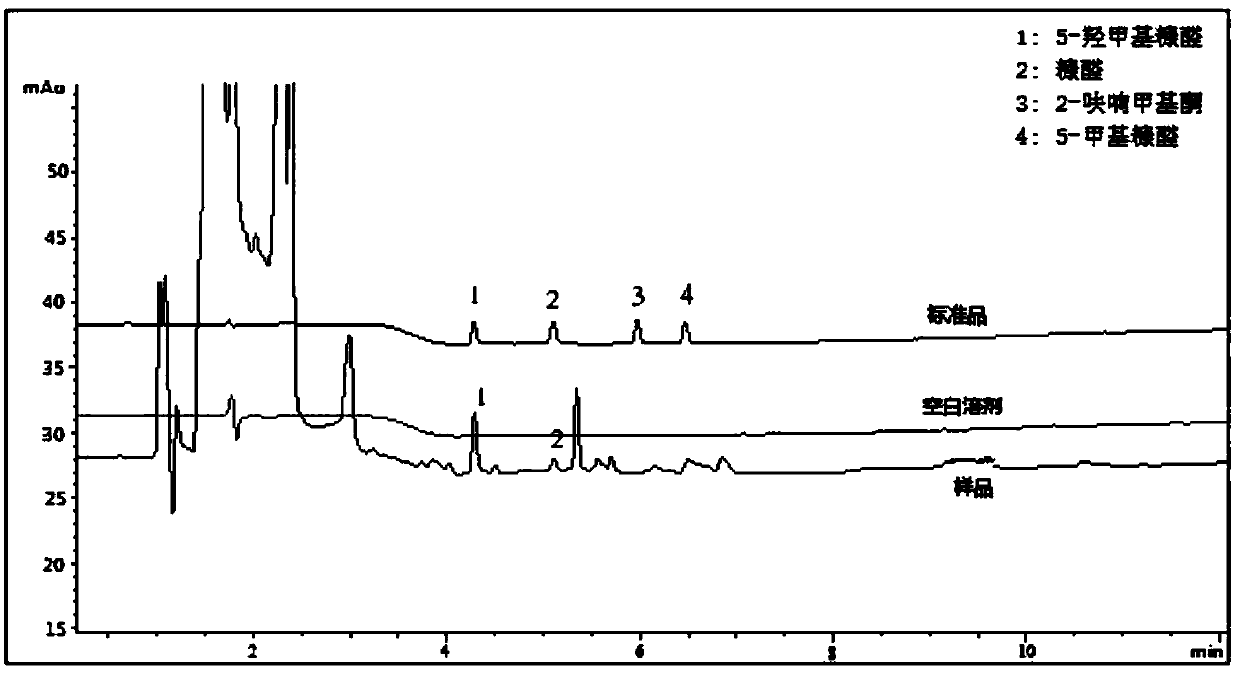

[0038] The detection method of furfural compounds in milk powder includes the following steps:

[0039] (1) Weigh 2.25g milk powder sample, add water to 15g and mix well, add 5mL0.15mol / L oxalic acid and heat it in a water bath at 100℃ on the same day for 25min, and cool to room temperature;

[0040] (2) Then add 3mL 40g / mL trichloroacetic acid solution A, shake for 10min, centrifuge at 4.355g for 15min; take the supernatant into a 25mL volumetric flask, add 5mL4g / mL trichloroacetic acid solution B to the filter residue, shake for 10min, 4. Centrifuge at 355g for 15min; combine the supernatants and add 4g / mL trichloroacetic acid solution B to the mark;

[0041] (3) Take an appropriate amount of liquid and pass it through a 0.45μm nylon filter membrane and enter it into a chromatograph for analysis. Choose a reversed-phase C18 chromatographic column with a particle size of 3μm. Column: Waters Atlantis T3 (3.0mm×15cm, 3μm); mobile phase: mobile phase A is water, mobile phase B is acet...

Embodiment 2

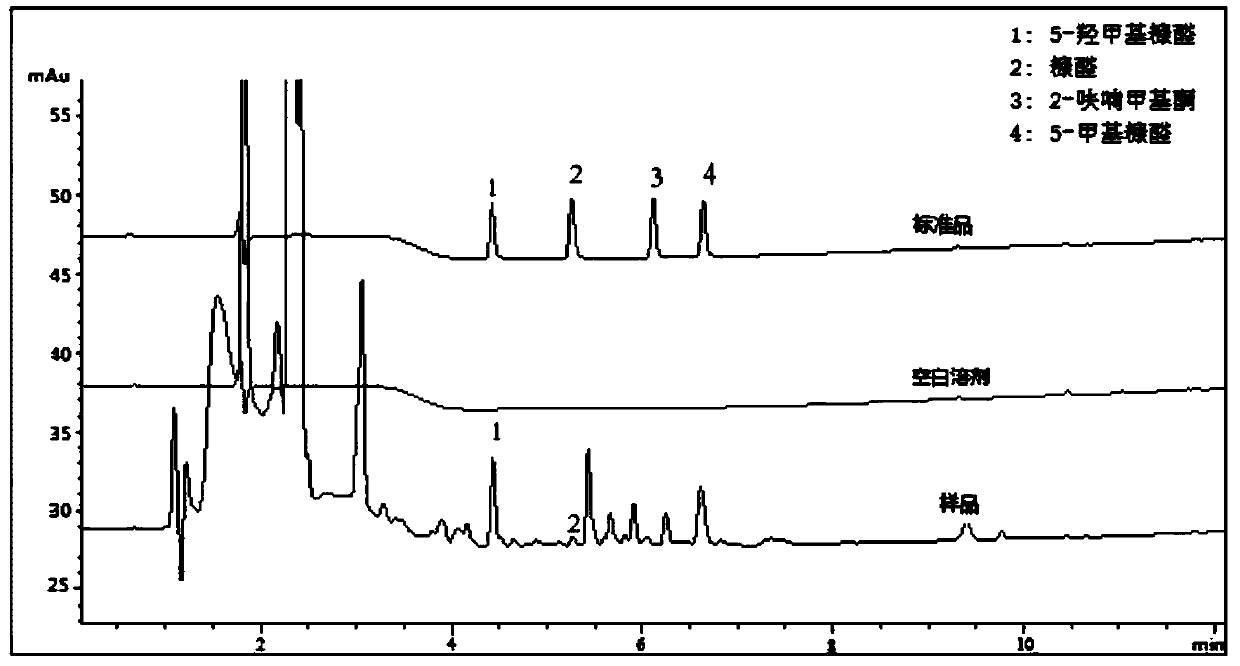

[0044] The detection method of furfural compounds in liquid milk includes the following steps:

[0045] (1) Weigh 15g of liquid milk sample, add 4.5mL0.16mol / L, configure oxalic acid on the same day, heat it in a 90℃ water bath for 30min, and cool to room temperature;

[0046] (2) Then add 3mL of 35g / mL trichloroacetic acid solution A, shake for 10min, 4g centrifugation for 18min; take the supernatant into a 25mL volumetric flask, add 5mL3.5g / mL trichloroacetic acid solution B to the filter residue, shake for 10min Centrifuge at 4g for 18min; combine the supernatants and add 3.5g / mL trichloroacetic acid solution B to the mark.

[0047] (3) Take an appropriate amount of liquid and pass it through a 0.45μm nylon filter membrane and enter it into a chromatograph for analysis. Choose a reversed-phase C18 chromatographic column with a filler particle size of 2.7μm. Column: Waters Atlantis T3 (2.8mm×12cm, 2.8μm); mobile phase: mobile phase A is water, mobile phase B is acetonitrile; gradi...

Embodiment 3

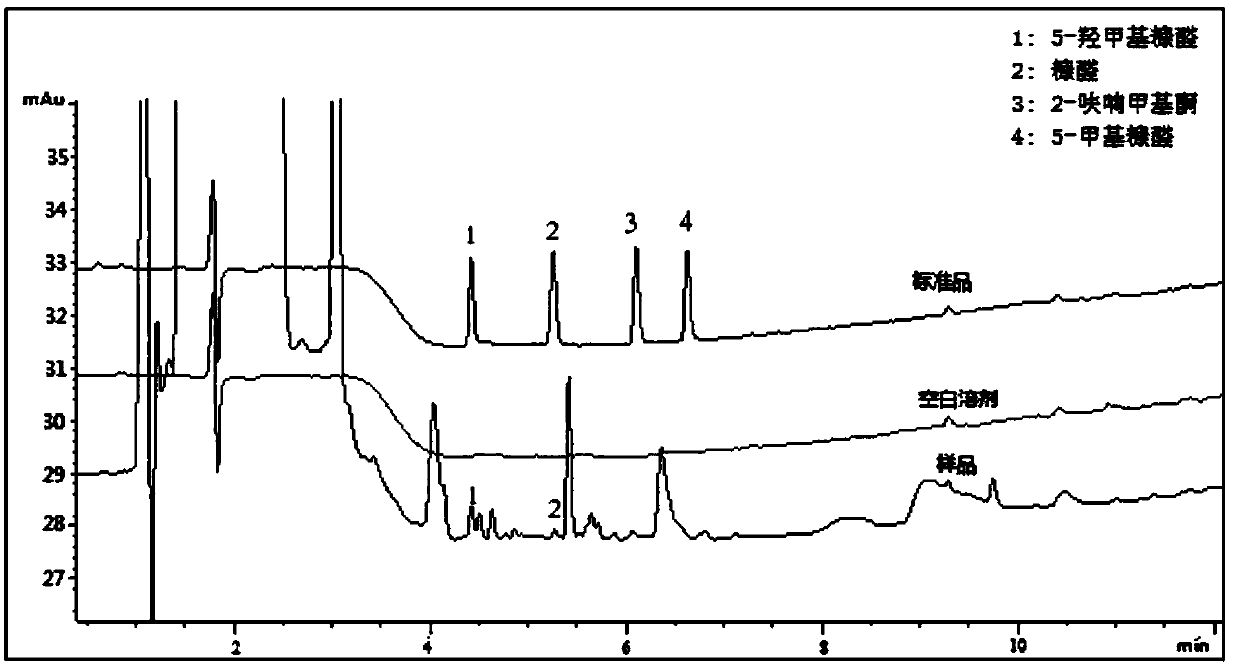

[0050] The detection method of furfural compounds in pasteurized milk includes the following steps:

[0051] (1) Weigh 15g of pasteurized milk sample, add 7.5mL0.12mol / L oxalic acid on the same day to 120℃ water bath heating for 20min, and cool to room temperature;

[0052] (2) Then add 3mL of 45g / mL trichloroacetic acid solution A, shake for 12min, 5g centrifuge for 18min; take the supernatant into a 25mL volumetric flask, add 5mL4.5g / mL trichloroacetic acid solution B to the filter residue, shake for 12min Centrifuge at 5g for 18min; combine the supernatants and add 4.5g / mL trichloroacetic acid solution B to the mark.

[0053] (3) Take an appropriate amount of liquid and pass it through a 0.45μm nylon filter membrane and enter it into a chromatograph for analysis. Choose a reversed-phase C18 chromatographic column with a filler particle size of 3.5μm. Column: WatersAtlantisT3 (3.2mm×18cm, 3.2μm); mobile phase: mobile phase A is water, mobile phase B is acetonitrile; gradient eluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com