Heavy metal sewage composite treatment agent and preparation method and application thereof

A composite treatment and heavy metal technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Improve the utilization rate, improve the adsorption efficiency, and the effect of not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

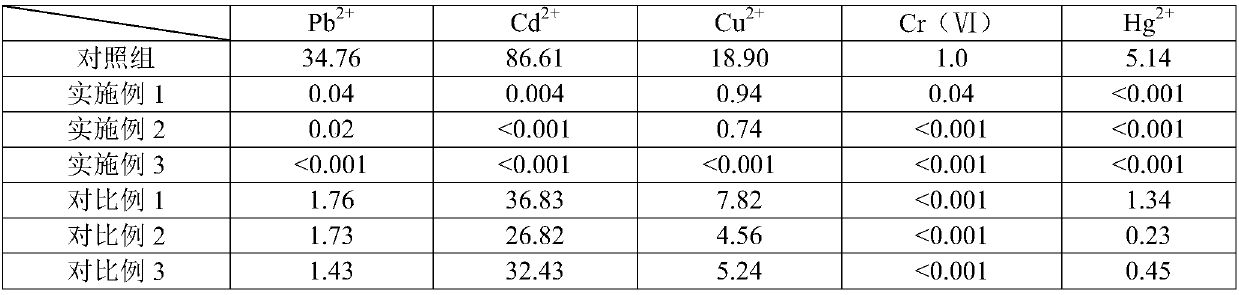

Examples

Embodiment 1

[0043] A compound treatment agent for heavy metal sewage, made of the following raw materials in parts by weight: 20 parts of pumpkin vine, 20 parts of xanthic acid modified quartz sand, 4 parts of sodium alginate, 10-30 parts of humic acid, 4 parts of chitosan Sugar, 4 parts calcium thioglycolate, 3 parts calcium chloride.

[0044] Described xanthic acid modified quartz sand is made of quartz sand, aminosilane coupling agent, CS 2 It is prepared according to the weight ratio of 1:0.2:0.14.

[0045] The particle size of the quartz sand is 100-200 mesh.

[0046] Its preparation method comprises the following steps:

[0047] (1) Take 100g of quartz sand passing through a 100-200 mesh sieve, wash with water, soak in 200g of 20% sulfuric acid solution for 24 hours, filter, then wash with water until neutral, dry in an oven at 105°C to constant weight, and store for later use;

[0048] (2) Weigh 50 g of the quartz sand in step (1), disperse it in an ethanol solution to form a tu...

Embodiment 2

[0058] A compound treatment agent for heavy metal sewage, prepared from the following raw materials: 25 parts of pumpkin vine waste, 25 parts of xanthic acid modified quartz sand, 5 parts of sodium alginate, 10-30 parts of humic acid, and 5 parts of chitosan Sugar, 7 parts calcium thioglycolate, 4.5 parts calcium chloride.

[0059] The xanthate-modified quartz sand is prepared from quartz sand, aminosilane coupling agent and sodium ethyl xanthate in a weight ratio of 1:0.2:0.13.

[0060] The particle size of the quartz sand is 100-200 mesh.

[0061] Its preparation method comprises the following steps:

[0062] (1) Take 100 g of quartz sand that has passed through a 100-200 mesh sieve, wash it with water, soak it in 200 g of 30% sulfuric acid solution for 15 hours, filter, then wash it with water until neutral, dry it in an oven at 105° C. to constant weight, and store it for later use;

[0063] (2) Weigh 50 g of the quartz sand in step (1), disperse it in an ethanol solutio...

Embodiment 3

[0073] A compound treatment agent for heavy metal sewage, prepared from the following raw materials: 30 parts of pumpkin vine waste, 30 parts of xanthic acid modified quartz sand, 6 parts of sodium alginate, 10-30 parts of humic acid, 6 parts of chitosan Sugar, 10 parts calcium thioglycolate, 6 parts calcium chloride.

[0074] Described xanthic acid modified quartz sand is made of quartz sand, aminosilane coupling agent, CS 2 It is prepared according to the weight ratio of 1:0.4:0.28.

[0075] The particle size of the quartz sand is 100-200 mesh.

[0076] Its preparation method comprises the following steps:

[0077] (1) Take 100g of quartz sand passing through a 100-200 mesh sieve, wash with water, soak in 200g of 30% sulfuric acid solution for 24h, filter, then wash with water until neutral, dry in an oven at 105°C to constant weight, and store for later use;

[0078] (2) Weigh 50 g of quartz sand in step (1), disperse it in an ethanol solution to form a turbid solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com