Organic silica gel adhesive

A silicone adhesive, an organic technology, applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc., to achieve environmental governance and protection, improve flexibility, improve water resistance and heat and humidity resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

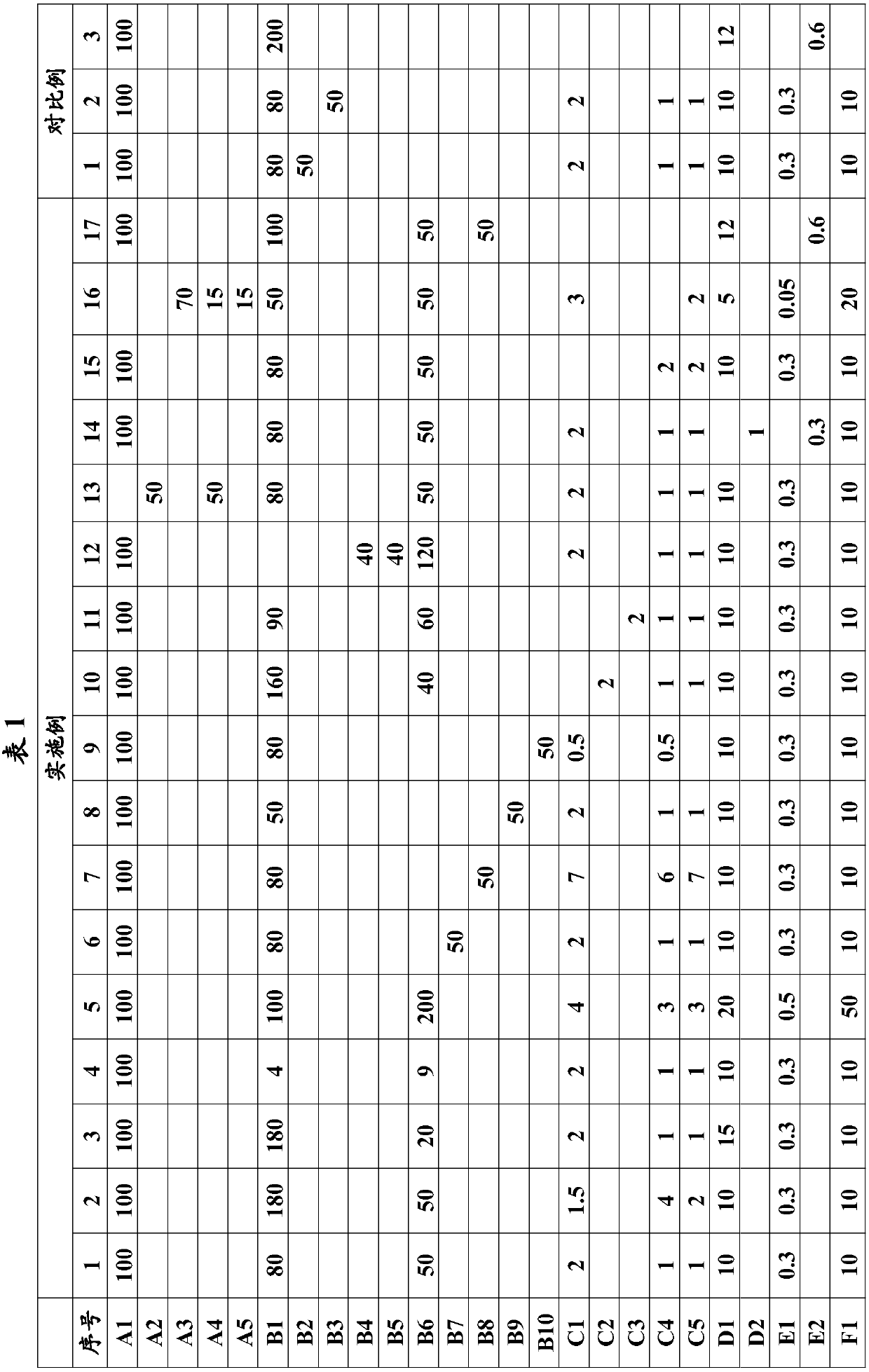

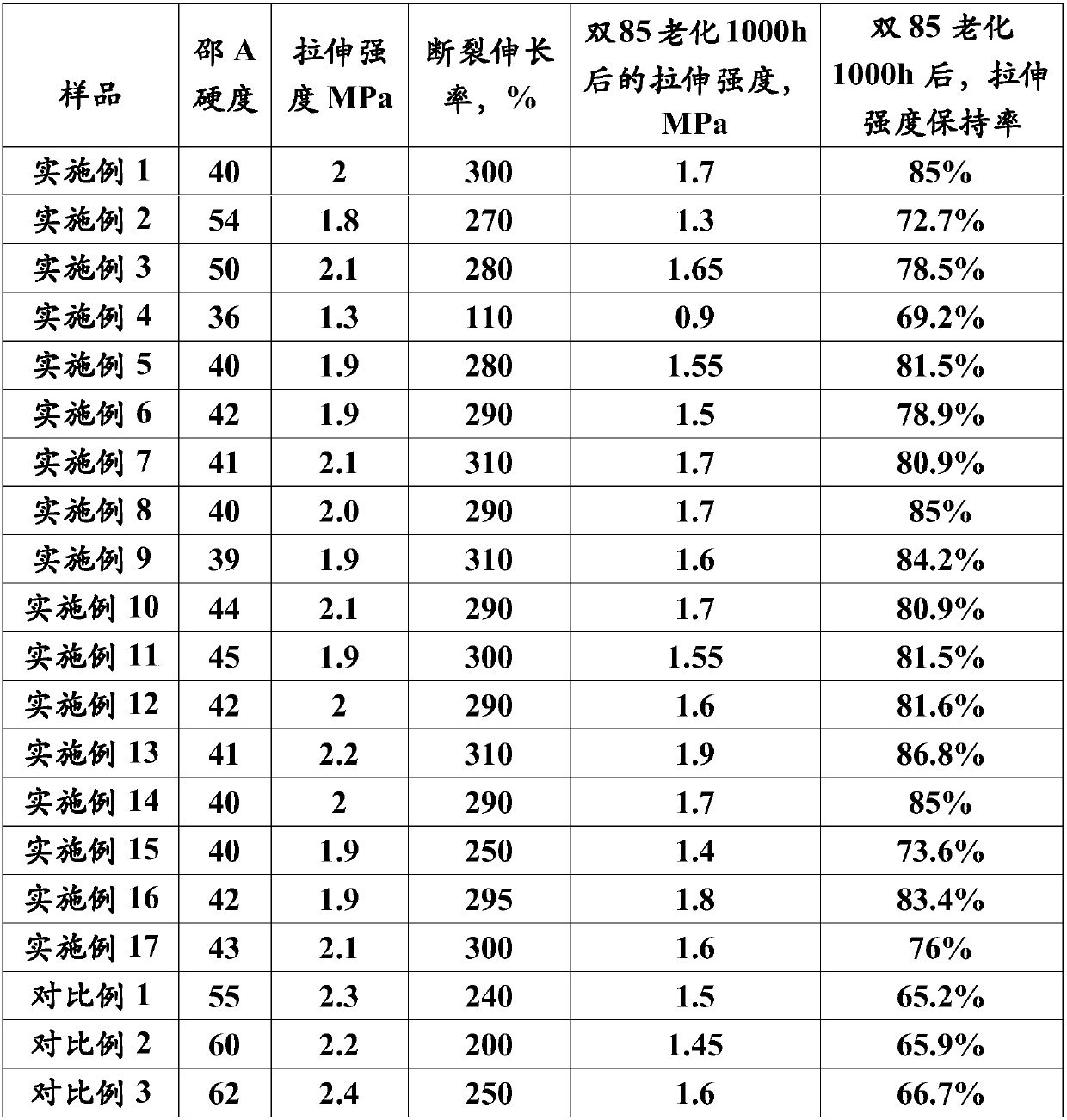

Embodiment 1-17 and comparative example 1-3

[0051] The raw materials and consumption involved in each embodiment and comparative example are as follows:

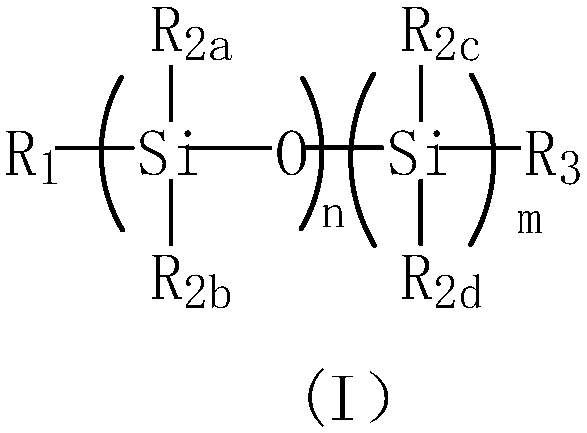

[0052] Polysiloxane:

[0053] A1 20000mPa.s hydroxyl-terminated polydimethylsiloxane (Xin'an Chemical)

[0054] A2 80000mPa.s hydroxyl-terminated polydimethylsiloxane (Xin'an Chemical)

Embodiment 1

[0055] A3 50000mPa.s Vinyldimethoxysilane-terminated α, ω-dihydroxypolydimethylsiloxane (prepared according to Example 1 of the Chinese patent application 201410155699.9 specification)

[0056] A4 1000mPa.s hydroxyl-terminated polydimethylsiloxane (Dow Silicone (Zhangjiagang) Co., Ltd.)

[0057] A5 hydroxyl MQ resin YDSR1002 (Shanghai Yandi New Material Technology Co., Ltd.)

[0058] filler

[0059] B1 Calcium Carbonate (Guangxi Huana New Material Technology Co., Ltd., CCS-18)

[0060] B2 Calcium Carbonate (Zhejiang Tianshi Nano Technology Co., Ltd., TN-M3)

[0061] B3 microsilica powder (Guangdong Yufeng Powder Material Co., Ltd.)

[0062] B4 Aluminum Hydroxide (Foshan Vikede Chemical Materials Co., Ltd., FA-50K)

[0063] B5 Alumina (Foshan Vikede Chemical Materials Co., Ltd., AR-30)

[0064] B6 80 mesh recycled waste tire rubber powder (natural rubber as the main component)

[0065] B7 600 mesh tire rubber powder (styrene butadiene rubber)

[0066] B8 200 mesh waste h...

Embodiment 2-17 and comparative example 1-3

[0085] According to the similar operation described in Example 1, a silicone adhesive was prepared according to the formula shown in Table 1 below. For the addition of the silane coupling agent, the timing of adding the two components of the silane coupling agent C2 and C3 is consistent with that of the silane coupling agent C1.

[0086]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com