Modified waterborne alkyd insulating varnish resin

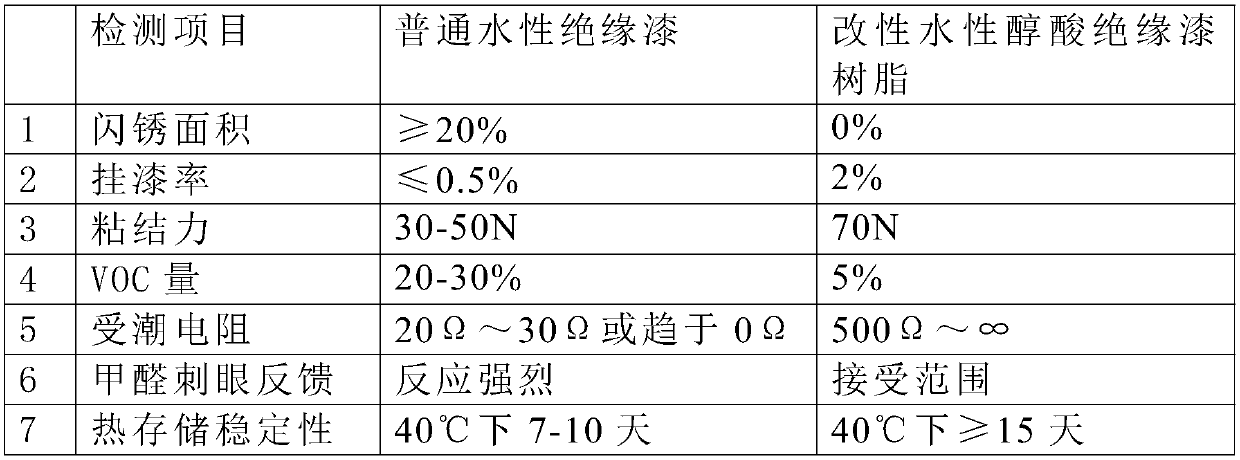

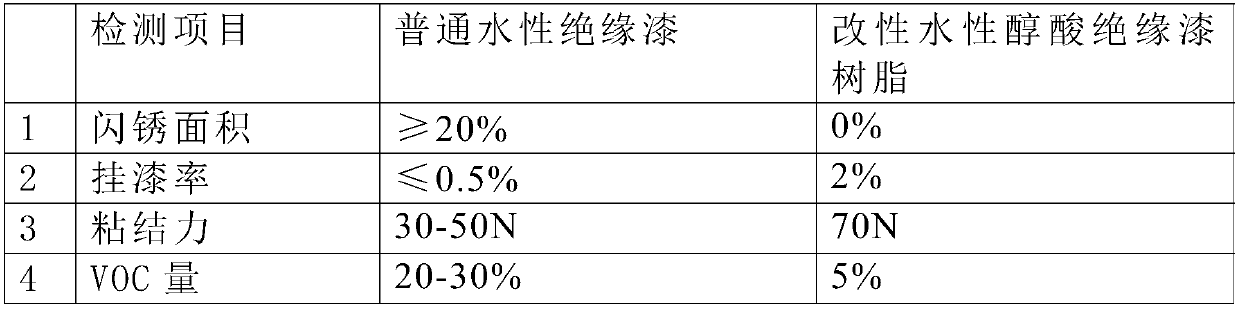

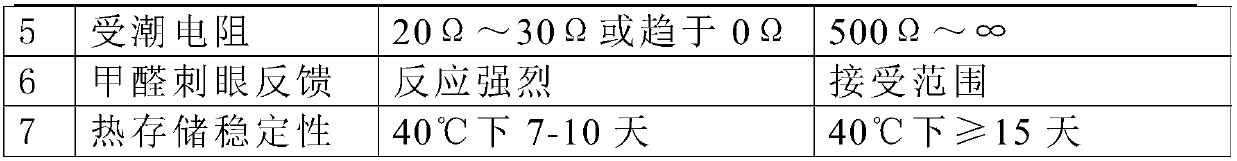

A technology of water-based alkyd and insulating varnish, which is applied in coating, polyurea/polyurethane coating, etc., can solve the problems of uneven paint hanging on motor windings, volatile irritating medium, and zero resistance to moisture, so as to avoid eye irritation, Increase molecular polarity and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The modified water-based alkyd insulating varnish resin includes the following raw materials in parts by weight:

[0044] Trimethylolpropane 70 parts

[0045] 70 parts of isophthalic acid

[0046] 5-SSIPA 15 parts

[0047] Vegetable oleic acid 70 parts

[0048] 25 parts of acrylic acid prepolymer containing vegetable oil

[0049] 25 parts of ethylene glycol tert-butyl ether

[0050] Polyvinyl urea 18 parts

[0051] Nano silicon oxide hybrid organosiloxane 18 parts

[0052] 500 parts of tap water

[0053] Amino curing agent 75 parts.

[0054] Trimethylolpropane acts as a regulator of polyols and hydrophilic groups.

[0055] Isophthalic acid acts as a dibasic acid. Because isophthalic acid does not undergo intermolecular cyclization, it can make the entire modified water-based alkyd insulating varnish resin have the characteristics of high molecular weight and high viscosity.

[0056] 5-SSIPA is isophthalic acid-5-sulfonate sodium polyester is an intermediate and...

Embodiment 2

[0069] The modified water-based alkyd insulating varnish resin includes the following raw materials in parts by weight:

[0070] Trimethylolpropane 90 parts

[0071] 90 parts of isophthalic acid

[0072] 5-SSIPA 25 parts

[0073] Vegetable oleic acid 90 parts

[0074] 35 parts of acrylic acid prepolymer containing vegetable oil

[0075] 35 parts of ethylene glycol tert-butyl ether

[0076] Polyvinyl urea 22 parts

[0077] Nano silicon oxide hybrid organosiloxane 22 parts

[0078] 600 parts of tap water

[0079] Amino curing agent 95 parts.

[0080] Trimethylolpropane acts as a regulator of polyols and hydrophilic groups.

[0081] Isophthalic acid acts as a dibasic acid. Because isophthalic acid does not undergo intermolecular cyclization, it can make the entire modified water-based alkyd insulating varnish resin have the characteristics of high molecular weight and high viscosity.

[0082] 5-SSIPA is isophthalic acid-5-sulfonate sodium polyester is an intermediate and...

Embodiment 3

[0097] The modified water-based alkyd insulating varnish resin includes the following raw materials in parts by weight:

[0098] Trimethylolpropane 80 parts

[0099] 80 parts of isophthalic acid

[0100] 5-SSIPA 21 parts

[0101] Vegetable oleic acid 79 parts

[0102] 27 parts of acrylic acid prepolymer containing vegetable oil

[0103] 29 parts of ethylene glycol tert-butyl ether

[0104] Polyvinyl urea 19 parts

[0105] Nano silicon oxide hybrid organosiloxane 20 parts

[0106] 560 parts of tap water

[0107] Amino curing agent 80 parts.

[0108] Trimethylolpropane acts as a regulator of polyols and hydrophilic groups.

[0109] Isophthalic acid acts as a dibasic acid. Because isophthalic acid does not undergo intermolecular cyclization, it can make the entire modified water-based alkyd insulating varnish resin have the characteristics of high molecular weight and high viscosity.

[0110] 5-SSIPA is isophthalic acid-5-sulfonate sodium polyester is an intermediate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com