Potassium feldspar and soda feldspar flour production line

A feldspar powder and production line technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of small particles not being crushed, iron removal is not clean enough, and the crushing effect is not ideal, so as to improve the purity and crushing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

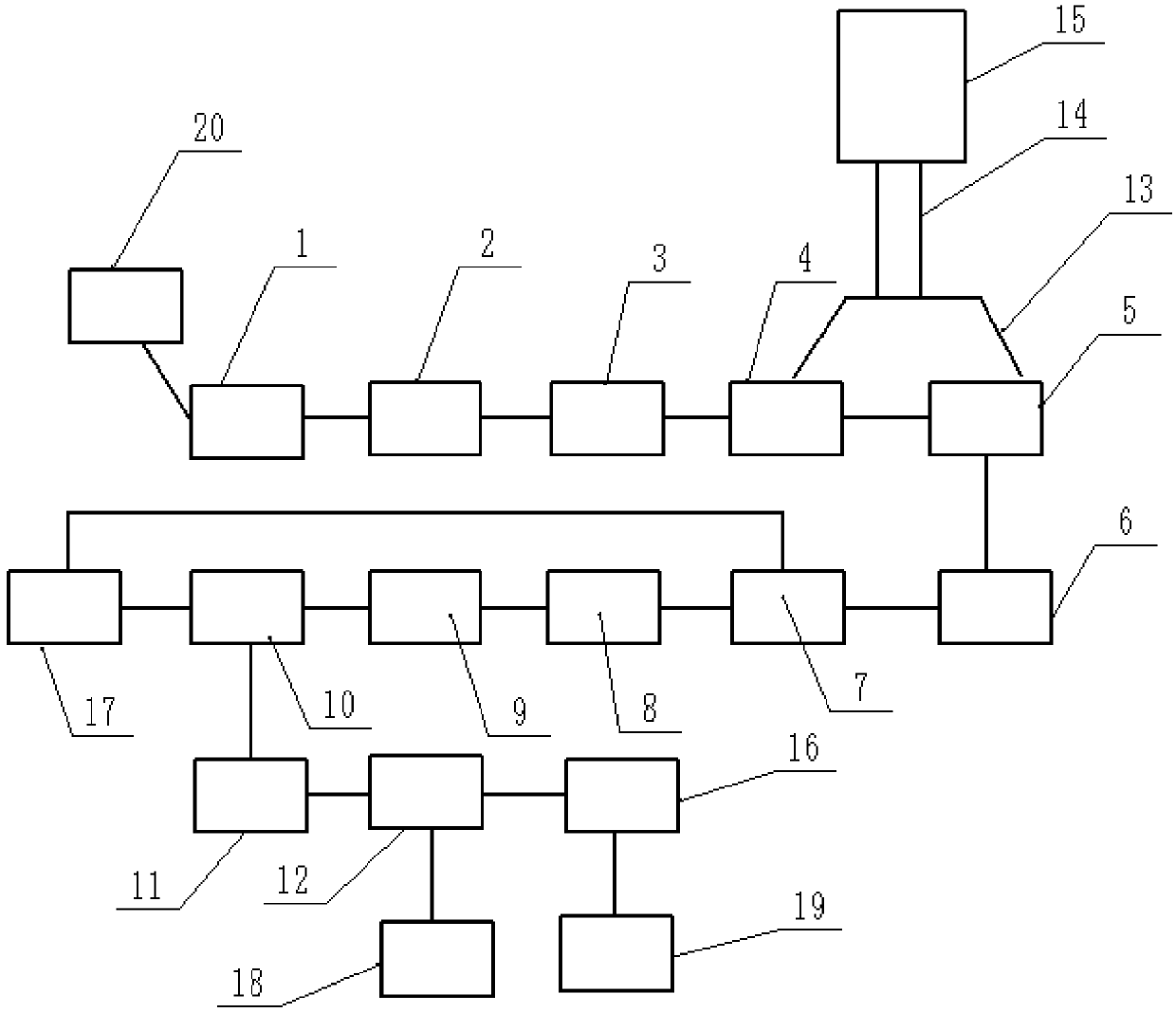

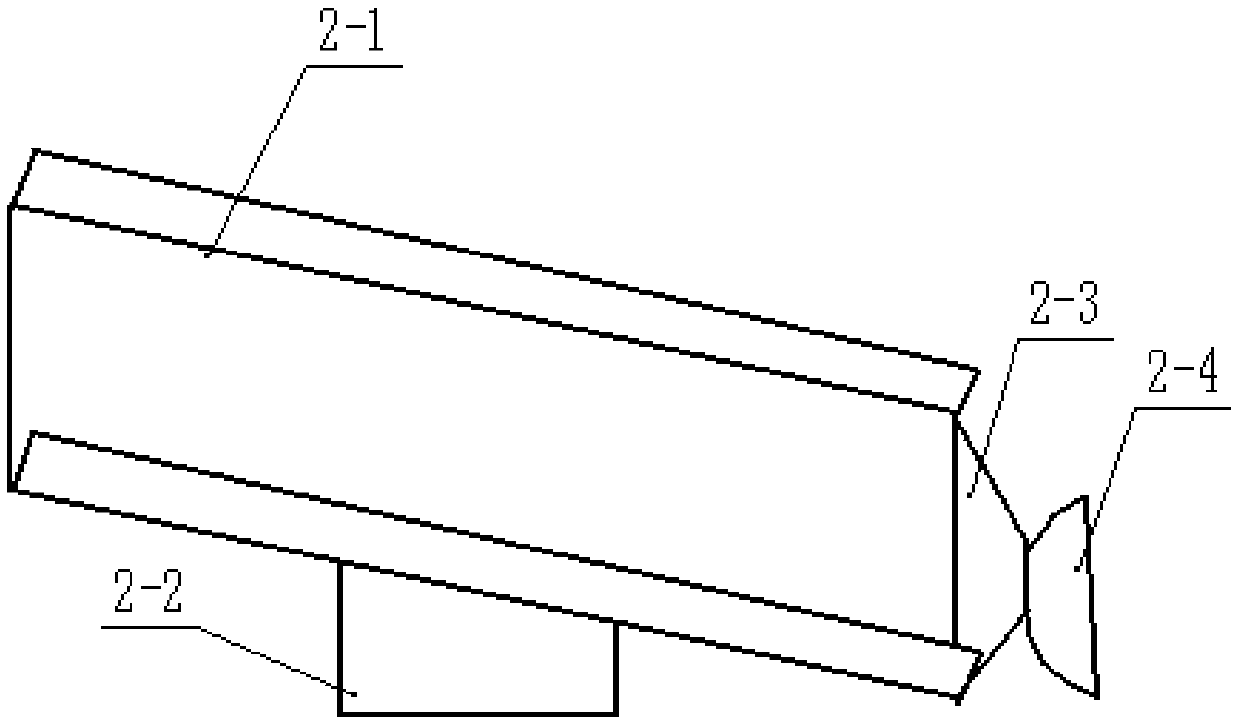

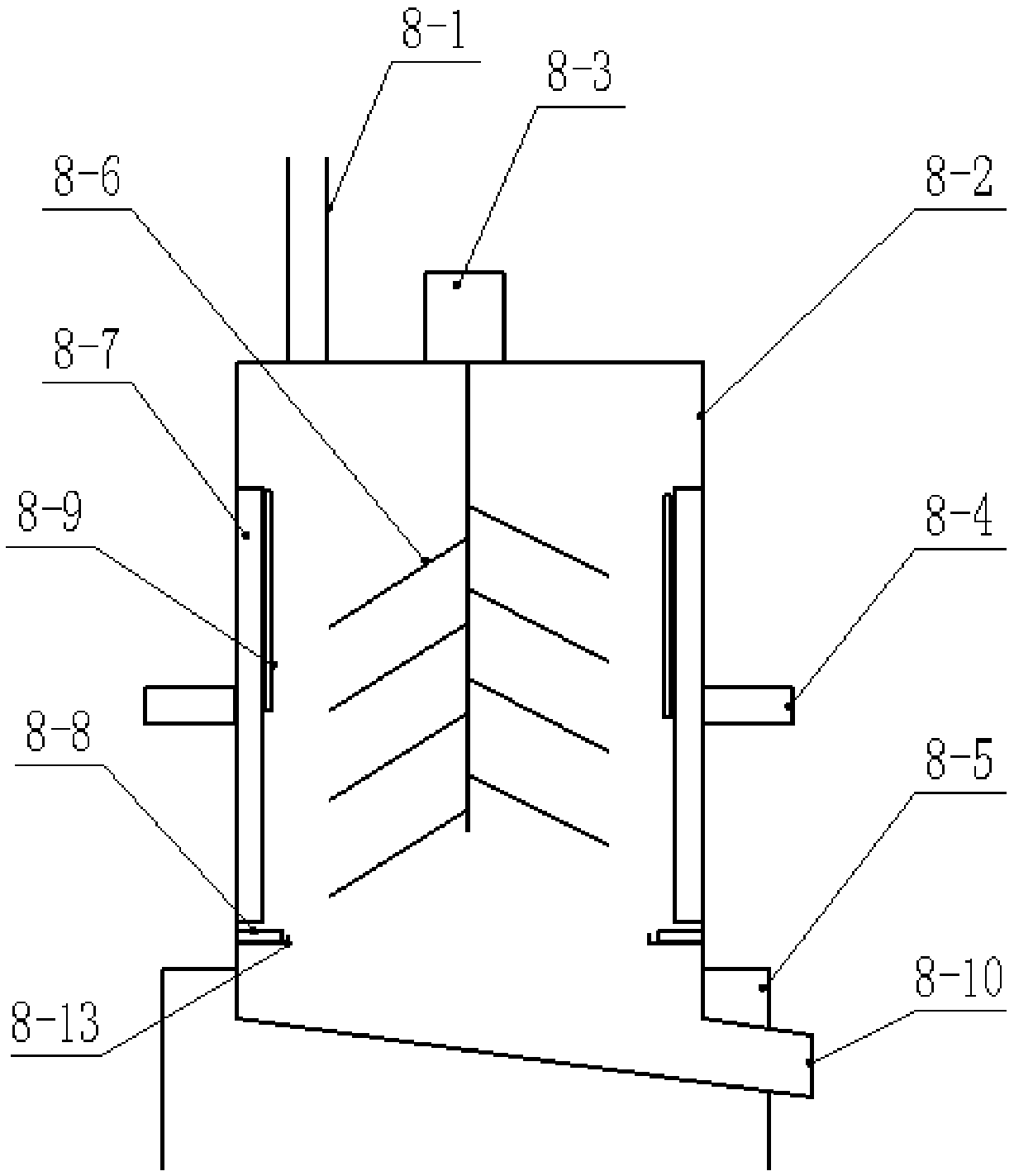

[0032] See figure 1 , a production line of potassium albite feldspar powder, comprising an ore washing part, a crushing part, a grinding part, a screening and impurity removal part, a flotation part, a finished product output part and a gas collection and dust removal part, the ore washing part, the crushing part, the grinding part The powder section, the screening and impurity removal section, the flotation section, and the finished product output section are sequentially connected by a conveyor belt, and the gas-collecting and dust-removing section is connected with the powder-milling section. The ore washing part includes an ore washing machine 20 for washing sludge and the like on the ore. The crushing part includes a jaw crusher 1, a vibrating device 2 and a cone crusher 3, the jaw crusher 1 is connected to the ore washing machine 20 through a conveyor belt, and the vibrating device 2 is connected to the jaw crusher 20. The crusher 1 is connected by a conveyor belt, and ...

Embodiment 2

[0047] In this embodiment, except that the components of the raw materials for making the wear-resistant layer are different, everything else is the same as that in Embodiment 1.

[0048] In this embodiment, the wear-resistant layer is made of raw materials including the following parts by weight: 36 parts of nitrile rubber, 30 parts of epoxy resin, 18 parts of polyvinyl chloride resin, 18 parts of aluminate, 10 parts of aluminum oxide, 8 parts of boron nitride, 8 parts of sodium sulfate, 8 parts of aluminum hydroxide, 6 parts of tungsten carbide and 5 parts of glass fiber.

Embodiment 3

[0050] In this embodiment, except that the components of the raw materials for making the wear-resistant layer are different, everything else is the same as that in Embodiment 1.

[0051] In this embodiment, the wear-resistant layer is made of raw materials including the following parts by weight: 30 parts of nitrile rubber, 25 parts of epoxy resin, 15 parts of polyvinyl chloride resin, 14 parts of aluminate, 8 parts of aluminum oxide, 6 parts of boron nitride, 6 parts of sodium sulfate, 6 parts of aluminum hydroxide, 5 parts of tungsten carbide and 3 parts of glass fiber.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap