Optical glass cleaning agent and preparation method thereof

A technology of optical glass and cleaning agent, which is applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of poor cleaning effect, environmental protection, and residual cleaning liquid, etc., and achieve good cleaning effect, Environmental protection of raw materials and the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

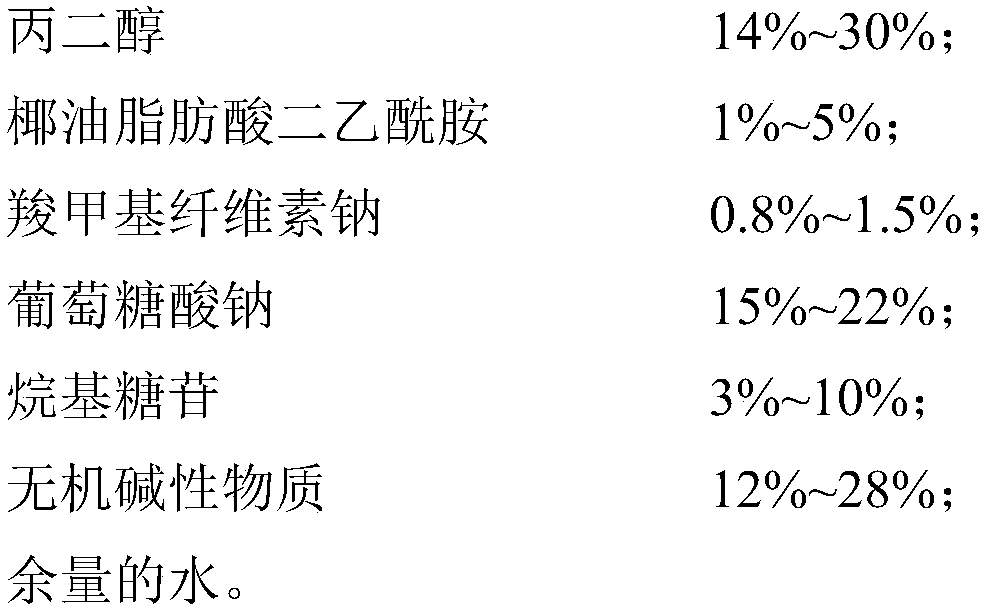

[0040] Embodiment 1, optical glass cleaner

[0041] It is made from the following components in percentage by weight: propylene glycol 20%, coconut oil fatty acid diethylamide 3%, sodium carboxymethylcellulose 1.2%, sodium gluconate 18%, alkyl glycoside (polymerization degree is 1.2~1.8, Alkyl chain length is 10) 3%, sodium hydroxide 18%, deionized water 36.8%.

[0042] Preparation method: first mix propylene glycol, coconut oil fatty acid diethylamide, sodium carboxymethyl cellulose, sodium gluconate, alkyl glucoside, sodium hydroxide and deionized water, heat to 45°C, and turn at 800 rpm Minutes and stir until smooth.

[0043] Factory lens whiteness before cleaning: 2.7, after cleaning lens whiteness: 0.9.

[0044] The cleaning rate of the lens is 92.56%.

[0045] The picture of processing the contaminated lens is as follows figure 1 Shown are pictures placed under two different backgrounds.

[0046] The picture of the lens after cleaning is as follows figure 2 Shown ...

Embodiment 2

[0048] Embodiment 2, optical glass cleaner

[0049] Made from the following components in percentage by weight: propylene glycol 22%, coconut oil fatty acid diethylamide 4%, sodium carboxymethylcellulose 1.2%, sodium gluconate 18%, alkyl glucoside (the degree of polymerization is 1.2~1.8, The alkyl chain length is 12)3%, sodium hydroxide 18%, and deionized water 35.8%.

[0050] Preparation method: first mix propylene glycol, coconut oil fatty acid diethylamide, sodium carboxymethyl cellulose, sodium gluconate, alkyl glucoside, sodium hydroxide and deionized water, heat to 50°C, and rotate at 800 rpm Minutes and stir until smooth.

[0051] Factory lens whiteness before cleaning: 2.4, after cleaning lens whiteness: 0.6.

[0052] The cleaning rate of the lens is 93.42%.

[0053] The contact angle of the optical glass cleaning agent on the surface of the clean lens is 8.34°, indicating that the cleaning agent can wet the lens well and effectively remove the dirt on the surface ...

Embodiment 3

[0054] Embodiment 3, optical glass cleaner

[0055] It is made from the following components in percentage by weight: propylene glycol 22%, coconut oil fatty acid diethylamide 4%, sodium carboxymethylcellulose 1.3%, sodium gluconate 19%, alkyl glycoside (polymerization degree is 1.2~1.8, Alkyl chain length is 12) 5%, sodium hydroxide 18%, deionized water 30.7%.

[0056] Preparation method: first mix propylene glycol, coconut oil fatty acid diethylamide, sodium carboxymethyl cellulose, sodium gluconate, alkyl glucoside, sodium hydroxide and deionized water, heat to 50°C, and rotate at 800 rpm Minutes to stir until smooth.

[0057] Factory lens whiteness before cleaning: 3.1, after cleaning lens whiteness: 1.1.

[0058] The cleaning rate of the lens is 94.28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com