A method and device for growing microcrystalline silicon on the surface of a solar cell substrate

A technology for the surface of solar cells and substrates, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of insufficient passivation effect and current loss on the whole surface, so as to improve cell efficiency and reduce energy costs , the effect of increasing the fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

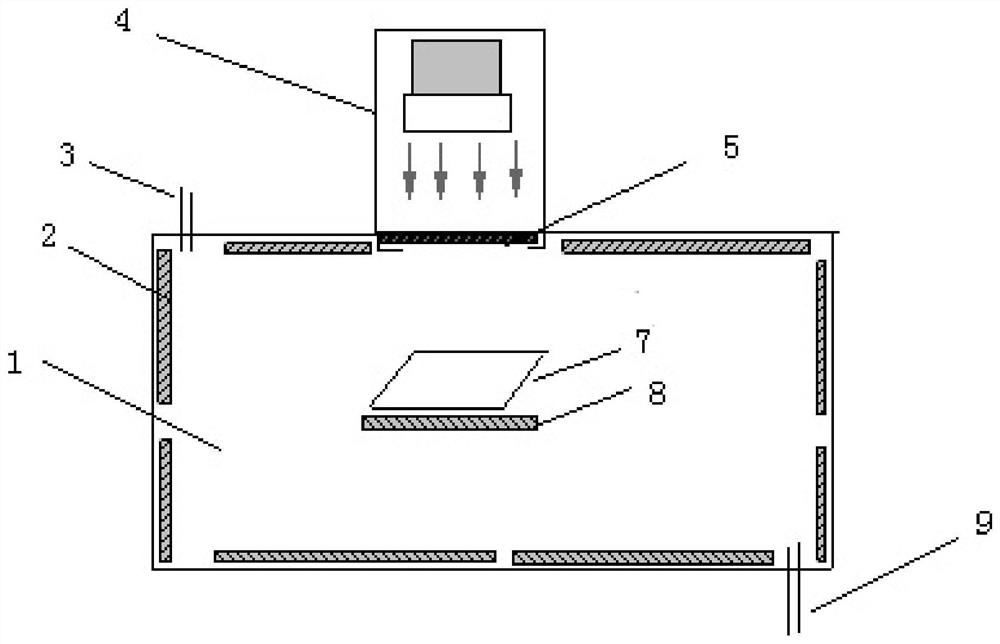

[0053] Such asfigure 1 The shown device for growing microcrystalline silicon on the surface of a solar cell substrate includes a closed cavity 1, a laser component 4, and the laser component 4 includes a laser, a scanning galvanometer and an optical component. The airtight cavity 1 is in the shape of a cuboid, and the laser is located outside the airtight cavity 1, and is specifically arranged in such as figure 1 On the outside of the top surface of the airtight cavity 1 shown, a transparent window 5 made of quartz is provided on an outer wall of the airtight cavity 1, that is, in the middle of the top surface. The transparent window 5 is rectangular, and there is a corresponding scanning window above the transparent window. The vibrating mirror and the laser, the laser and the scanning vibrating mirror are integrated and fixed in a shield fixedly connected with the airtight cavity 1 . Inside the airtight cavity 1 there is a stage 7 for placing the solar cell substrate, and th...

Embodiment 2

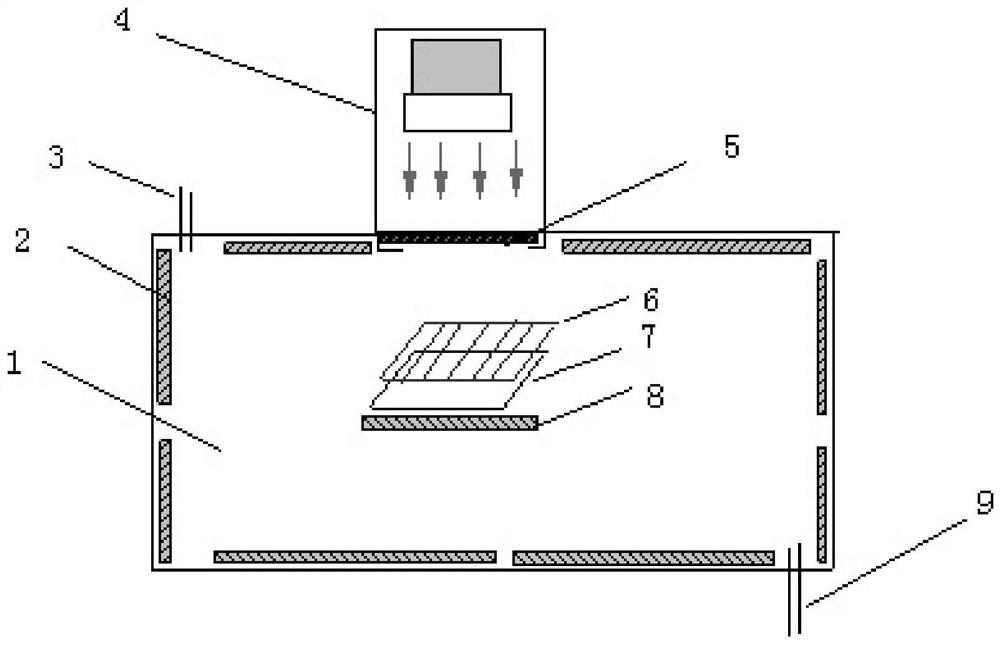

[0064] The difference between this embodiment and Embodiment 1 is that, as figure 2 As shown, in the device for growing microcrystalline silicon on the surface of a solar cell substrate in this embodiment, the laser emitted by the laser is a surface light source, and a mask 6 is set above the solar cell substrate, and the mask is positioned between the transparent window 5 and the solar cell substrate placed on the stage 7. The mask is a special component for solar cell manufacturing. For its structure and principle, please refer to the invention patent application number 201310505063.8 "New mask and use of ion implanter". The common one is graphite mask, which can be square or round as a whole. Etc., a part of the mask plate is hollowed out, and the hollowed out shape can be a hole shape, a stripe shape or a grid shape. Other implementation steps of this embodiment are the same as those of Example 1, wherein the graphite mask can be replaced by a ceramic mask or a quartz ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com