High-efficiency power generation and denitrification method of microbial fuel cell with a high-salt and nitrogen-containing wastewater matrix

A fuel cell and microbial technology, applied in chemical instruments and methods, biological water/sewage treatment, electrochemical-biological combination treatment, etc., can solve problems such as increased operating costs, no application value, and poor stability of microbial activity in salt-tolerant electrodes. To achieve the effect of improving denitrification ability, strengthening denitrification ability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1. Inhibition of high-salt substrates on microbial fuel cell electricity production

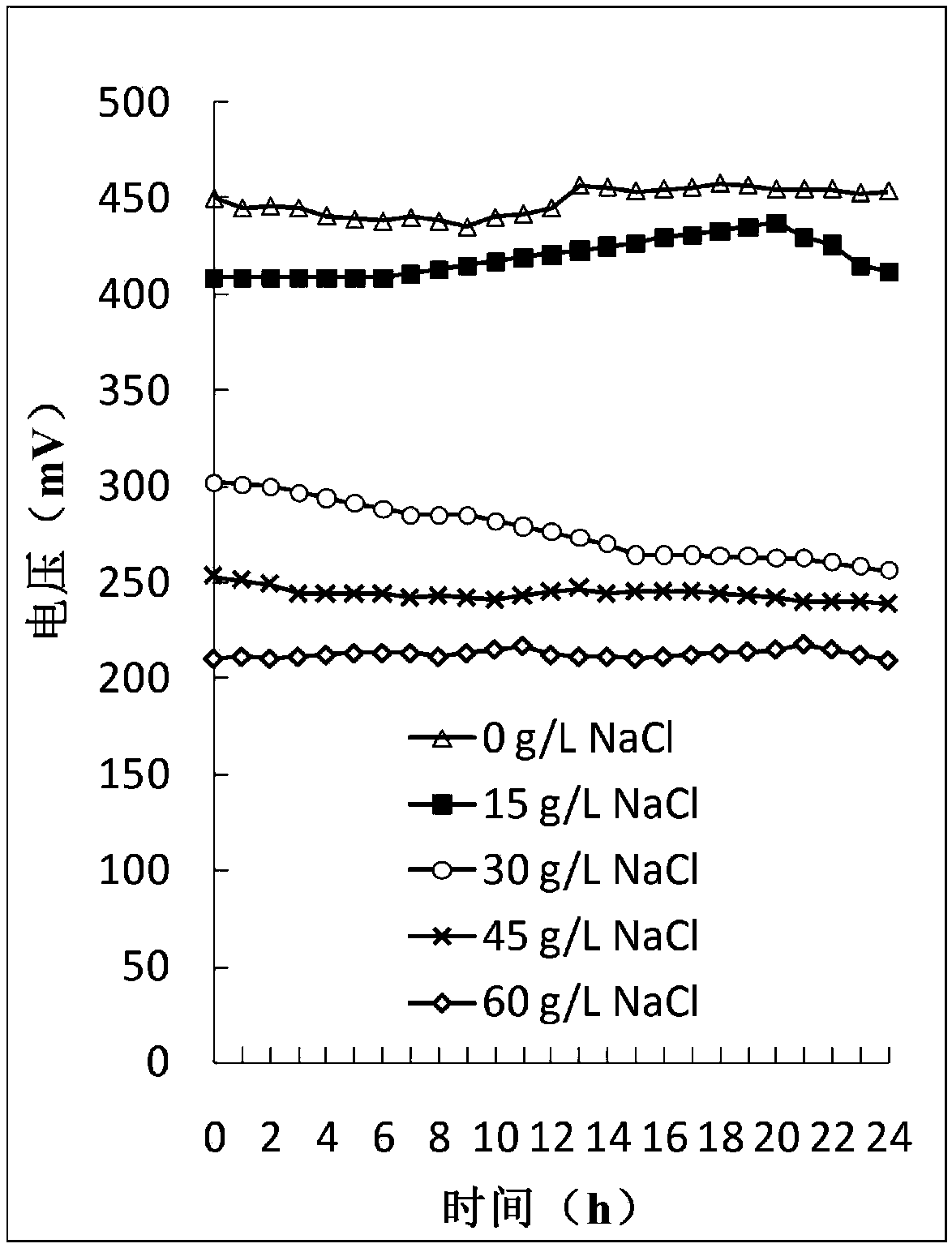

[0042] Take 5 bipolar single-chamber MFCs that operate stably in 0g / L NaCl MFC matrix, set the NaCl concentration of the MFC matrix to 0, 15, 30, 45, 60g / L, respectively, and culture them in a 30°C incubator. Use the DT9205L multimeter to measure the voltage every 1h. Three parallel experimental samples were set up for each same experiment. The same below.

[0043] Inhibition of high-salt substrates on power generation by microbial fuel cells figure 1 . figure 1 It was shown that as the NaCl concentration in the MFC matrix increased, the voltage of the MFC also gradually decreased. When the NaCl concentration increased from 0g / L to 15, 30, 45, and 60g / L, the average voltage within 24 hours decreased by 10.1%, 35.6%, 43.1%, and 54.5%, respectively. The results showed that the high-salt substrate had a significant inhibitory effect on the electricity production of the microb...

Embodiment 2

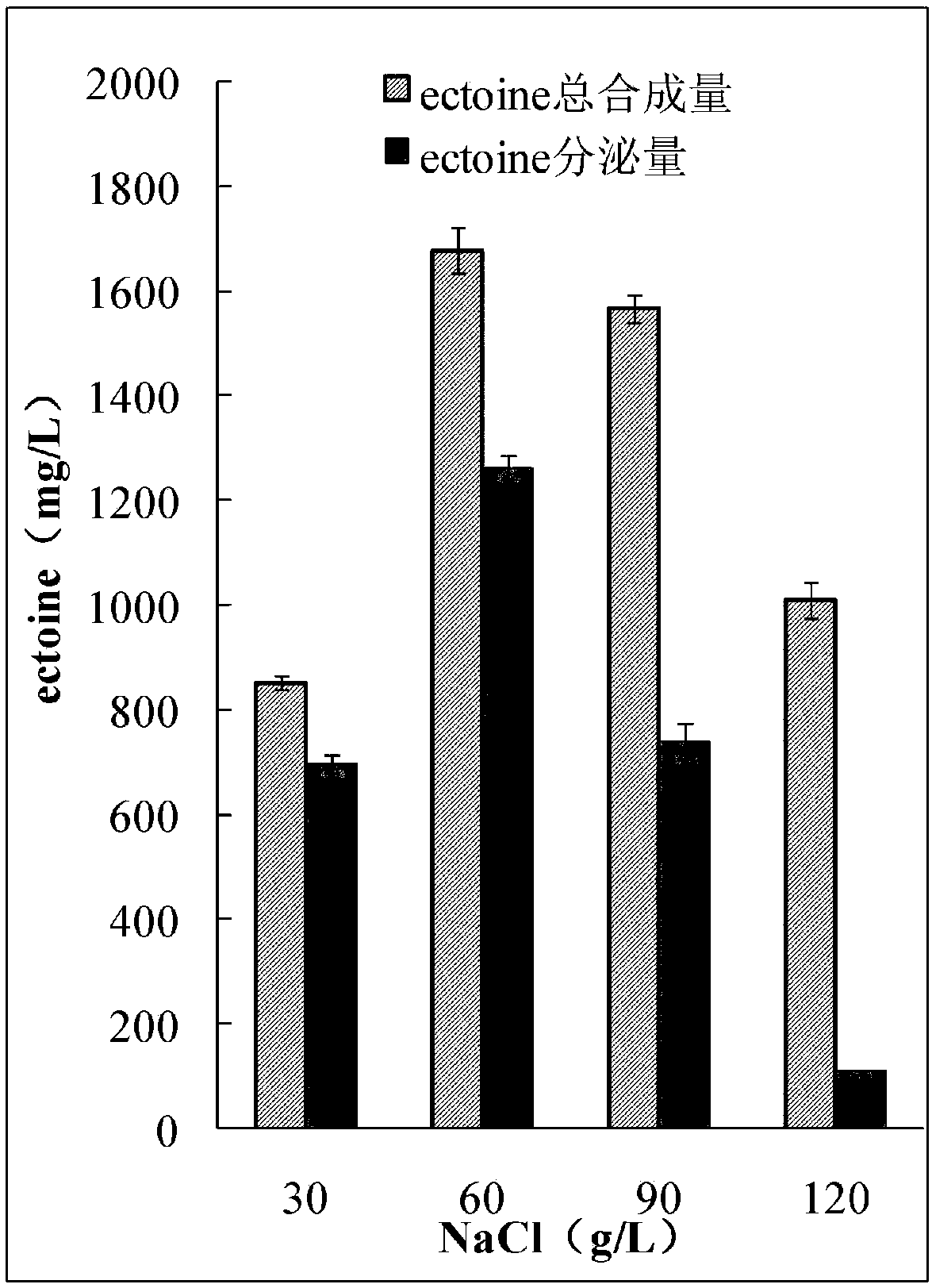

[0044] Example 2.H.alkaliphila DSM 16354 synthesizes and secretes ectoine

[0045] Ectoine concentration determination method. Determination of extracellular ectoine concentration: ectoine-induced synthetic culture medium was centrifuged at 14000×g, and the supernatant was diluted 10 times with distilled water for HPLC determination (ectoine secreted by cells). Determination of intracellular ectoine concentration: Centrifuge according to the above method, collect the precipitated cells, wash with NaCl-Kpi buffer solution (100mM, pH7.2, the concentration of NaCl is the same as that of the medium), and add the same volume of culture medium to the centrifuged precipitate Extracted with 80% ethanol (v / v), resuspended, and left at room temperature overnight. The suspension was centrifuged again, and the supernatant was taken for HPLC analysis (for intracellular ectoine). The total concentration of ectoine is the sum of extracellular and intracellular ectoine concentrations. The ...

Embodiment 3

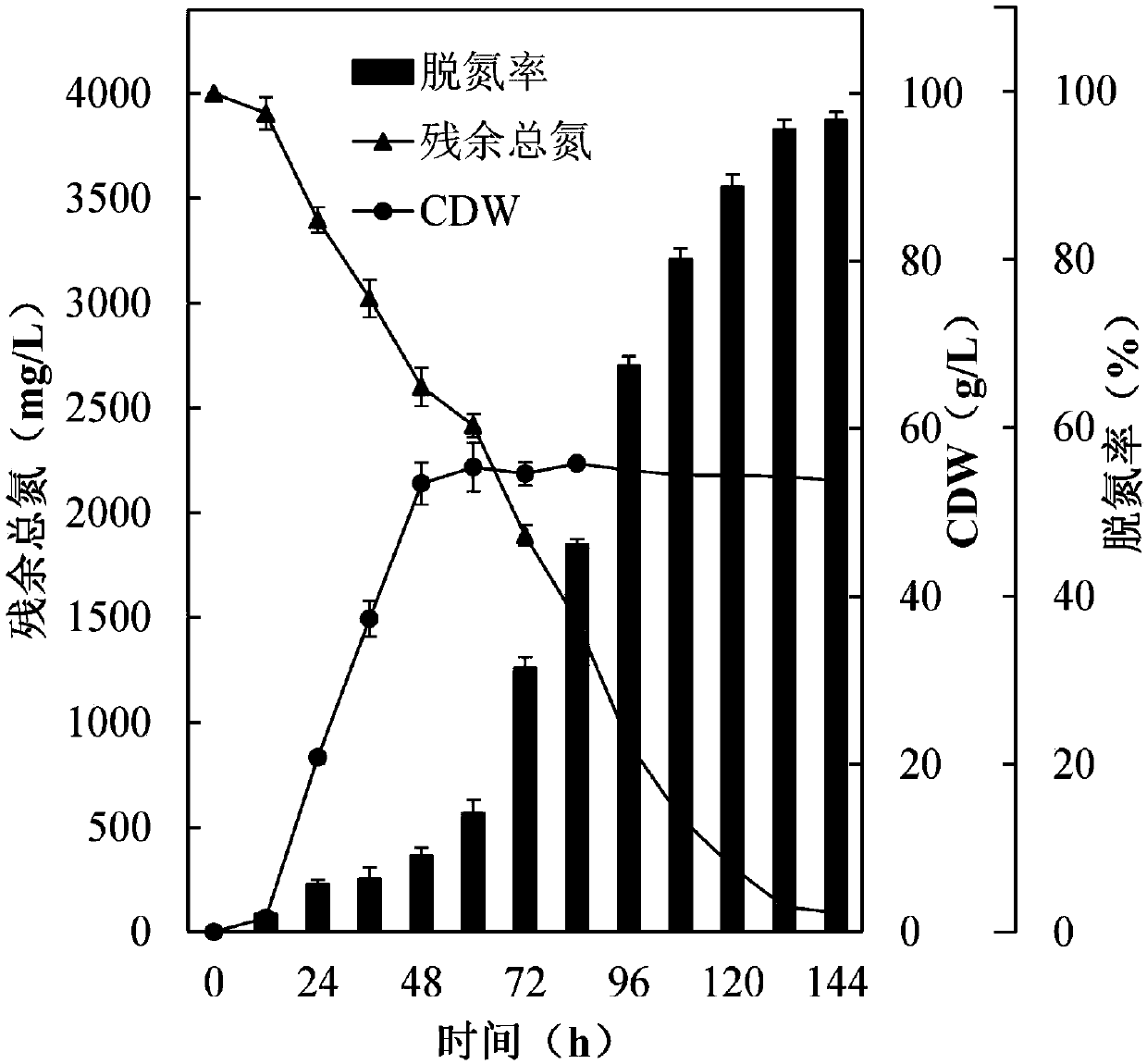

[0047] Example 3. H. alkaliphila DSM 16354 SND denitrification

[0048] Total inorganic nitrogen (TN) including ammoniacal nitrogen Nitrite nitrogen Nitrate nitrogen The denitrification rate is defined as the percentage of the reduced TN in the denitrification system to the initial TN. Nitrogen removal rate = (TN 0 -CN-TN t ) / (TN 0 -CN) × 100%. where NT 0 TN is the initial denitrification, CN is the total nitrogen of the cell, TN t is the TN at a certain moment in the denitrification process. Determination by Nessler's reagent method concentration. Determination of diazo-azo method Determination of concentration zinc cadmium reduction method concentration. Cellular total nitrogen (CN) concentration was determined by Kjeldahl method to determine CN. The CDW with different masses was used to measure CN, and the relational expression between CDW and CN was fitted. In the experiment, CN is calculated by measuring CDW.

[0049] 5mL LB (60g / L NaCl) medium, 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com