Preparation and application of a noble metal in-situ co-doped CuO-based NO2 gas-sensitive material

A technology of co-doping and noble metals, which is applied in the field of preparation of CuO-based nanomaterials, can solve the problems of poor gas-sensing performance, achieve the effects of improving sensitivity, good development prospects, and reducing operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

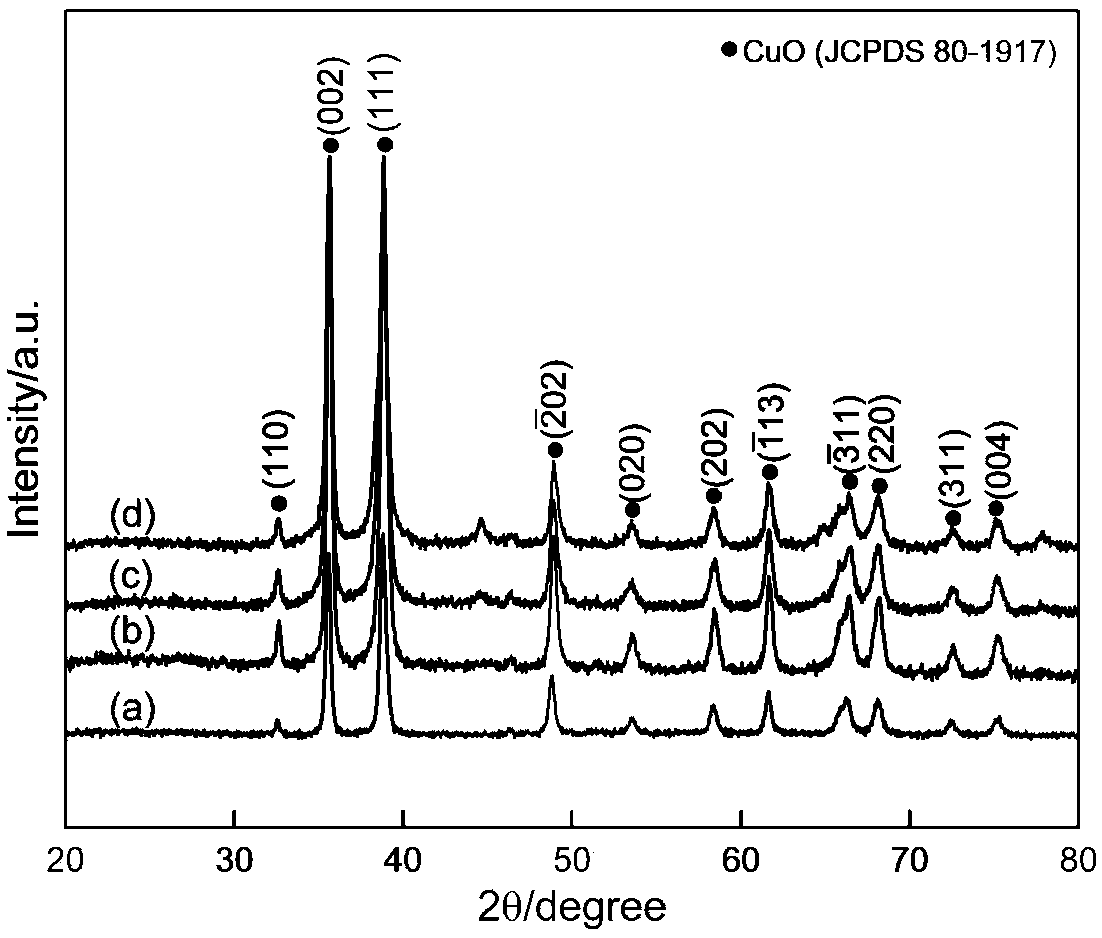

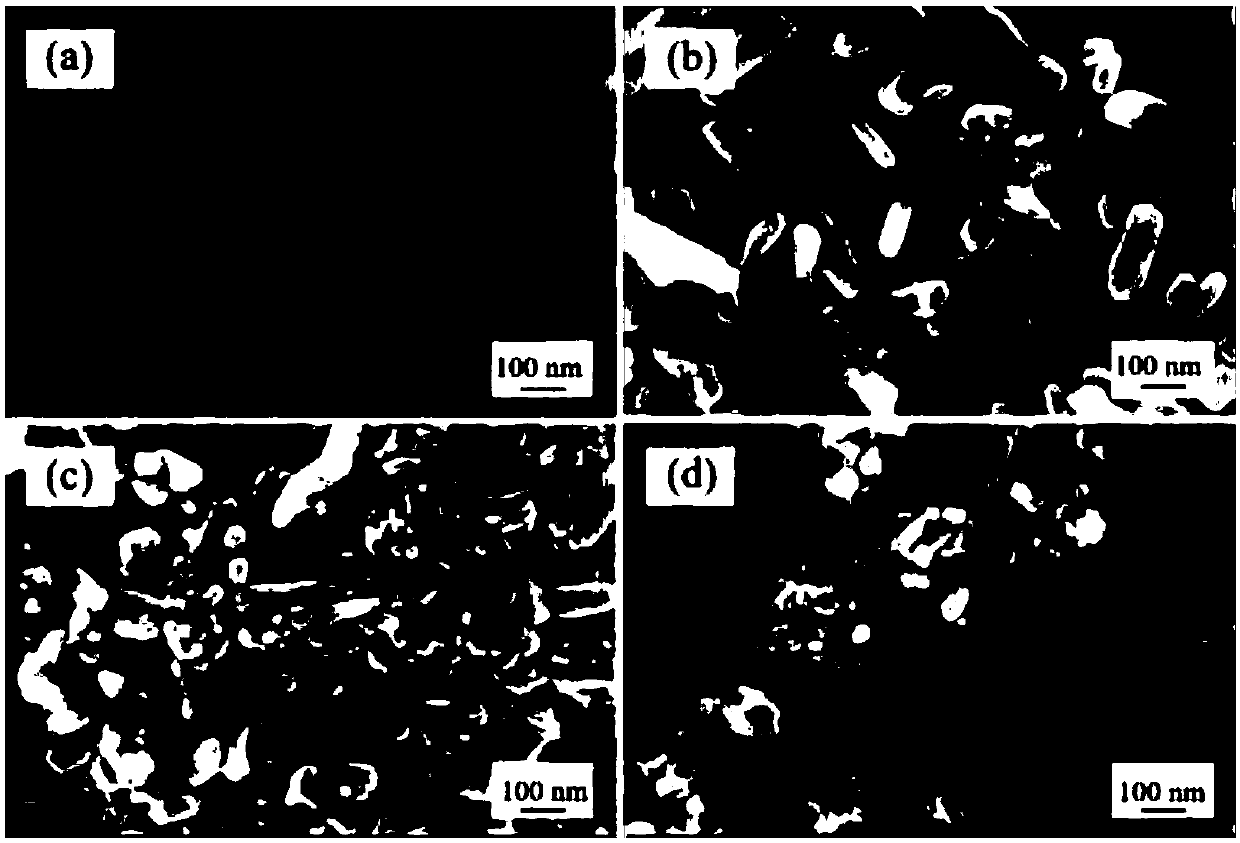

Embodiment 1

[0042] In embodiment 1, 375 μ L concentration is the chloroauric acid solution of 0.017 mol / L and 650 μ L concentration is the palladium chloride solution of 0.01 mol / L, and Au atomic mole number is 0.6375*10 -2 mmol, Pd atomic mole number 0.65*10 -2 mmol, the atomic molar number of Cu is 1.3mmol, so the atomic molar number Au / Pd is about 1:1, and the atomic molar ratio of (Au+Pd) / Cu is 1%.

Embodiment 2

[0043] In embodiment 2, 750 μ L concentration is the chloroauric acid solution of 0.017 mol / L and 1300 μ L concentration is the palladium chloride solution of 0.01 mol / L, and Au atomic mole number is 1.275*10 -2 mmol, Pd atomic mole number 1.3*10 -2 mmol, Cu atomic molarity is 1.3mmol, so atomic molarity Au / Pd is about 1:1, (Au+Pd) / Cu atomic molar ratio is 2%.

Embodiment 3

[0044] In embodiment 3, 1875 μ L concentration is the chloroauric acid solution of 0.017 mol / L and 3250 μ L concentration is the palladium chloride solution of 0.01 mol / L, and Au atomic mole number is 3.1875*10 -2 mmol, Pd atomic mole number 3.25*10 -2 mmol, Cu atomic molarity is 1.3mmol, so atomic molarity Au / Pd is about 1:1, (Au+Pd) / Cu atomic molar ratio is 5%.

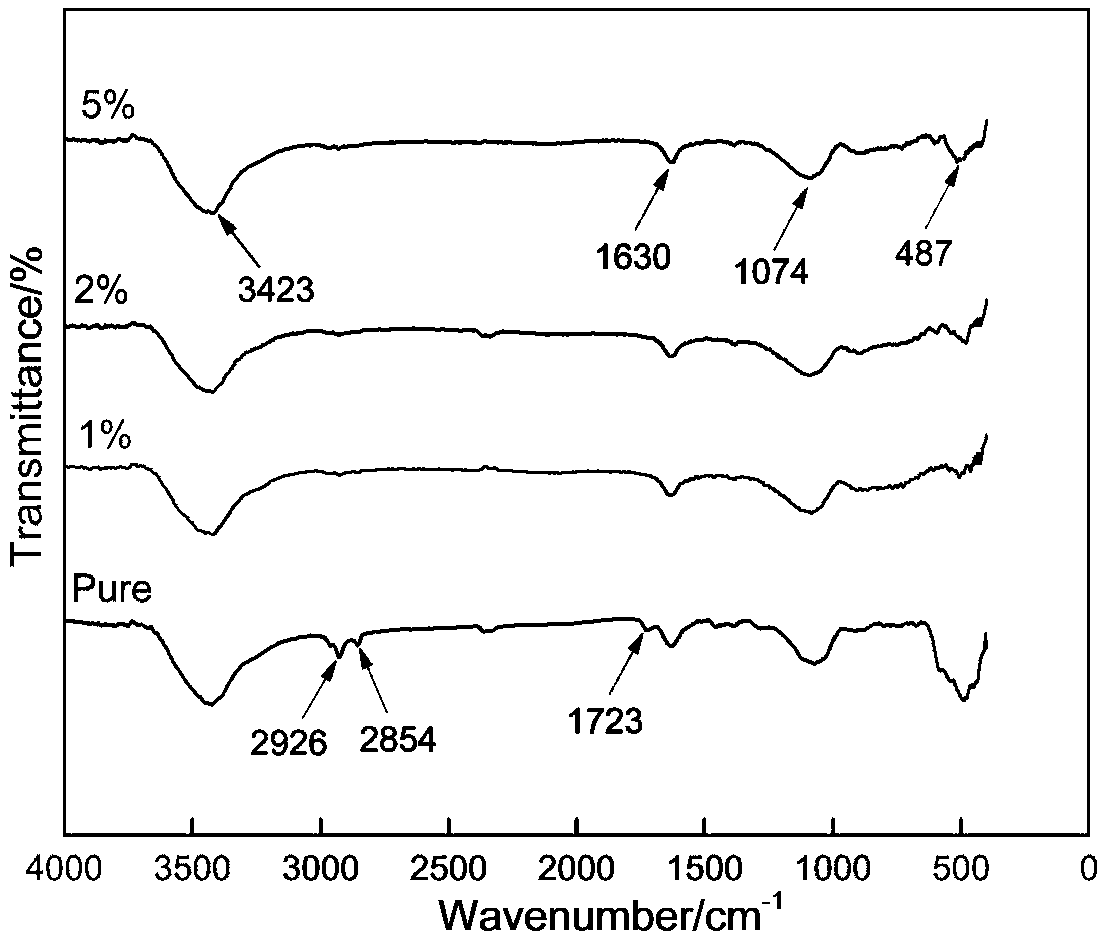

[0045] Example 1

[0046] The invention discloses a noble metal in-situ co-doped CuO-based NO 2 The preparation of gas-sensitive material comprises the steps:

[0047] ①Add 1.3mmol CuSO to 30mL deionized water 4 ·5H 2 O and 0.8mmol of trisodium citrate powder, after stirring for 15min, add 5mmol of NaOH powder into the solution, and continue stirring for 0.5h to obtain solution A;

[0048] ② Mix 375 μL of chloroauric acid solution with a concentration of 0.017 mol / L and 650 μL of a palladium chloride solution with a concentration of 0.01 mol / L. The doping atomic mole is 1% of the Cu atomic mole, add deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com