Tungsten carbide-nickel-palladium composite material and preparation method threrof, and application of composite material in fuel cells

A composite material and tungsten carbide technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as poor stability and particle agglomeration, and achieve the effects of stable combination, high catalytic activity, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

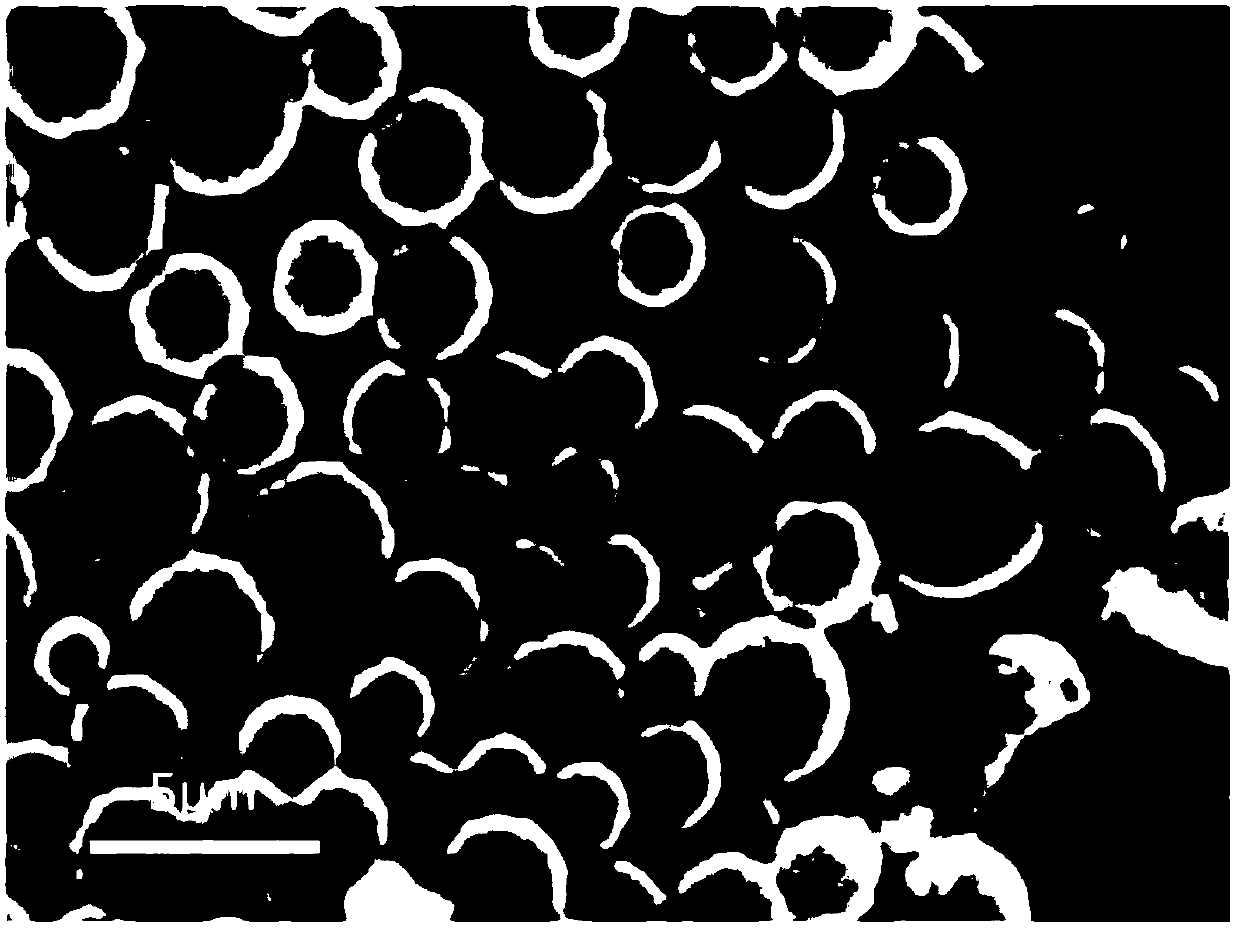

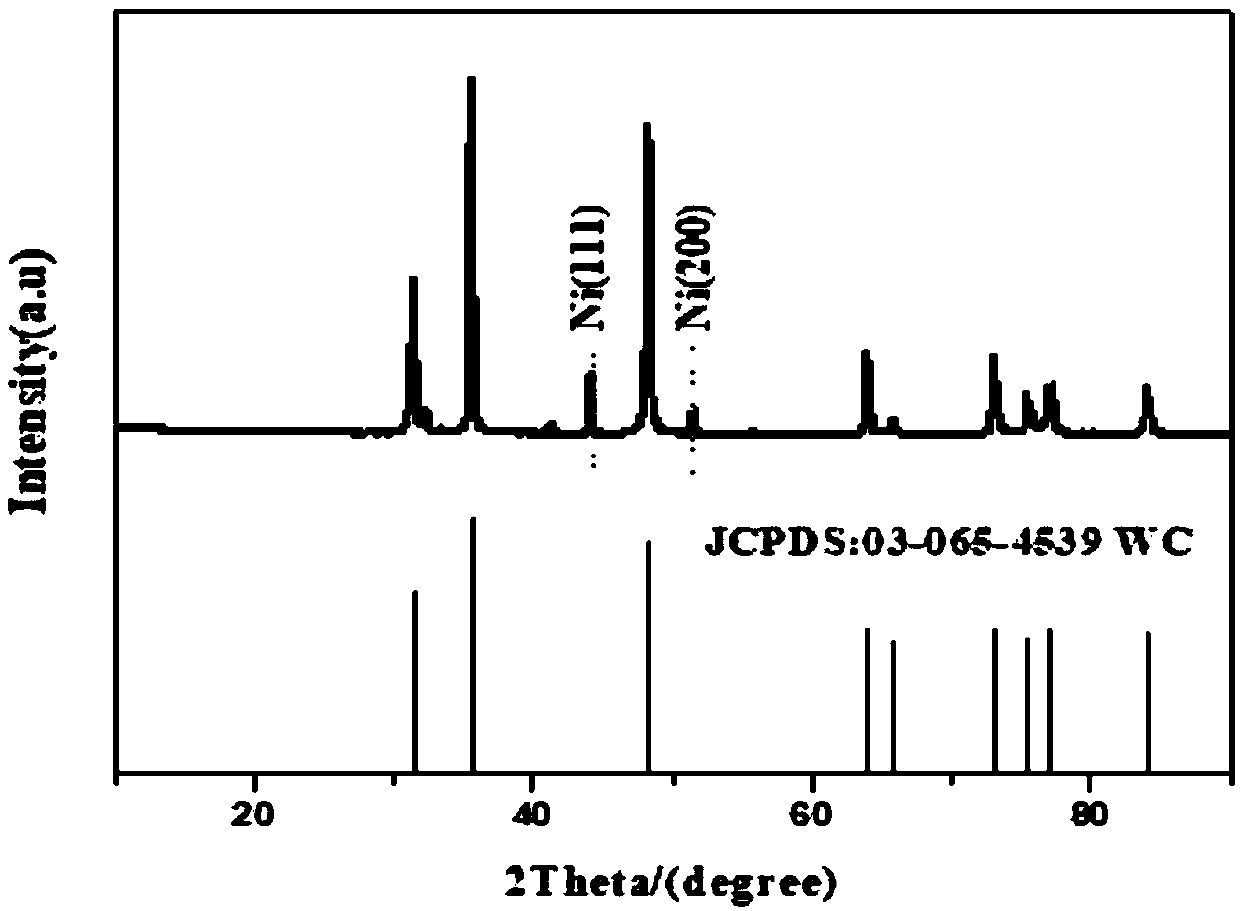

[0038] Mix ammonium metatungstate and nickel sulfate at a mass ratio of 5:1.5, and add deionized water to prepare a 25wt% solution. In the present invention, the mixed solution of ammonium metatungstate and nickel sulfate is preferably mixed by magnetic stirring for 20 minutes, and then mixed with crystals at 24-28°C for 36 hours. After the precipitated crystals are precipitated and dried, they are placed in a muffle The furnace was calcined at 600°C for 2 hours, and the calcined solid particles were treated with 0.7M sodium hydroxide solution for 20 minutes. During the pore-forming process, the solution was heated to 60°C, and the dried sample was reduced to carbonization. The carbonization atmosphere was: 100 sccm of CO, Using the temperature programming-gas-solid reaction method, the temperature was raised to 300 °C at a stepwise programming rate of 5 °C / min, and then the temperature was raised to 900 °C at a stepwise programming rate of 2 °C / min for 3 hours. The obtained p...

Embodiment 2

[0040] Mix ammonium metatungstate and nickel sulfate at a mass ratio of 5:1, and add deionized water to make a 10wt% solution. The mixed solution of ammonium metatungstate and nickel sulfate prepared is magnetically stirred for 10 minutes to fully mix it, then carry out crystal blending culture at 24-28°C for 24 hours, and the precipitated crystals are precipitated and dried, then put into a muffle furnace for calcination at 500°C For 1 hour, the calcined solid particles were treated with 0.1M sodium hydroxide solution for 10 minutes. During the pore-forming process, the temperature of the solution was controlled at 20 ° C. The dried sample was reduced to carbonization. The carbonization atmosphere was: 100 sccm of CO, using a temperature program -The gas-solid reaction method raises the temperature to 700° C. at a stepwise heating rate of 1° C. / min and keeps it for 1 hour. The obtained particles are immersed in a 2mmol / L palladium chloride solution at a temperature of 20°C, a...

Embodiment 3

[0042] Mix ammonium metatungstate and nickel sulfate at a mass ratio of 5:3, add deionized water to prepare a 30wt% solution. In the present invention, the mixed solution of ammonium metatungstate and nickel sulfate is preferably mixed by magnetic stirring for 40 minutes, and then mixed with crystals at 24-28°C for 48 hours. After the precipitated crystals are precipitated and dried, they are placed in a muffle furnace. Calcined at 700°C for 3 hours, the calcined solid particles were treated with 1.5M sodium hydroxide solution for 40min for pore-forming treatment, the solution was heated to 70°C, and the dried sample was reduced to carbonization. The carbonization atmosphere was: 100 sccm of CO, using In the temperature-programmed-gas-solid reaction method, the temperature was raised to 900°C at a rate of 10°C / min and kept for 8 hours. The obtained particles are immersed in a 10mmol / L palladium chloride solution at a temperature of 100°C, and the palladium chloride solution is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com