High breakdown voltage ZnO: X thin film and preparation method and application thereof

A technology of high breakdown voltage and thin film, which is applied in the field of high breakdown voltage ZnO:X thin film and its preparation, can solve the problems of high resistivity and breakdown voltage, and achieve the effect of increased film resistivity and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

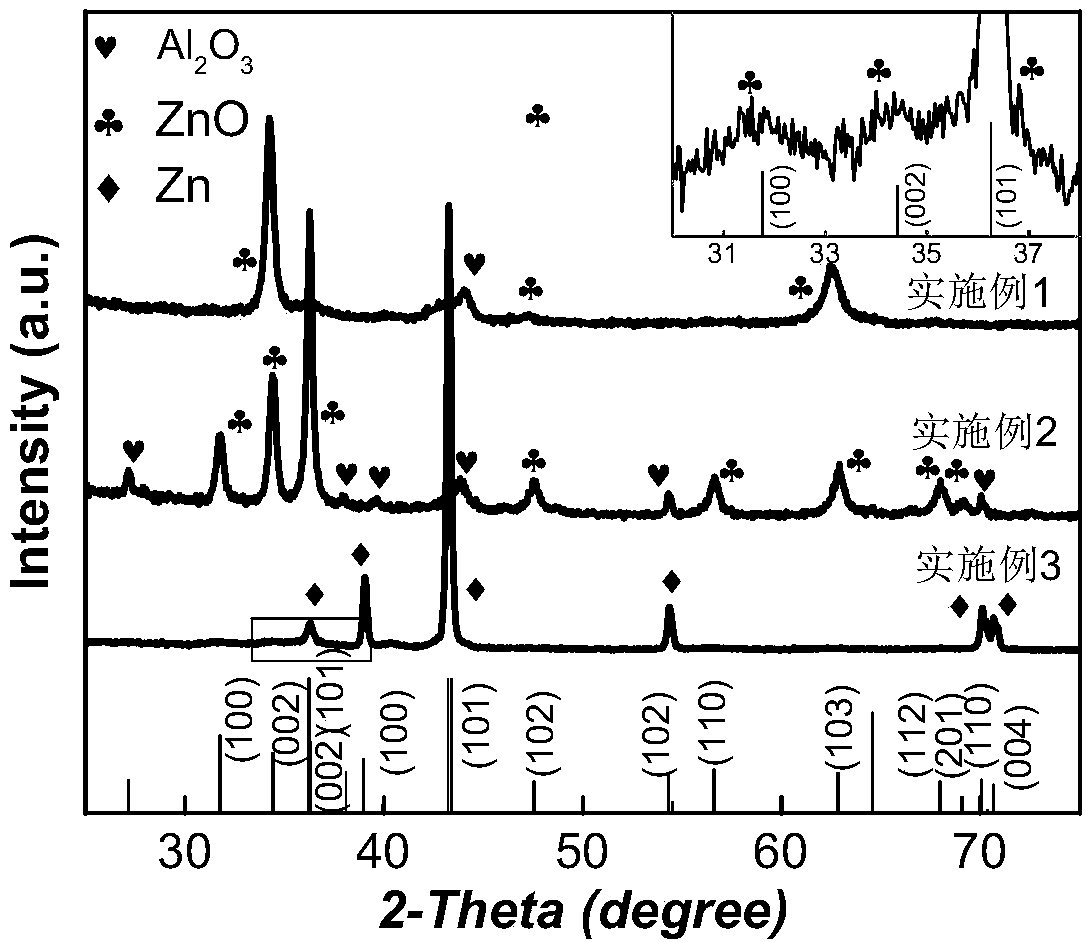

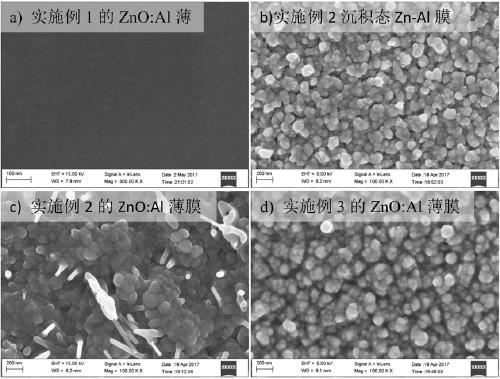

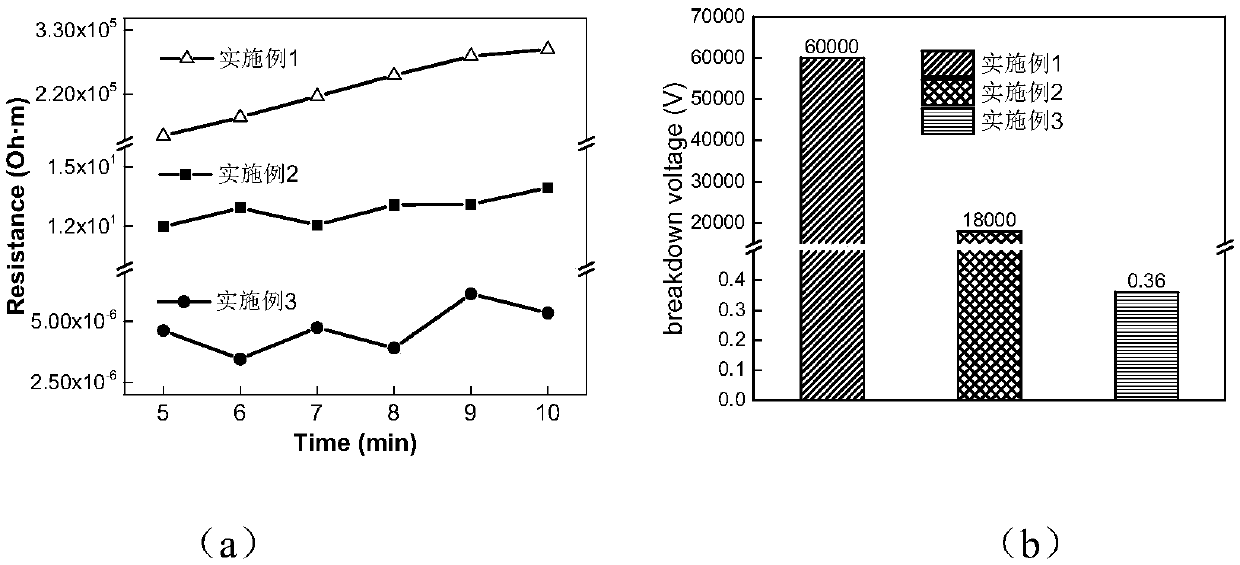

[0056] Example 1 In situ growth of ZnO:Al film

[0057] Step 1, cleaning of substrate

[0058] Use acetone and alcohol to ultrasonically clean the sapphire substrate for 15 minutes. After cleaning, use high-purity inert gas to dry it, put it into the sample chamber, and pass it into the vacuum chamber;

[0059] Step 2, oxophilic treatment of the substrate:

[0060] When the vacuum degree of the vacuum chamber is greater than or equal to 8×10 -5 Pa, the temperature is raised to 600°C, and high-purity O is introduced into the radio frequency plasma activation source. 2 ,, turn on the radio frequency plasma activation source, adjust its power to 400W, the oxygen flow rate to 2.4SCCM, and adjust the vacuum degree of the vacuum chamber to (1.5~4)×10 -3 Pa, oxidative treatment for 10 minutes.

[0061] Step 3, preparation of ZnO:Al film

[0062] The deposition conditions are as follows: the source material with a purity of 99.999% is co-evaporated, the atomic percentage of Al is...

Embodiment 2

[0065] Example 2 Contrast furnace oxidation of ZnO: Al thin film

[0066] Step 1, cleaning of substrate

[0067] Use acetone and alcohol to ultrasonically clean the sapphire substrate for 15 minutes. After cleaning, use high-purity inert gas to dry it, put it into the sample chamber, and pass it into the vacuum chamber;

[0068] Step 2, deposit Zn-Al metal film:

[0069] When the vacuum degree of the vacuum chamber is greater than or equal to 8×10 -5 Pa, use the co-evaporation of Zn and Al source materials with a purity of 99.999%, control the atomic percentage of Al at 14%, and stabilize the working pressure of the vacuum chamber at 1.0×10 when depositing metal. -4 Pa, the deposition time is 100min.

[0070] Step 3, oxidation treatment in vacuum tube furnace

[0071] Oxidation conditions: using high-purity O 2 to oxidize, O 2 The air pressure has been maintained at the atmospheric pressure level, the oxidation temperature is 450°C, and the oxidation time is 180 minutes....

Embodiment 3

[0073] Example 3 Comparison of in-situ oxidation of ZnO: Al film

[0074] Step 1, cleaning of substrate

[0075] Use acetone and alcohol to ultrasonically clean the sapphire substrate for 15 minutes. After cleaning, use high-purity inert gas to dry it, put it into the sample chamber, and pass it into the vacuum chamber;

[0076] Step 2, deposit Zn-Al metal film

[0077] When the vacuum degree of the vacuum chamber is greater than or equal to 8×10 -5 Pa, use the co-evaporation of Zn and Al source materials with a purity of 99.999%, control the atomic percentage of Al at 14%, and stabilize the working pressure of the vacuum chamber at 1.0×10 when depositing metal. -4 Pa, the deposition time is 100min.

[0078] Step 3, in-situ oxidation treatment

[0079] Oxidation conditions are: high-purity O with a flow rate of 1.8 SCCM is introduced into the radio frequency plasma activation source 2 Gas, the working power of the radio frequency plasma activation source is 380W, and the va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com