Method for producing microbial thalli protein from livestock and poultry breeding wastewater

A technology for livestock and poultry breeding wastewater and microbial bacteria is applied in the field of microbial cell protein production from livestock and poultry breeding wastewater, which can solve the problems of high energy consumption and low utilization rate of resources, achieve low energy consumption, reduce wastewater treatment costs, and reduce Aeration energy consumption and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

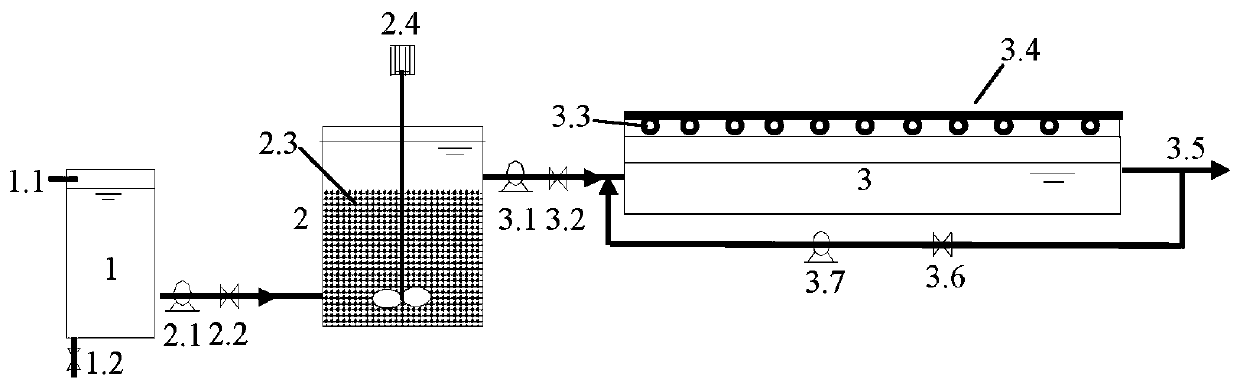

[0024] In the figure, 1 is the waste water tank; 2 is the fermentation acid production reactor; 3 is the shallow pool anaerobic infrared light reactor; 1.1 is the overflow pipe; 1.2 is the vent pipe; 2.1 is the fermentation acid production reactor inlet pump; 2.2 2.3 is the anaerobic biofilm; 2.4 is the agitator; 3.1 is the water inlet pump of the anaerobic infrared light reactor in the shallow pool; 3.2 is the water inlet valve of the anaerobic infrared light reactor in the shallow pool; 3.3 3.4 is the solar panel; 3.5 is the water inlet pipe of the shallow pool anaerobic infrared light reactor; 3.6 is the return valve of the purple photosynthetic bacteria mixture; 3.7 is the return pump of the purple photosynthetic bacteria mixture.

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as figure 1 As shown, the device used in the method for producing microbial thalline protein from livestock and poultry breedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com