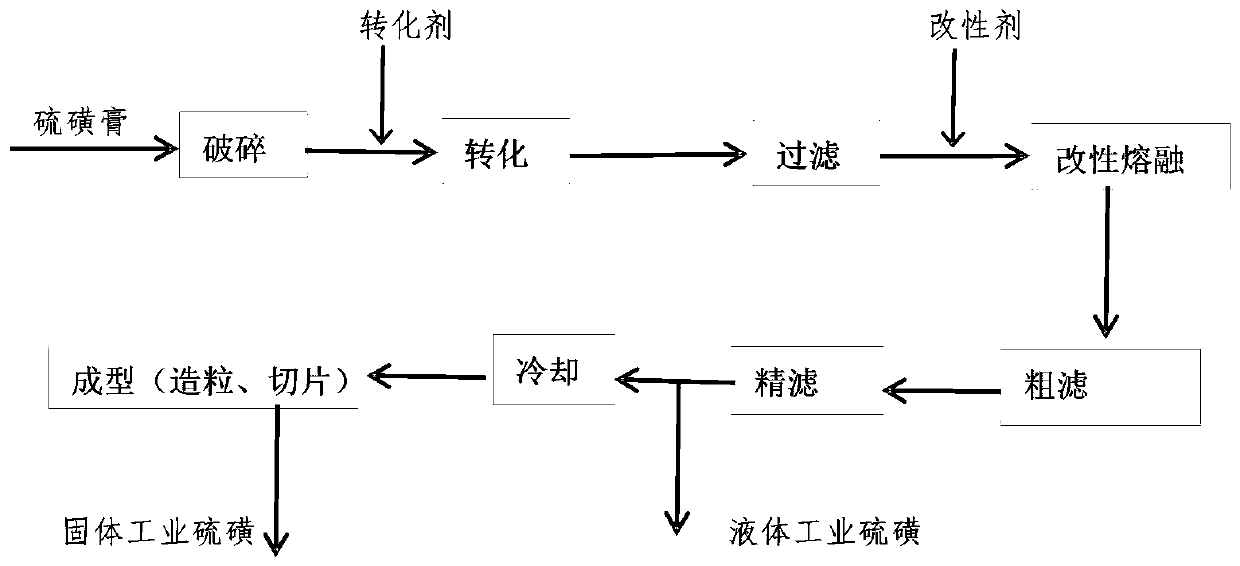

Process method for refining industrial sulfur from crude sulfur

A process method and sulfur technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of low sulfur recovery rate, environmental pollution, substandard product quality, etc., and achieve high sulfur recovery rate and broad market prospects. , to achieve the effect of comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 100kg of sulfur paste with a sulfur content of 65% is first pretreated to make coarse sulfur powder with a water content of 2% and a particle size of <2mm;

[0027] (2) Put the crude sulfur paste powder prepared in step (1) into the conversion tank, add 140kg of 98% concentrated sulfuric acid, and react for 1.5 hours at a controlled temperature of 125°C with stirring to remove the organic sulfur in the crude sulfur. After removing impurities and a small amount of impurities such as ammonium thiocyanate and ammonium sulfate, conversion slurry is obtained;

[0028] (3) Vacuum filter the conversion slurry in step (2) to obtain 68.8 kg of crude sulfur filter cake and filter mother liquor;

[0029] (4) Add the crude sulfur filter cake in the step (3) into the molten sulfur kettle, add 5kg of calcium carbonate powder, 0.32kg of silica bath soil and 2.8kg of gypsum powder, and heat the crude sulfur to melt into crude liquid sulfur;

[0030] (5) After the crude liquid sulf...

Embodiment 2

[0033] (1) 100kg of sulfur paste with a sulfur content of 95% is first pretreated to make coarse sulfur powder with a water content of 2% and a particle size of <2mm;

[0034] (2) Put the crude sulfur paste powder prepared in step (1) into the conversion tank, add 120kg of 98% concentrated sulfuric acid, and react for 1.2 hours at a controlled temperature of 120°C with stirring to remove the organic sulfur in the crude sulfur. After removing impurities and a small amount of impurities such as ammonium thiocyanate and ammonium sulfate, conversion slurry is obtained;

[0035] (3) Vacuum filter the conversion slurry in step (2) to obtain 96.4 kg of crude sulfur filter cake and filter mother liquor;

[0036] (4) Add the crude sulfur filter cake in the step (3) into the melting sulfur kettle, add 3.5kg of calcium carbonate powder, 0.3kg of silicon bath soil and 3.1kg of gypsum powder, and heat the crude sulfur to melt into crude liquid sulfur;

[0037] (5) After the crude liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com