Method for preparing composite sponge capable of absorbing viscous crude oil

A composite sponge and crude oil technology, applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc., can solve problems such as easy failure, safety hazards, etc., and achieve low cost, easy operation, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

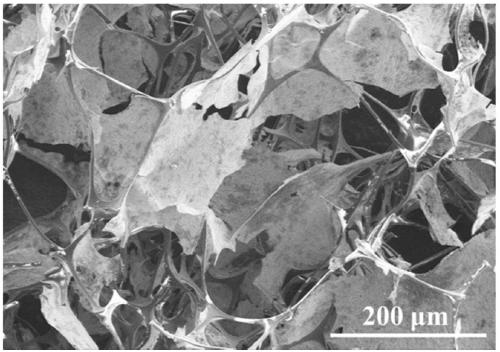

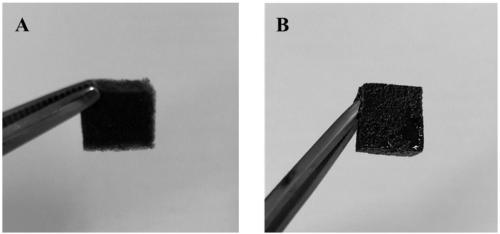

[0033] (1) Add 90 mg of graphene oxide powder to 30 ml of pure water, and use an ultrasonic cell disruptor at 300W for 10 minutes of ultrasound to prepare a 3 mg / ml graphene oxide stock solution;

[0034] (2) Take 4.667ml graphene oxide stock solution, add 9.305ml pure water, 28μL ammonia water and 12.3mg L-ascorbic acid;

[0035] (3) Put the melamine sponge and the above solution into a 20ml hydrothermal reaction kettle for hydrothermal reaction, the hydrothermal reaction temperature is 95°C, and the time is 60min;

[0036] (4) Take out the reacted sponge and dry it at 60° C. for 18 hours to obtain a composite sponge capable of absorbing viscous crude oil.

Embodiment 2

[0038] (1) Add 90 mg of graphene oxide powder to 30 ml of pure water, and use an ultrasonic cell disruptor to ultrasonicate for 30 min at 100 W to prepare a 3 mg / ml graphene oxide stock solution;

[0039] (2) Take 4.667ml graphene oxide stock solution, add 9.305ml pure water, 28μL ammonia water and 12.3mg L-ascorbic acid;

[0040] (3) Put the melamine sponge and the above solution into a 20ml hydrothermal reaction kettle for hydrothermal reaction, the hydrothermal reaction temperature is 95°C, and the time is 60min;

[0041] (4) Take out the reacted sponge and dry it at 60° C. for 18 hours to obtain a composite sponge capable of absorbing viscous crude oil.

Embodiment 3

[0043] (1) Add 90 mg of graphene oxide powder to 30 ml of pure water, and use an ultrasonic cell disruptor at 300W for 10 minutes of ultrasound to prepare a 3 mg / ml graphene oxide stock solution;

[0044] (2) Take 9.333ml graphene oxide stock solution, add 4.639ml pure water, 28μL ammonia water and 12.3mg L-ascorbic acid;

[0045] (3) Put the melamine sponge and the above solution into a 20ml hydrothermal reaction kettle for hydrothermal reaction, the hydrothermal reaction temperature is 95°C, and the time is 60min;

[0046] (4) Take out the reacted sponge and dry it at 60° C. for 18 hours to obtain a composite sponge capable of absorbing viscous crude oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com