Preparation method and using method of bromine-oxygen-bismuth photocatalytic composite material for oily sewage treatment

A composite material and sewage treatment technology, which can be applied in the fields of light water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Handling, ease of transfer, effect of prolonged action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: preparation of bismuth oxybromide photocatalytic composite material

[0022] The first step, raw material solution preparation

[0023] Weigh 5g of potassium bromide and 10g of sodium metasilicate respectively, mix them and dissolve them in 1L of water, and record it as solution A; weigh 10g of bismuth nitrate and dissolve it in 1L of a solution with a volume ratio of ethanol:ethylene glycol=1:1, record Make solution B;

[0024] The second step, photocatalytic composite material preparation

[0025] Under stirring conditions, slowly drop solution B into solution A at a rate of 2ml / min. After solution B is completely dripped, let it stand for 12 hours, discard the supernatant, wash the precipitate twice with 5000ml ethanol, and then use Wash twice with 2000ml of water, filter, dry the filter residue at 110°C for 2 hours, grind, and pass through a 300-mesh sieve to obtain a bismuth oxybromide photocatalytic composite material.

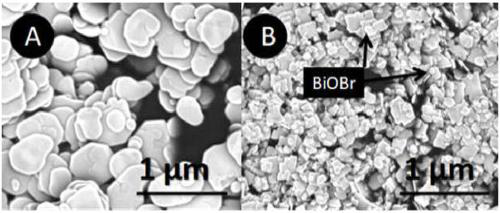

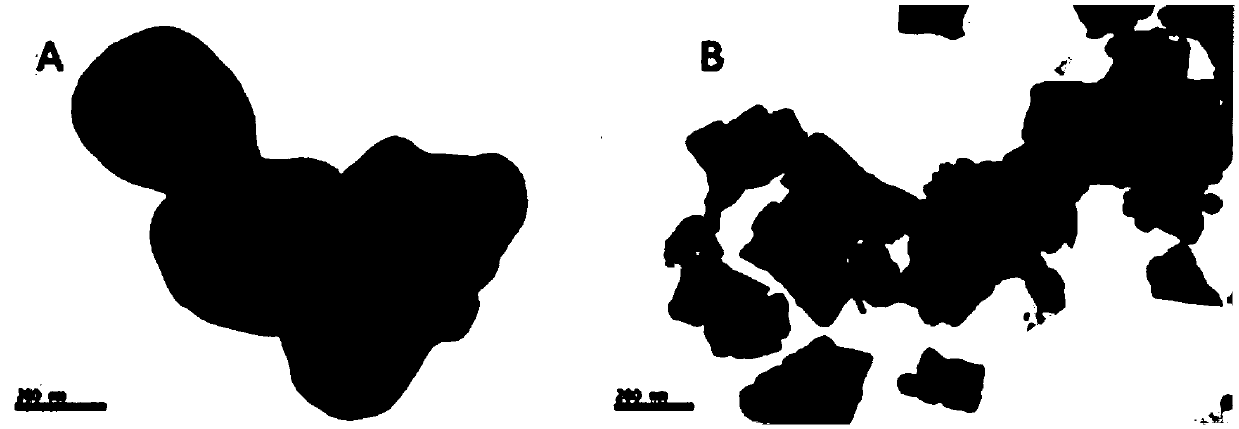

[0026] figure 1 A is the ...

Embodiment 2

[0028] Embodiment 2: preparation of bismuth oxybromide photocatalytic composite material

[0029] The first step, raw material solution preparation

[0030] Weigh 15g potassium bromide and 15g sodium metasilicate respectively, mix and dissolve in 1.5L water, and record it as solution A; weigh 20g bismuth nitrate and dissolve in 1.5L of a solution with a volume ratio of ethanol:ethylene glycol=1:1 , denoted as solution B;

[0031] The second step, photocatalytic composite material preparation

[0032] Under stirring conditions, slowly drop solution B into solution A at a rate of 0.5ml / min. After solution B is completely dripped, let it stand for 15 hours, discard the supernatant, wash the precipitate twice with 1L ethanol, and then Wash twice with 4000ml of water, filter, and dry the filter residue at 105°C for 2 hours, grind, and pass through a 300-mesh sieve to obtain a bismuth oxybromide photocatalytic composite material.

Embodiment 3

[0033] Embodiment 3: preparation of bismuth oxybromide photocatalytic composite material

[0034] The first step, raw material solution preparation

[0035] Weigh 20g potassium bromide and 20g sodium metasilicate respectively, dissolve in 2L water after mixing, and record it as solution A; take 20g bismuth nitrate and dissolve it in the volume ratio of ethanol: ethylene glycol=1: 1 solution 1.5L, Denoted as solution B;

[0036] The second step, photocatalytic composite material preparation

[0037] Under stirring conditions, slowly drop solution B into solution A at a rate of 1ml / min. After solution B is completely dripped, let it stand for 15 hours, discard the supernatant, wash the precipitate twice with 1L ethanol, and then use Wash twice with 4000ml of water, filter, dry the filter residue at 110°C for 2 hours, grind, and pass through a 300-mesh sieve to obtain a bismuth oxybromide photocatalytic composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com