Two-sided differentiated textured structure for monocrystal silicon heterojunction solar cells and preparation method thereof

A solar cell and differentiated technology, applied in the field of solar cells, can solve the problems such as the inability to achieve the optimal design of the incident light anti-reflection effect, the inability to achieve the structure configuration of the double-sided solar cell film layer, and the reduction of the open circuit voltage of the heterojunction solar cell. , to reduce the carrier recombination probability, save process time, and increase the open circuit voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

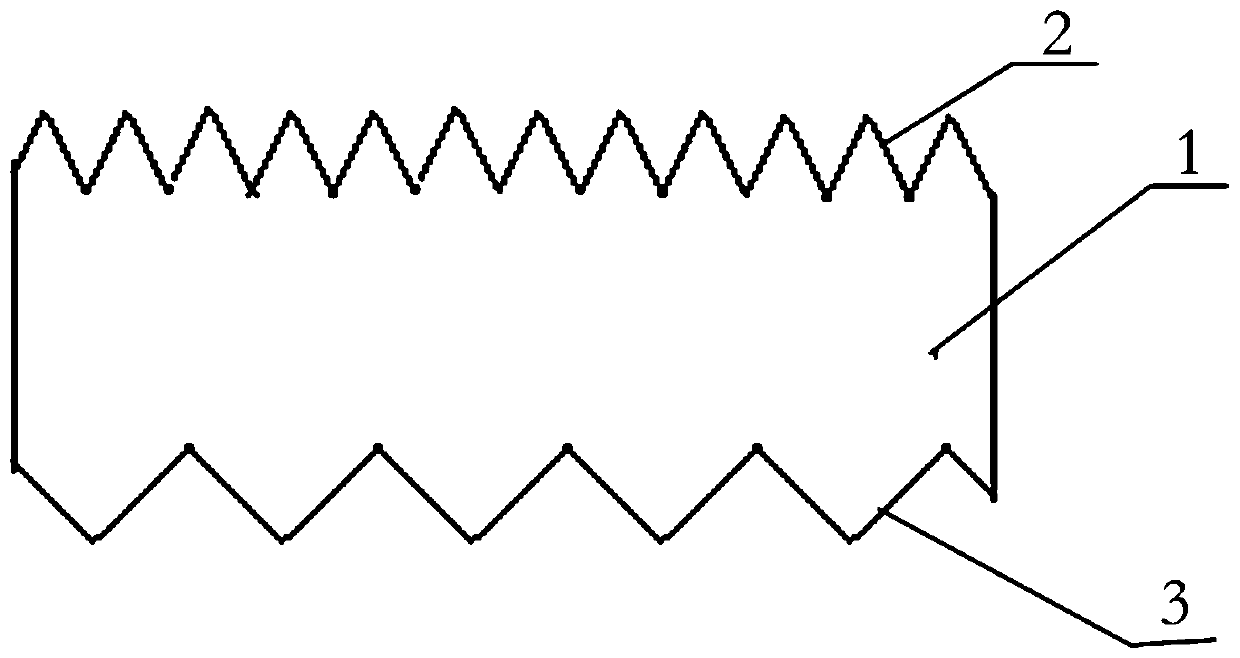

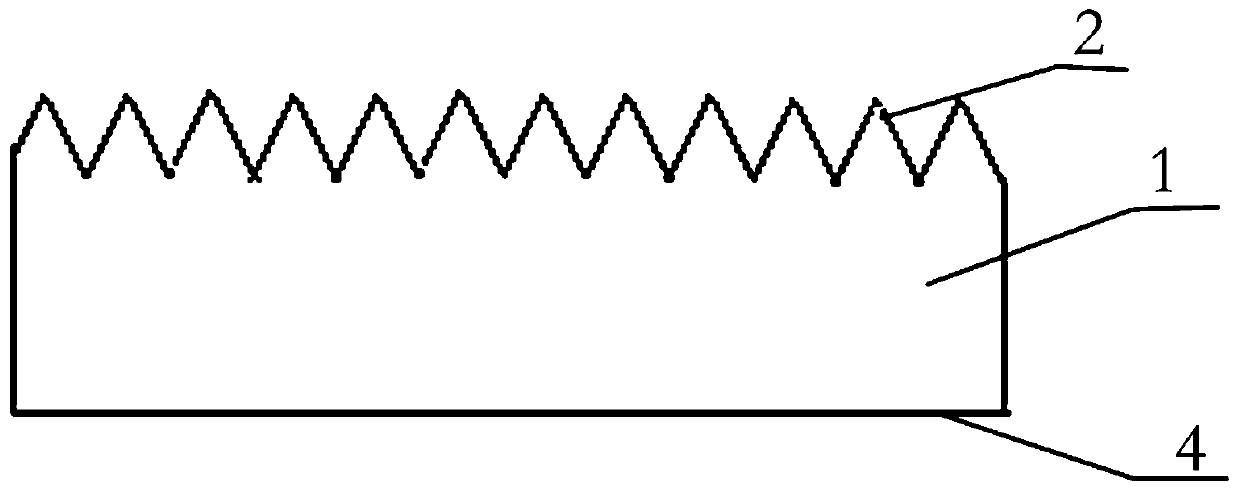

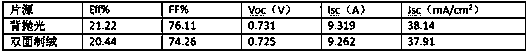

[0022] figure 1 Example 1 shown: a single-crystal silicon heterojunction solar cell with two-sided differentiated suede structure, the structure of the light-facing surface and the back-light surface of the silicon wafer 1 are different, the light-facing surface is a small pyramid structure 2, and the backlight surface is Large pyramid suede structure 3, small pyramid suede structure 2 with a size of 1-3 μm; large pyramid suede structure 3 with a size of 5-10 μm.

[0023] The preparation steps are as follows: for single crystal silicon wafers with a resistivity of 2Ω·cm, pre-clean them in a chain cleaning texturing machine, then enter the etching tank for texturing, and use continuous tanks to carry out alkali processing on the silicon wafers. In the first tank, the upper and lower surfaces of the silicon wafer are immersed in the solution, and the silicon wafer obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com