Amino acid polypeptide feed and preparation method thereof

A polypeptide feed and amino acid technology, applied in animal feed, animal feed, applications, etc., can solve the problems of high-pressure damage and denaturation of protein, high energy consumption, etc., and achieve the effects of helping growth, high protein nitrogen content, and high protein nitrogen recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

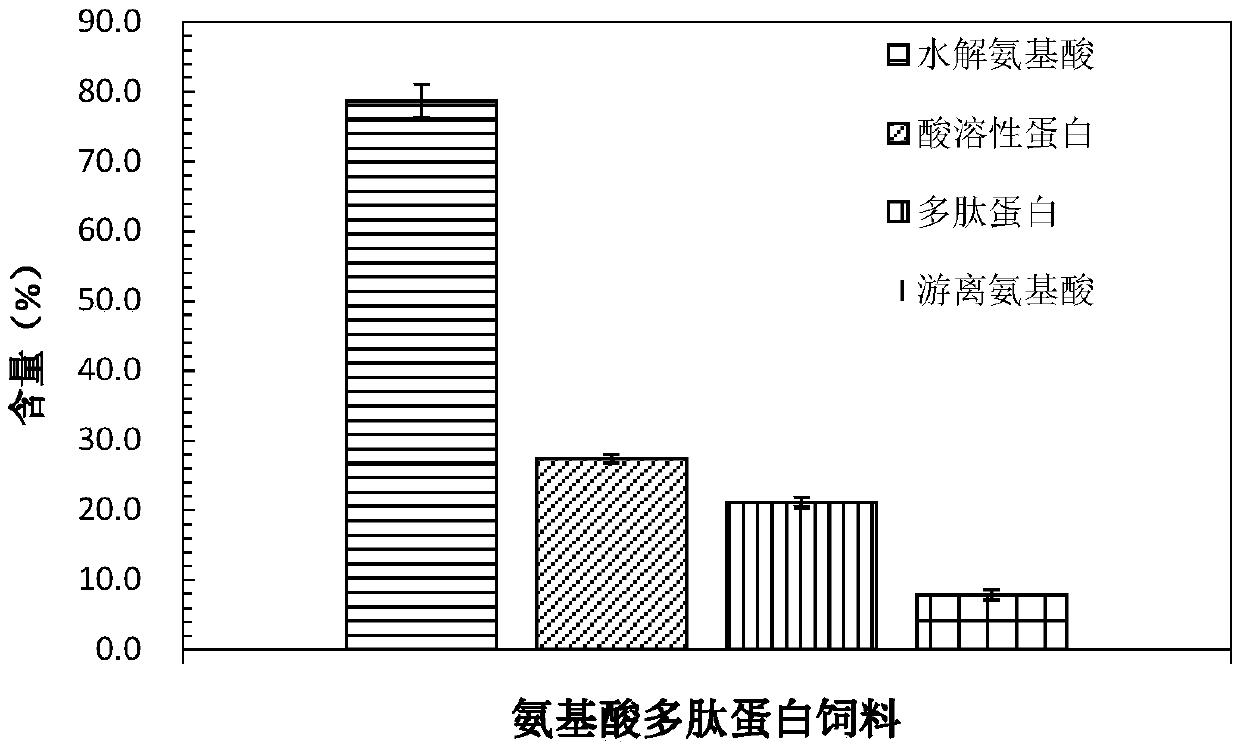

[0034] The anaerobic keratin-degrading bacteria 18D-TA was cultivated to obtain the fermented seed liquid; the feather and the fermented seed liquid were mixed according to the mass / volume ratio of 1:1; cultivated at 55°C for 20h; kept at 85°C for 4h; added bran 10% is prepared into amino acid polypeptide feed. After testing, the feed is rich in free amino acids, polypeptide proteins, organic acids and other nutritional components required by animals. Among them, the content of hydrolyzed amino acids is 76.9-80.3%, the content of acid-soluble proteins is 26.9-27.8%, and the content of polypeptide proteins is 20.6-21.6%. , free amino acid content 7.4-8.4% ( figure 1 ).

Embodiment 2

[0036] Cultivate anaerobic keratin-degrading bacteria 18D-TA to obtain fermented seed liquid; mix feather and fermented seed liquid at a volume ratio of 1:5; culture at 55°C for 16 hours; keep warm at 85°C for 3 hours; add 5% corn flour , 5% of bran is prepared into amino acid polypeptide protein feed. After testing, the protein feed contains 76% of hydrolyzed amino acid, 16% of acid-soluble protein, 13% of polypeptide protein, 5% of free amino acid, and protein digestibility of 75%.

Embodiment 3

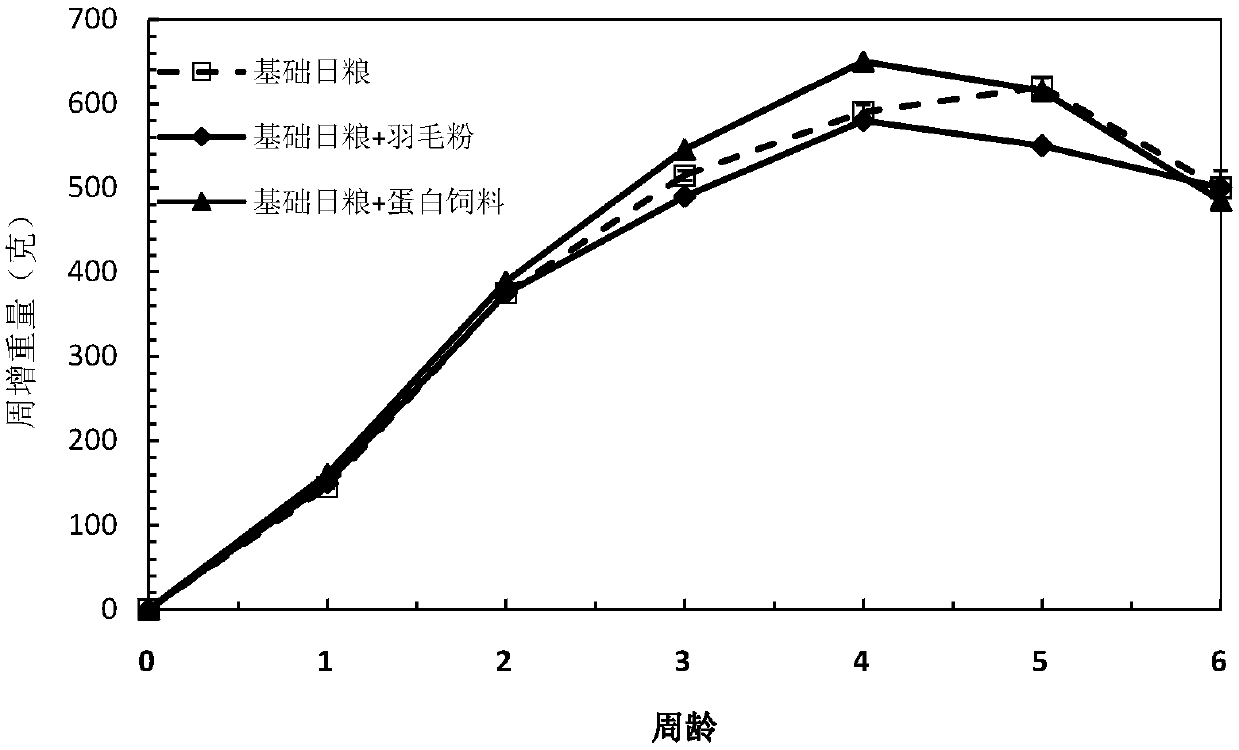

[0038] In this embodiment, the meat ducks at the age of 0 weeks, body weight and physical condition are basically the same with the feed obtained in the present invention. The feeding method is as follows: the control group is fed with a conventional corn soybean meal basal ration, and the experimental group is replaced by the feed obtained in the present invention by 30%. The basal diet, 20 per group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com