Photocatalytic antibacterial nanofiber membrane for air purification and preparation method thereof

A nanofiber membrane and air purification technology, applied in the field of air purification, can solve the problem of being easily infested by microorganisms such as bacteria, fungi, and molds suspended in the air, reducing the service life of nanofiber membranes, and low photocatalytic activity of bismuth oxyhalide. problems, to achieve the effect of improving photocatalytic activity, improving air purification ability, and improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

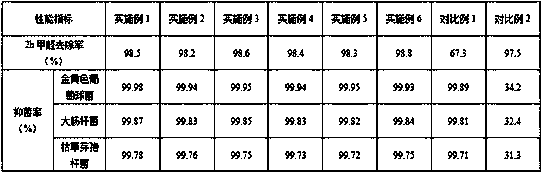

Examples

Embodiment 1

[0033] (1) Add bismuth nitrate pentahydrate into glycerol solvent, slowly add halide salt under stirring, then transfer to hydrothermal reaction kettle for reaction, after cooling, centrifugal precipitation, washing and drying, the ultra-thin Bismuth oxychloride nanosheets; the halide salt is potassium chloride; the temperature of the hydrothermal reaction is 158° C., and the time is 17 hours; the parts by weight of each raw material are 39 parts by weight of bismuth nitrate pentahydrate, 55 parts by weight of glycerol, and the halide salt 6 parts by weight;

[0034] (2) Add the ultra-thin bismuth oxychloride nanosheets and lanthanum chloride prepared in step (1) into deionized water, stir evenly, and then treat with ultrasonic waves at a frequency of 38kHz for 1.5h at room temperature, and then place them at 86°C React in a water bath for 17 hours, centrifuge the product and dry it, place it in a muffle furnace, raise the temperature to 470 ° C for 5 hours, cool and collect i...

Embodiment 2

[0038](1) Add bismuth nitrate pentahydrate into glycerol solvent, slowly add halide salt under stirring, then transfer to hydrothermal reaction kettle for reaction, after cooling, centrifugal precipitation, washing and drying, the ultra-thin Bismuth oxyiodide nanosheets; the halide salt is potassium iodide; the temperature of the hydrothermal reaction is 155° C., and the time is 17 hours; the parts by weight of each raw material are: 38 parts by weight of bismuth nitrate pentahydrate, 56 parts by weight of glycerol, and 6 parts by weight of halide salt share;

[0039] (2) Add the ultra-thin bismuth oxyiodide iodide nanosheets and lanthanum chloride prepared in step (1) into deionized water, stir evenly, and then treat with ultrasonic waves at a frequency of 35kHz for 2 hours at room temperature, and then place them in a water bath at 82°C After reacting in middle temperature for 17.5h, the product was centrifuged and dried, placed in a muffle furnace, heated to 460°C and calci...

Embodiment 3

[0043] (1) Add bismuth nitrate pentahydrate into glycerol solvent, slowly add halide salt under stirring, then transfer to hydrothermal reaction kettle for reaction, after cooling, centrifugal precipitation, washing and drying, the ultra-thin Bismuth oxybromide nanosheets; the halide salt is potassium bromide; the temperature of the hydrothermal reaction is 165° C., and the time is 16 hours; the parts by weight of each raw material are 42 parts by weight of bismuth nitrate pentahydrate, 51 parts by weight of glycerol, and the halide salt 7 parts by weight;

[0044] (2) Add the ultra-thin bismuth oxybromide nanosheets and lanthanum chloride prepared in step (1) into deionized water, stir evenly, and then treat with ultrasonic waves at a frequency of 45kHz for 1h at room temperature, and then place them in a water bath at 88°C The product was reacted for 16.5 hours, and the product was centrifuged and dried, placed in a muffle furnace, heated to 490°C and calcined for 4.5 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com