Electromagnetic pulse welding method for aluminium plate and steel plate

A technology of electromagnetic pulse and welding method, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., and can solve the problems of restricting the application of aluminum/steel composite structures, low strength of aluminum/steel welded joints, and the existence of block steel in welded joints, etc. problem, to achieve the effect of avoiding contact, improving performance, and negative temperature coefficient of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

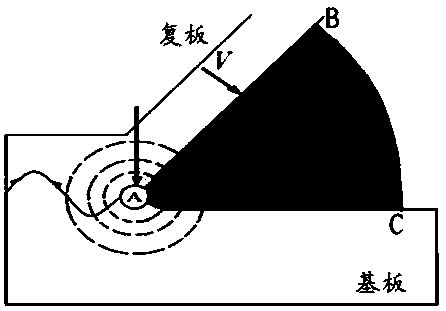

[0038] The dimensions of aluminum plate and stainless steel plate are both 20mm×100mm×2mm. The specific steps of electromagnetic pulse welding are as follows:

[0039] (1) Use sandpaper to polish off the oil on the surface of the aluminum plate, scrub it with acetone and dry it, coat the surface of the aluminum plate with zirconia solution, mark the specific position of spraying zirconia on the aluminum plate, and use absolute ethanol to prepare the zirconia powder Form a zirconia solution with a concentration of 40%. Use a 5mL dropper to absorb the zirconia solution, then pour it into a 10ml watering can, choose a place 10-20mm away from the doubler board horizontally, and use a watering can to evenly spray a layer of zirconia solution (5ml solution has just been used up), and then dried at room temperature, the effect of the aluminum plate after spraying the zirconia solution after drying is shown in image 3 As shown, the white part is the coated zirconia, the length × widt...

Embodiment 2

[0045] The dimensions of aluminum plate and stainless steel plate are both 20mm×100mm×2mm. The specific steps of electromagnetic pulse welding are as follows:

[0046] (1) Use sandpaper to polish off the oil on the surface of the aluminum plate, scrub it with acetone and dry it, then coat the surface of the aluminum plate with zirconia powder, mark the specific position of spraying zirconia on the aluminum plate, and use absolute ethanol to configure the zirconia into Zirconia solution, the concentration is 30%, use a 10ml dropper to absorb the zirconia solution, then pour it into a 10ml watering can, choose a place 10-20mm away from the doubler board horizontally, and spray it evenly on the mark on the upper surface of the doubler board layer of zirconia solution (10ml solution is just used up), and then dry at room temperature.

[0047] (2) Place the aluminum plate and steel plate to be welded on the welding fixture with the aluminum plate as the double plate and the steel p...

Embodiment 3

[0055] The dimensions of aluminum plate and stainless steel plate are both 20mm×100mm×2mm. The specific steps of electromagnetic pulse welding are as follows:

[0056] (1) Use sandpaper to polish off the oil on the surface of the aluminum plate, scrub it with acetone and dry it, then coat the surface of the aluminum plate with zirconia powder, mark the specific position of spraying zirconia on the aluminum plate, and use absolute ethanol to configure the zirconia into The concentration of zirconia solution is 35%. Accurately measure 8mL of zirconia solution, pour it into a 10ml watering can, choose a place 10-20mm away from the doubler board horizontally, and spray a layer of zirconia evenly on the mark on the upper surface of the doubler board with a watering can. Zirconium solution (8ml solution is just used up), and then dry at room temperature.

[0057] (2) Place the aluminum plate and steel plate to be welded on the welding fixture with the aluminum plate as the double pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com