Hybrid-phase structure layered oxide material and preparation method and application thereof

A technology of oxides and structural layers, applied in the field of materials, can solve problems such as rising battery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

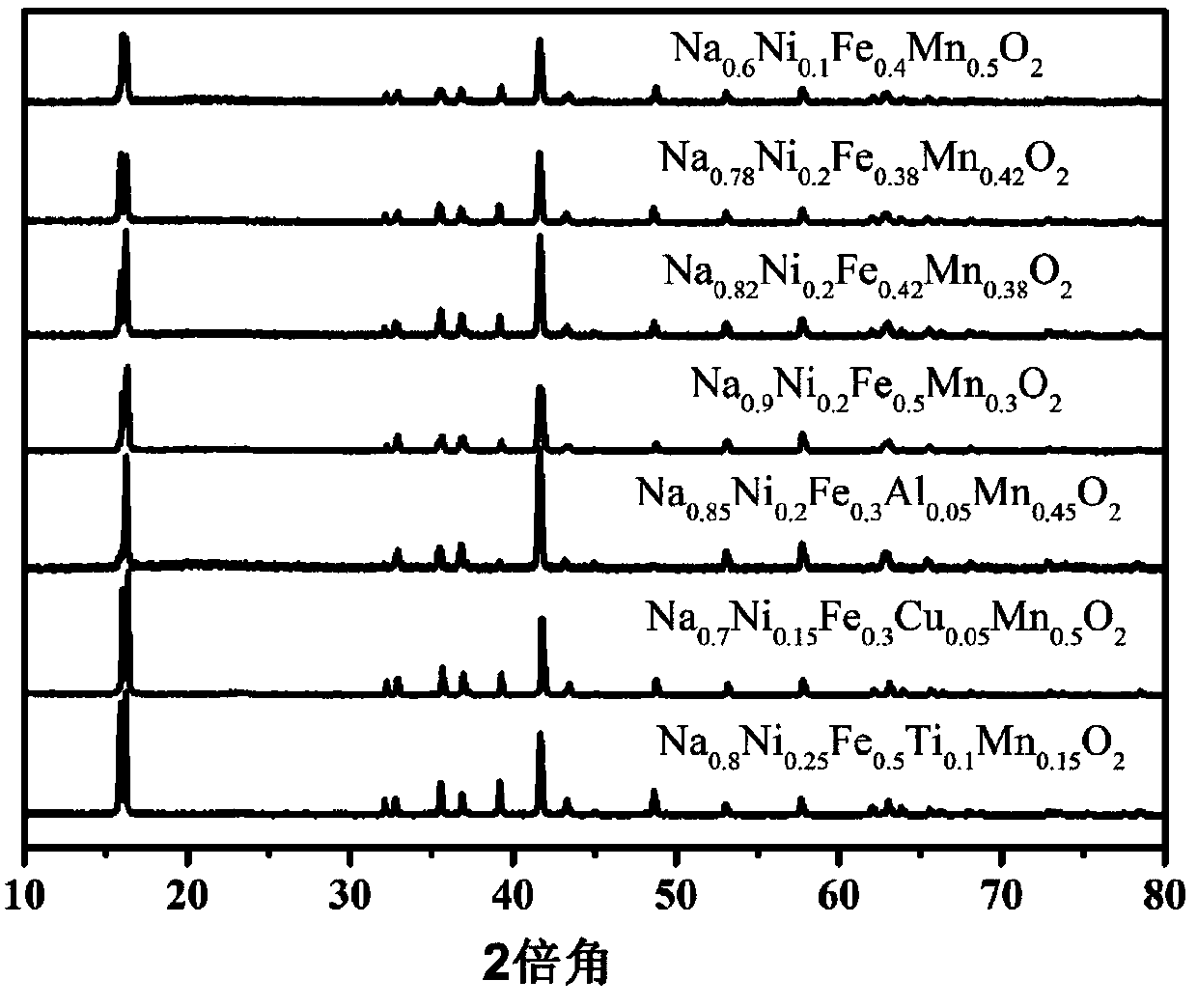

[0064] Embodiment 1 of the present invention provides a layered oxide material with mixed phase structure, the general chemical formula is: Na x Ni i Fe j mn k m y o 2+β .

[0065] Among them, M is an element for doping and replacing the transition metal site, specifically Li + , Cu 2+ , Mg 2+ , Mn 2+ , Zn 2+ ,Co 2 + , Ca 2+ , Ba 2+ ,Sr 2+ , Mn 3+ , Al 3+ , B 3+ , Cr 3+ ,Co 3+ , V 3+ , Zr 4+ , Ti 4+ , Sn 4+ , V 4+ , Mo 4+ , Mo 5+ , Ru 4+ , Nb 5+ , Si 4+ , Sb 5+ , Nb5+ , Mo 6+ , Te 6+ one or more of

[0066] x, y, i, j, k, and β are the molar percentages of the corresponding elements; the relationship between x, y, i, j, k, and β satisfies y+i+j+k=1, and x +my+2i+3j+4k=2(2+β); where 0.6≤x≤0.9; 0<i≤0.3; 0<j≤0.5; 0<k≤0.5; -0.02≤β≤0.02; m is the valence state of M; in a preferred embodiment, 0.76≤x≤0.8; 0.1<i≤0.3; 0<j≤0.5; 0<k≤0.5; -0.02≤β≤0.02.

[0067] The structure of the mixed-phase layered oxide is a mixed phase of P2 and O3, and the space g...

Embodiment 2

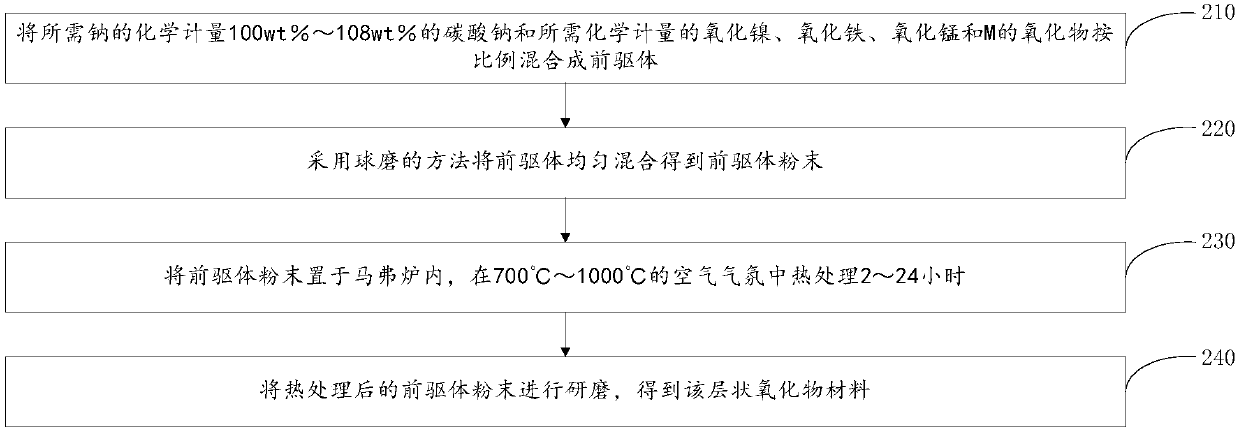

[0070] Embodiment 2 of the present invention provides a method for preparing a layered oxide material with a mixed phase structure, which is a solid phase method, such as figure 2 shown, including:

[0071] Step 210, mixing sodium carbonate with a stoichiometric amount of 100wt% to 108wt% of sodium and required stoichiometric amounts of nickel oxide, iron oxide, manganese oxide and M oxide in proportion to form a precursor;

[0072] M is specifically Li + , Cu 2+ , Mg 2+ , Mn 2+ , Zn 2+ ,Co 2+ , Ca 2+ , Ba 2+ ,Sr 2+ , Mn 3+ , Al 3+ , B 3+ , Cr 3+ ,Co 3+ , V 3+ , Zr 4+ , Ti 4+ , Sn 4+ , V 4+ , Mo 4+ , Mo 5+ , Ru 4+ , Nb 5+ , Si 4+ , Sb 5+ , Nb 5+ , Mo 6+ , Te 6+ one or more of

[0073] Step 220, uniformly mixing the precursor by ball milling to obtain precursor powder;

[0074] Step 230, placing the precursor powder in a muffle furnace, and heat-treating it in an air atmosphere at 700° C. to 1000° C. for 2 to 24 hours;

[0075] Step 240, grinding ...

Embodiment 3

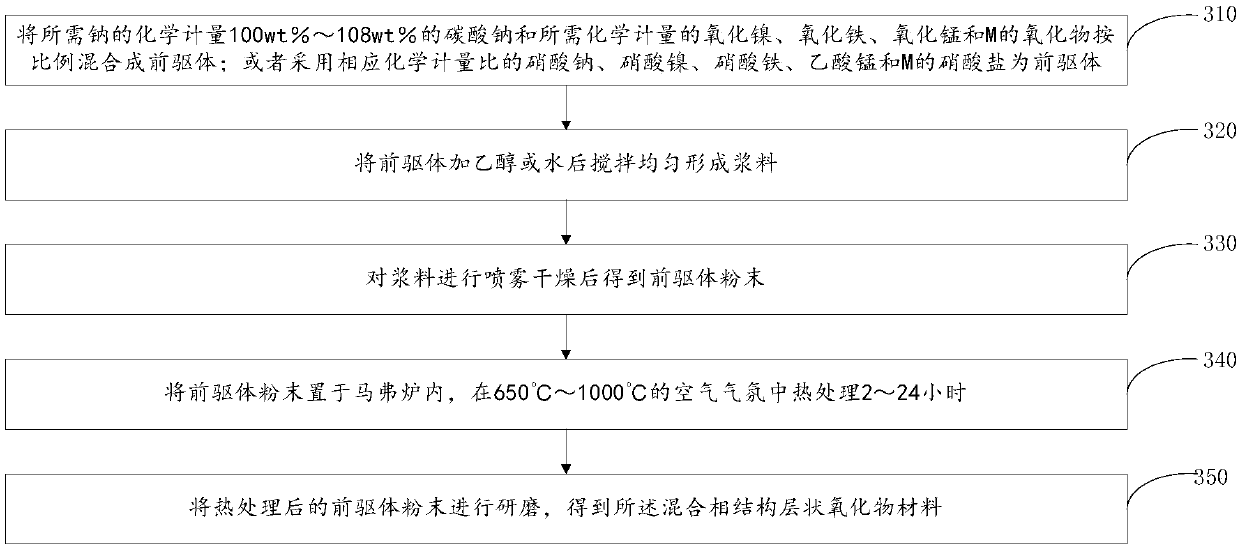

[0077] Embodiment 3 of the present invention provides a preparation method of a layered oxide material with a mixed phase structure, spray drying method, such as image 3 shown, including:

[0078] Step 310, mix the required stoichiometric sodium carbonate of 100wt%-108wt% sodium carbonate and the required stoichiometric nickel oxide, iron oxide, manganese oxide and M oxide in proportion to form a precursor; or use the corresponding stoichiometric ratio Sodium nitrate, nickel nitrate, iron nitrate, manganese acetate and M nitrate are precursors;

[0079] The M is specifically Li + , Cu 2+ , Mg 2+ , Mn 2+ , Zn 2+ ,Co 2+ , Ca 2+ , Ba 2+ ,Sr 2+ , Mn 3+ , Al 3+ , B 3+ , Cr 3+ ,Co 3 + , V 3+ , Zr 4+ , Ti 4+ , Sn 4+ , V 4+ , Mo 4+ , Mo 5+ , Ru 4+ , Nb 5+ , Si 4+ , Sb 5+ , Nb 5+ , Mo 6+ , Te 6+ one or more of

[0080] Step 320, adding ethanol or water to the precursor and stirring evenly to form a slurry;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com