Preparation method and application of electrostatic self-assembly of graphene/titanium dioxide material

An electrostatic self-assembly, titanium dioxide technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of hydrazine hydrate safety, unfavorable large-scale production, complex production processes, etc. Easy to prepare on a large scale, reducing the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: prepare graphene / titanium dioxide material, the steps are as follows:

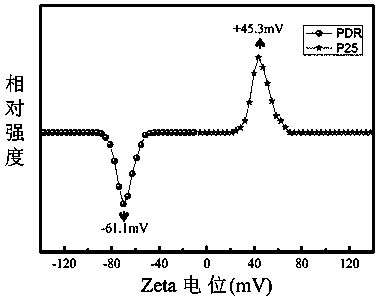

[0034] (1) Add graphene (PDR) with a mass fraction of 0.1% in 100ml deionized water, sonicate for 10 minutes and then stir for 10 minutes, and repeat the process twice before sonicating and then stirring, and finally centrifuge to remove excess dodecylbenzene Sodium sulfonate (SDBS), redisperse the product in 100ml deionized water to obtain a graphene (PDR) dispersion;

[0035] (2) Disperse 2g of titanium dioxide (P25) powder in 50ml of deionized water, add 0.5ml of acetic acid, sonicate for 4 minutes and then stir for 10 minutes. Obtain titanium dioxide (P25) powder;

[0036](3) Add 1 g of titanium dioxide (P25) powder prepared in step (2) to 20 mg of graphene (PDR) dispersion prepared in step (1), stir for 3 hours, centrifuge and freeze-dry to obtain graphene / titanium dioxide in powder form composite materials;

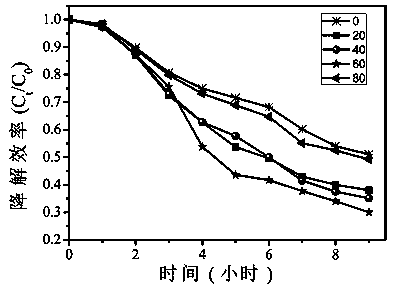

[0037] (4) Take 150 mg of the composite material prepared in step (3...

Embodiment 2

[0039] Embodiment 2: prepare graphene / titanium dioxide material, the steps are as follows:

[0040] (1) Add graphene (PDR) with a mass fraction of 0.1% in 100ml deionized water, stir mechanically to disperse the graphene (PDR) in the water, then add sodium dodecylbenzenesulfonate (SDBS) with a concentration of 20CMC, Sonicate for 10 minutes and then stir for 10 minutes, and repeat the process of ultrasonication and stirring twice, and finally remove excess sodium dodecylbenzenesulfonate (SDBS) by centrifugation, and redisperse the product in 100ml deionized water to obtain graphite olefin (PDR) dispersion;

[0041] (2) Take 2g of titanium dioxide (P25) powder and disperse it in 50ml of deionized water, add 0.5ml of acetic acid, ultrasonicate for 4 minutes and then stir for 10 minutes, and repeat the process twice, after drying in an oven at 60°C to obtain Titanium dioxide (P25) powder;

[0042] (3) Add 1 g of titanium dioxide (P25) powder prepared in step (2) to 20 mg of gra...

Embodiment 3

[0045] Embodiment 3: prepare graphene / titanium dioxide material, the steps are as follows:

[0046] (1) Add graphene (PDR) with a mass fraction of 0.1% in 100ml deionized water, stir mechanically to disperse graphene (PDR) in the water, then add sodium dodecylbenzenesulfonate (SDBS) with a concentration of 40CMC, Sonicate for 10 minutes and then stir for 10 minutes, and repeat the process of ultrasonication and stirring twice, and finally remove excess sodium dodecylbenzenesulfonate (SDBS) by centrifugation, and redisperse the product in 100ml deionized water to obtain graphite olefin (PDR) dispersion;

[0047] (2) Take 2g of titanium dioxide (P25) powder and disperse it in 50ml of deionized water, add 0.5ml of acetic acid, ultrasonicate for 4 minutes and then stir for 10 minutes, and repeat the process twice, after drying in an oven at 60°C to obtain Titanium dioxide (P25) powder;

[0048] (3) Add 1 g of titanium dioxide (P25) powder prepared in step (2) to 20 mg of graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface potential | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com