High-precision manufacturing process of a mobile phone metal sign

A production process and high-precision technology, applied in coatings, electrolytic coatings, electrophoretic plating, etc., can solve the problems of insufficient precision, poor corrosion resistance, easy to fall off, etc., to increase precision, avoid precision deterioration, paint layer consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

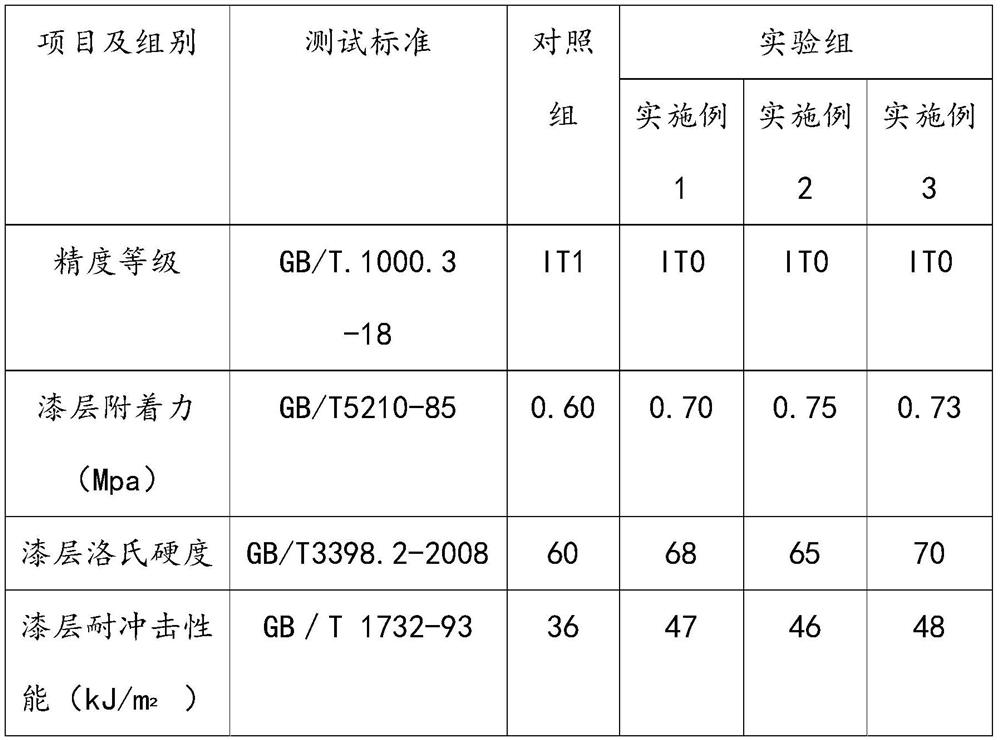

Examples

Embodiment 1

[0019] A high-precision manufacturing process for mobile phone metal signs, comprising the following steps:

[0020] 1) First polish the metal plate with sandpaper to remove the oxide film on the surface, then prepare a degreasing solution with acetone, alcohol, trichlorethylene, sodium carbonate and sodium phosphate in a ratio of 1:1:1:1:1 by weight, The degreasing solution was heated to 45°C by heating in a water bath, and then the polished metal plate was put into the degreasing solution for degreasing. The degreasing time was 16 minutes. Finally, the degreasing treated metal plate was rinsed with deionized water and dried;

[0021] 2) First mix polyvinyl alcohol cinnamate, phthalocyanine, n-butanol, polyethylene glycol and deionized water in parts by weight: 80 parts of polyvinyl alcohol cinnamate, 30 parts of phthalocyanine, 30 parts of n-butanol 100 parts, 100 parts of polyethylene glycol and 100 parts of deionized water are configured into a liquid photosensitive adhesi...

Embodiment 2

[0028] A high-precision manufacturing process for mobile phone metal signs, comprising the following steps:

[0029] 1) First, sand the metal plate with sandpaper to remove the oxide film on the surface, then prepare a degreasing solution with acetone, alcohol, trichlorethylene, sodium carbonate and sodium phosphate in a ratio of 2:1:1:1:1 by weight, The degreasing solution is heated to 35°C by heating in a water bath, and then the polished metal plate is put into the degreasing solution for degreasing. The degreasing time is 10 minutes. Finally, the degreased metal plate is rinsed with deionized water and dried;

[0030] 2) First mix polyvinyl alcohol cinnamate, phthalocyanine, n-butanol, polyethylene glycol and deionized water in parts by weight: 60 parts of polyvinyl alcohol cinnamate, 40 parts of phthalocyanine, 50 parts of n-butanol 160 parts of polyethylene glycol and 140 parts of deionized water are configured into a liquid photosensitive adhesive, and then the metal pl...

Embodiment 3

[0037] A high-precision manufacturing process for mobile phone metal signs, comprising the following steps:

[0038] 1) First, sand the metal plate with sandpaper to remove the oxide film on the surface, then prepare a degreasing solution with acetone, alcohol, trichlorethylene, sodium carbonate and sodium phosphate in a ratio of 1:2:1:1:1 by weight, The degreasing solution is heated to 40°C by heating in a water bath, and then the polished metal plate is put into the degreasing solution for degreasing. The degreasing time is 13 minutes. Finally, the degreasing treated metal plate is rinsed with deionized water and dried;

[0039] 2) First mix polyvinyl alcohol cinnamate, phthalocyanine, n-butanol, polyethylene glycol and deionized water in parts by weight: 70 parts of polyvinyl alcohol cinnamate, 35 parts of phthalocyanine, 40 parts of n-butanol 130 parts, 130 parts of polyethylene glycol and 120 parts of deionized water are configured into liquid photosensitive glue, then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com