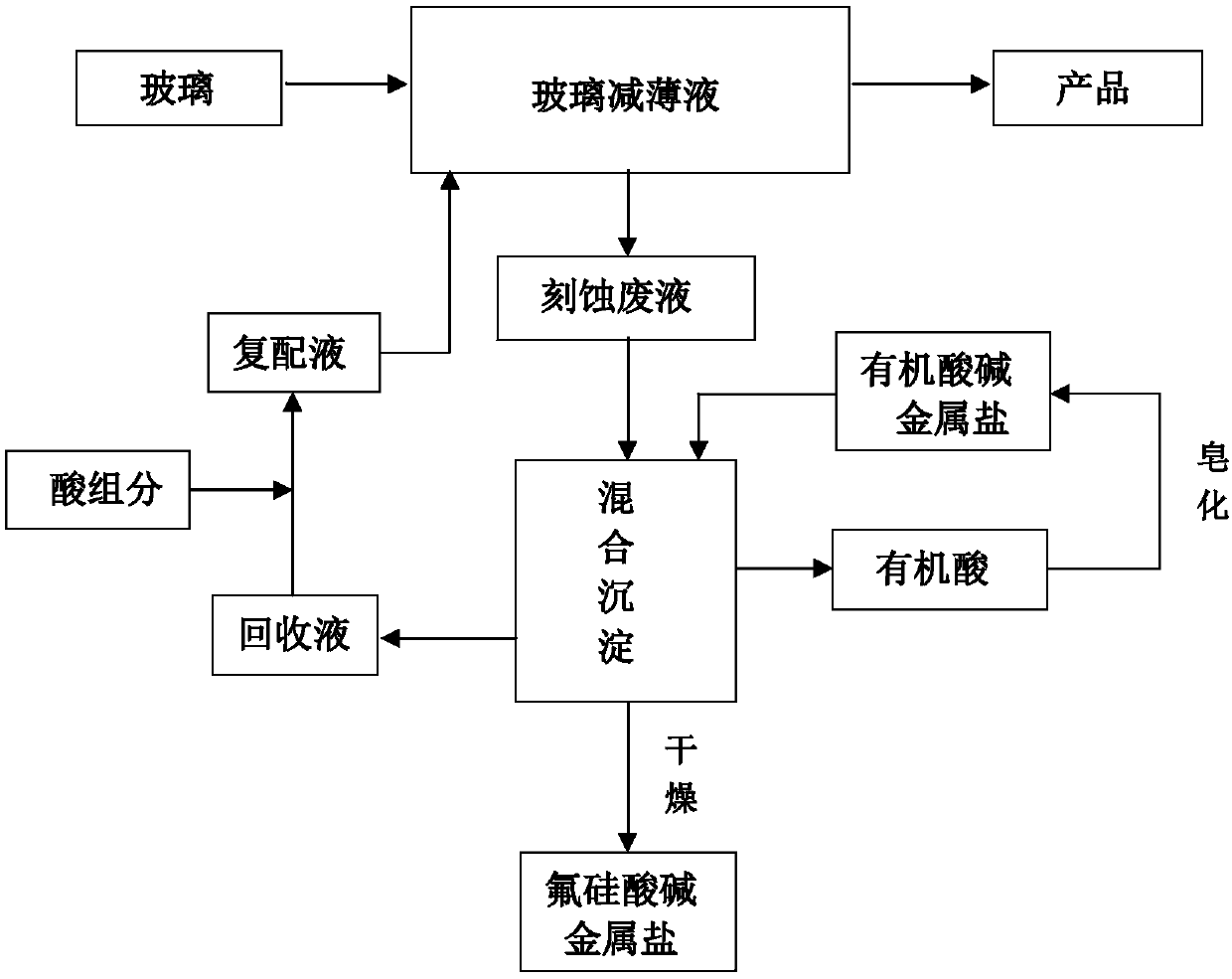

Method for online recovering and recycling of fluorine-containing glass thinning waste liquid in glass thinning industry

A technology for glass thinning and waste liquid recovery, applied in chemical instruments and methods, multi-stage water/sewage treatment, water pollutants, etc., can solve problems such as high acid component content, achieve fast sedimentation rate, and avoid waste of resources , the mild effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Configure simulated glass thinning waste liquid, its composition is 10% HF, 2% H by weight 2 SO 4, 5% HCl, 5% H 2 SiF 6 , 5%NH 4 HF 2 .

[0040] 1) Take 200g of the simulated glass thinning waste liquid in plastic beakers numbered 1, 2, 3, and 4 respectively, and add sodium oleate solid to the beaker so that the molar ratios of sodium oleate and fluorosilicic acid are 1.0, 2.0, 3.0, 4.0, 5.0, keep stirring for 2H, so that the solid and liquid can fully contact and react;

[0041] 2) Stop stirring and let it stand for 20 minutes, so that the precipitate in the mixed solution naturally settles at the bottom of the beaker, and the formed oleic acid and the treatment solution are completely separated;

[0042] 3) separating the precipitate at the bottom, washing and drying to obtain a solid sodium fluorosilicate;

[0043] 4) Transfer the upper layer of oleic acid to another plastic beaker, add 30% NaOH solution in a molar ratio of 1.0, fully stir and react, and dry f...

Embodiment 2

[0046] Configure 4 kinds of simulated glass thinning waste liquids, respectively numbered as A, B, C, D, E, and the composition of which is H 2 SiF 6 2%, 4%, 6%, 8%, 10% by weight, the remaining components are 10% HF, 2% H 2 SO 4 , 5% HCl, and 5% NH 4 HF 2 .

[0047] 1) Take 200g of the simulated glass thinning waste liquid respectively in plastic beakers numbered 1, 2, 3, 4, 5, and add potassium octanoate solid to the beaker, so that the molar ratio of potassium octanoate to fluorosilicic acid is 2.5, Stir continuously for 2H, so that the solid and liquid are fully contacted and reacted;

[0048] 2) Stop stirring and let it stand for 20 minutes, so that the precipitate in the mixed solution naturally settles at the bottom of the beaker, and the octanoic acid formed is completely separated from the treatment solution;

[0049] 3) The bottom precipitate is separated, washed and dried to obtain potassium fluorosilicate solid;

[0050] 4) Transfer the octanoic acid in the ...

Embodiment 3

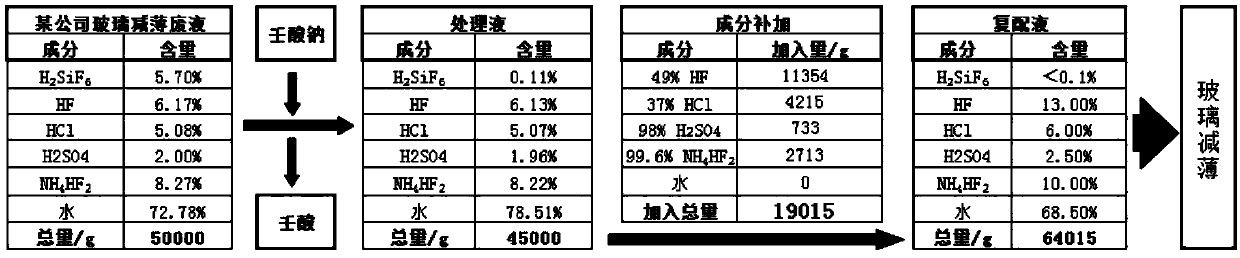

[0053] The glass thinning waste liquid in the original manufacturing process of a certain unit, its composition is 6.17% HF, 2% H by weight 2 SO 4 , 5.08% HCl, 5.70% H 2 SiF 6 and 8.27% NH 4 HF 2 .

[0054] 1) Take 200g of the simulated glass thinning waste liquid respectively in plastic beakers numbered 1, 2, 3, and 4, and add sodium hexanoate solid into the beaker so that the molar ratio of sodium hexanoate to fluorosilicic acid is 1.6, 2.0, 2.4, 2.8, 3.2, keep stirring for 2H, so that the solid and liquid are fully contacted and reacted;

[0055] 2) Stop stirring and let it stand for 20 minutes, so that the precipitate in the mixed solution naturally settles at the bottom of the beaker, and the hexanoic acid formed is completely separated from the treatment solution;

[0056] 3) separating the precipitate at the bottom, washing and drying to obtain a solid sodium fluorosilicate;

[0057] 4) Transfer the hexanoic acid in the upper layer to another plastic beaker, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com