Aluminum alloy spraying pretreatment method

An aluminum alloy and treatment liquid technology, applied in the direction of pretreatment surface, coating, electrolytic coating, etc., can solve the problems of affecting the combination of aluminum alloy and coating, limited specific surface improvement, poor bonding strength, etc. Detection and control, the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

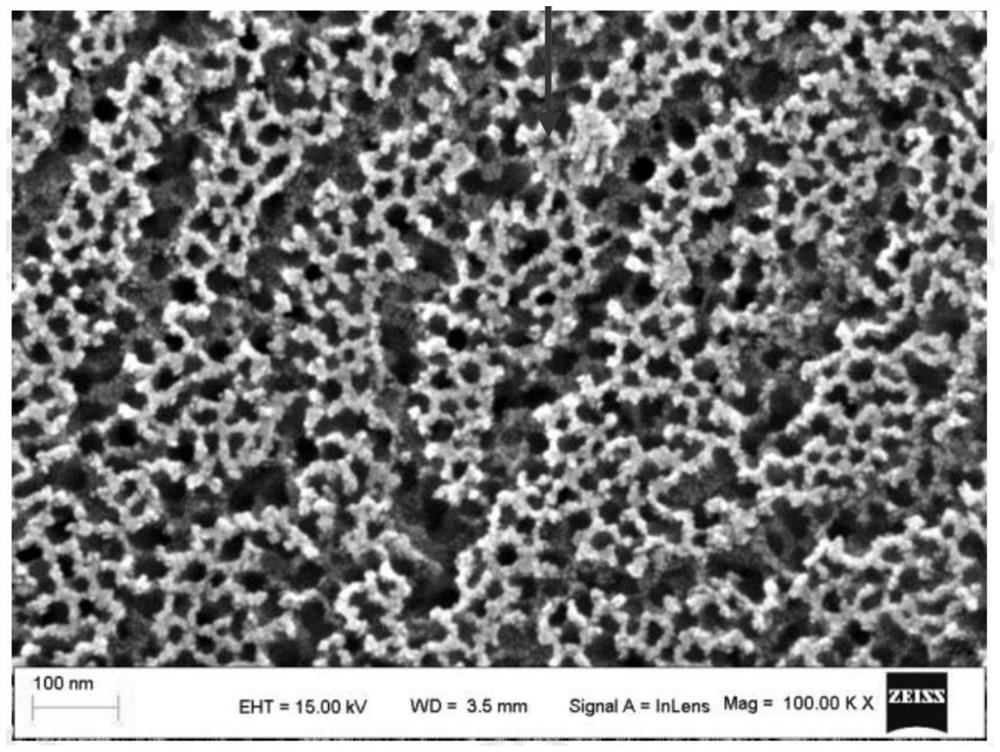

Image

Examples

specific Embodiment

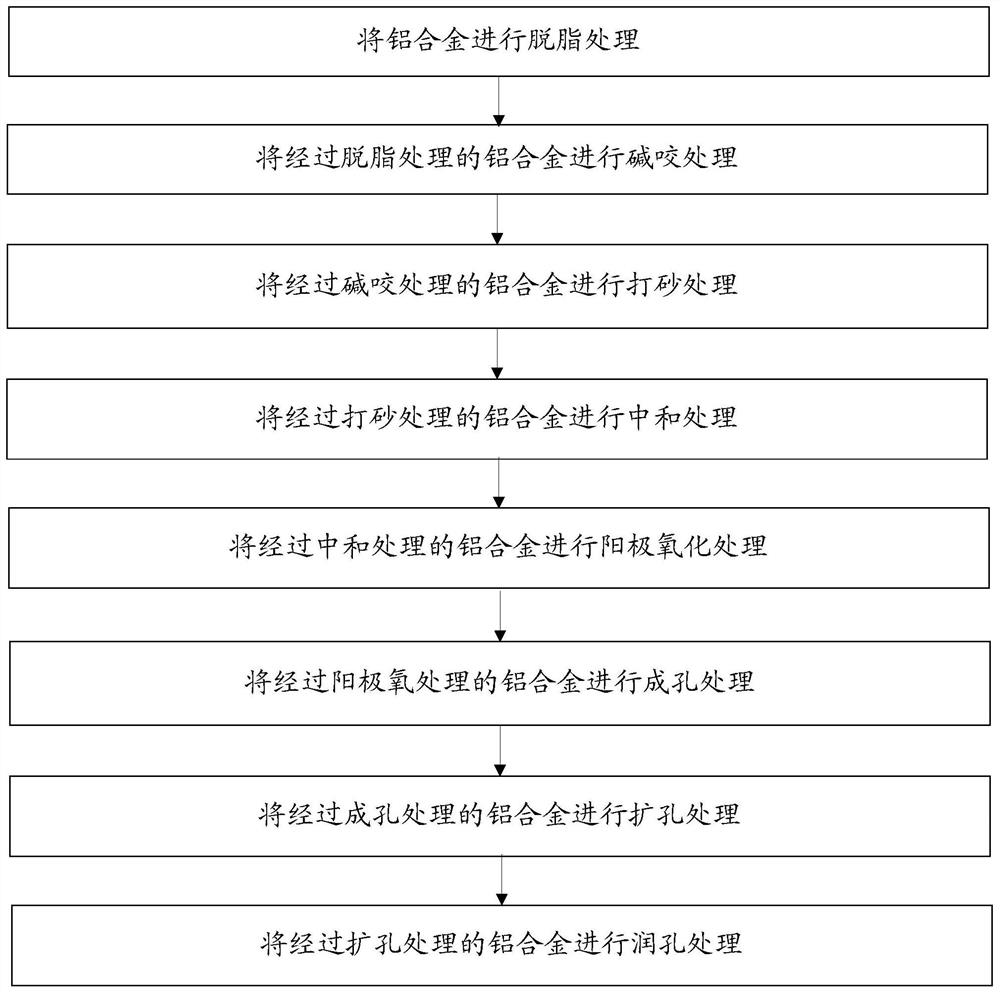

[0103] The experimental aluminum alloy is 7075 aluminum alloy, and the aluminum alloy spraying pretreatment method includes the following steps:

[0104] 1) The aluminum alloy is put into a degreasing agent for degreasing treatment; wherein, the degreasing agent includes the following components: 20 g / L of trisodium phosphate, 8 g / L of sodium carbonate, 6 g / L of sodium hydroxide, 0.5ml of seagull detergent / L and the remainder of the water. The temperature of the degreasing treatment was 62 degrees Celsius and the time was 4 minutes. After three washings, follow-up treatment is carried out.

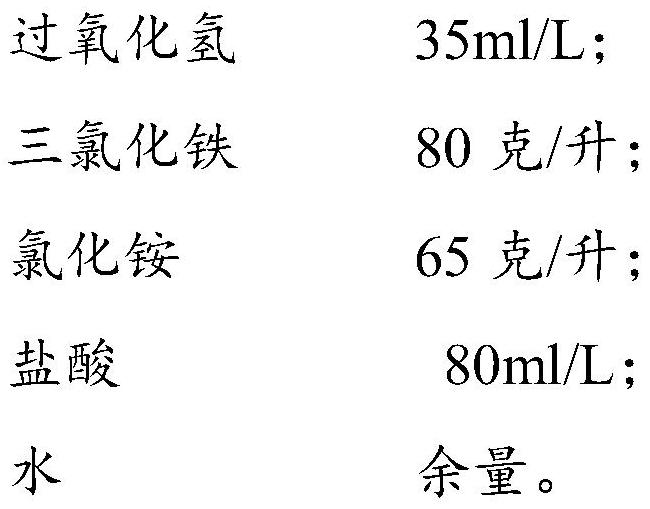

[0105] 2) put the aluminum alloy through the degreasing process into the alkali chelating treatment solution and carry out the alkali chelating treatment; wherein, the alkali chelating treatment solution comprises each component of following mass concentration: sodium hydroxide 18 grams / liter; Isooctyl sodium sulfate 0.1 g / L; water balance. The temperature of the alkali bite treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com