Application of a modified fiber in purifying voc

A modified fiber and fiber technology, which is applied in the application field of modified fiber in purifying VOC, can solve the problems of difficult shaping and processing, difficult regeneration, and large equipment volume, so as to reduce the processing cost, light weight and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

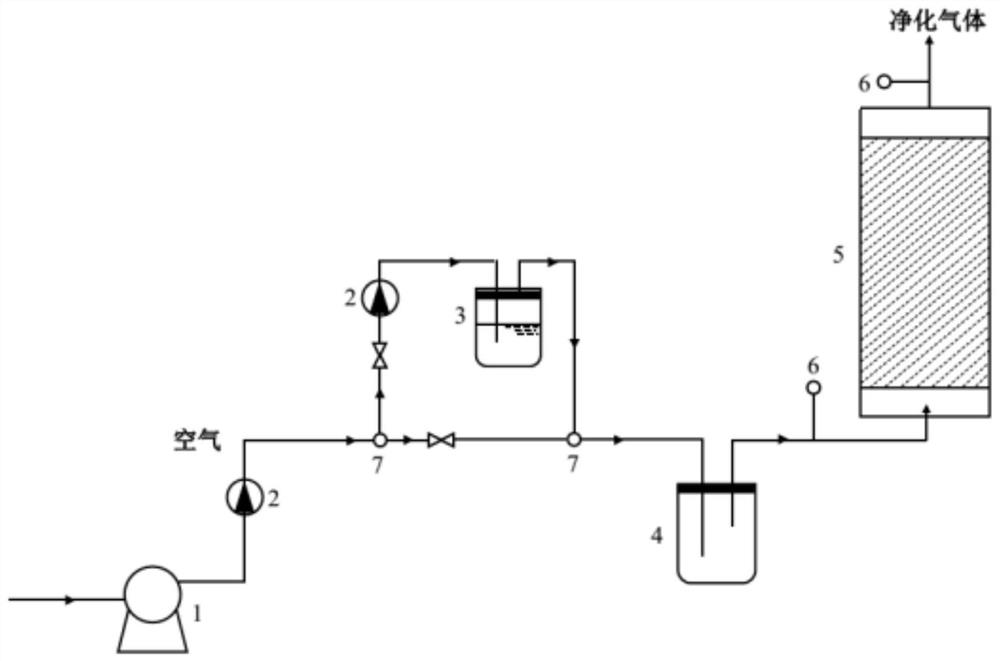

Method used

Image

Examples

Embodiment 1

[0031] Use 18% sodium hydroxide solution to alkaline activate the plant fibers for 2 hours, then wash with water until neutral, and dry for later use; add the activated plant fibers to acetic acid with a mass fraction of 36%, react at 70°C for 1 hour, and then Add acetic anhydride, under the catalysis of concentrated sulfuric acid with a mass fraction of 98%, react at 90°C for 2 hours, filter to obtain a modified fiber intermediate; immerse the modified fiber intermediate in a magnesium acetate solution with a mass fraction of 21% 10min, filter and wash to neutrality, and dry to obtain a mixture of cellulose triacetate and cellulose diacetate;

[0032] The plant fiber: acetic acid mass ratio is 1:5; the plant fiber: acetic anhydride mass ratio is 1:5; the plant fiber: concentrated sulfuric acid mass ratio is 1:0.01.

Embodiment 2

[0034] Use 18% sodium hydroxide solution to alkaline activate the plant fibers for 2 hours, then wash with water until neutral, and dry for later use; add the activated plant fibers to acetic acid with a mass fraction of 36%, react at 70°C for 1 hour, and then Add benzoic anhydride, under the catalysis of concentrated sulfuric acid with a mass fraction of 98%, react at 90°C for 2 hours, filter to obtain a modified fiber intermediate; immerse the modified fiber intermediate in a magnesium acetate solution with a mass fraction of 21% neutralize for 10 minutes, filter and wash until neutral, and dry to obtain a mixture of fiber tribenzoate and fiber dibenzoate;

[0035] The plant fiber: acetic acid mass ratio is 1:5; the plant fiber: benzoic anhydride mass ratio is 1:5; the plant fiber: concentrated sulfuric acid mass ratio is 1:0.01.

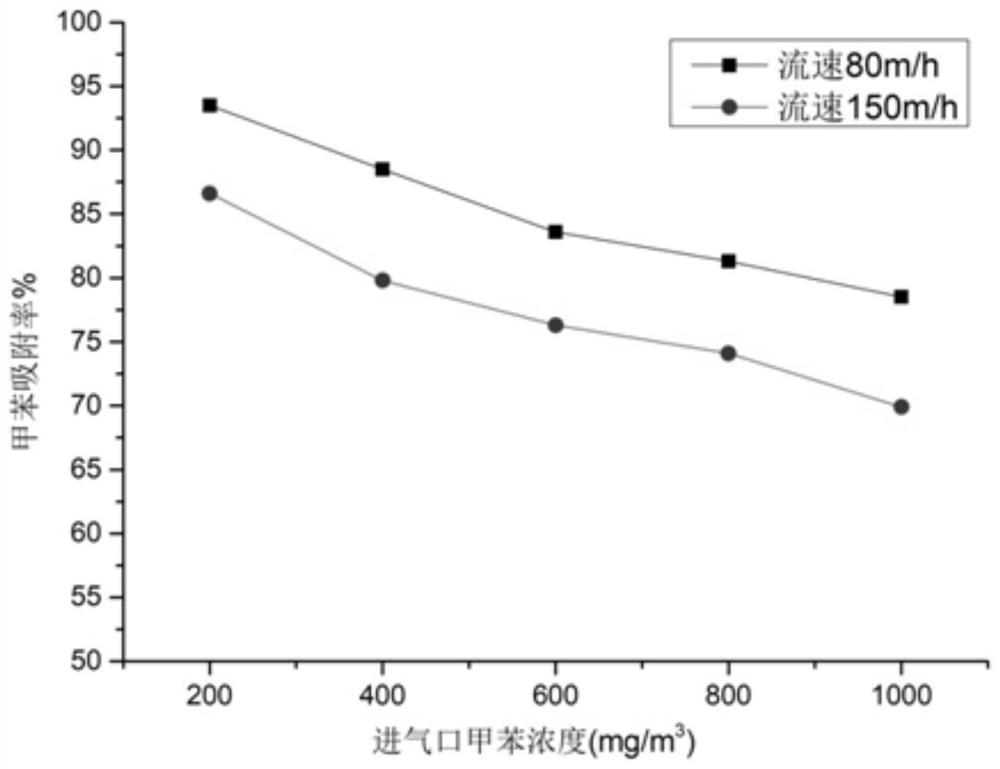

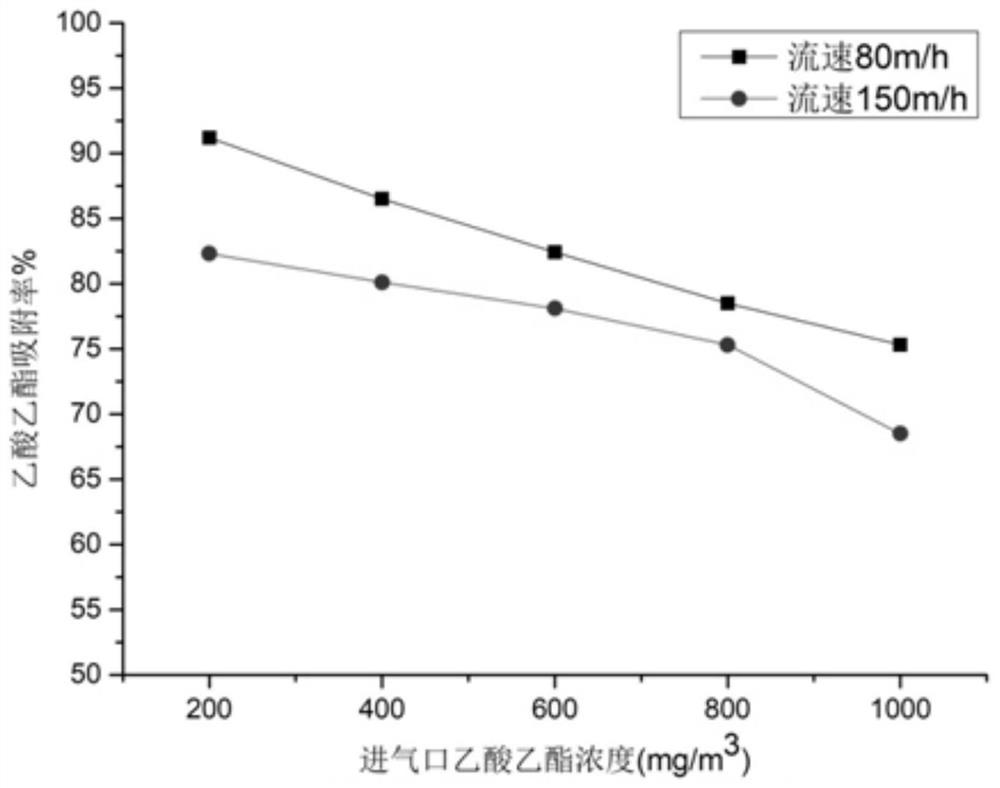

[0036] Application of Modified Fiber in VOC Purification

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com