Method for regenerating coenzyme-reduced glutathione based on electrochemistry and enzyme electrode

An enzyme electrode and electrode technology, applied in the field of enzyme electrodes, can solve the problems of low regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, for the preparation method of the enzyme electrode that is used to process DCM-containing wastewater, the following steps are carried out successively:

[0033] 1) Using graphite as the conductive material, the graphite is polished on the suede with alumina powders with diameters of 1.0, 0.3, 0.05 and 0.01 μm in sequence (smooth polishing is enough), and then ultrasonically cleaned in ultrapure water for 5 minutes to obtain A graphite substrate with a clean surface (about 1.5 cm in diameter); take it out and dry it naturally until there is no visible moisture on the surface to obtain an electrode substrate.

[0034] 2), using recombinant engineering bacteria to prepare DCM dehalogenase pure enzyme solution:

[0035] ① First, the recombinant engineering bacteria were prepared by using the DCM-degrading bacteria Methylobacterium H13 (CCTCC No: M 2010121), as follows:

[0036] The DCM dehalogenase gene was obtained by PCR cloning from the whole genome of the...

Embodiment 2

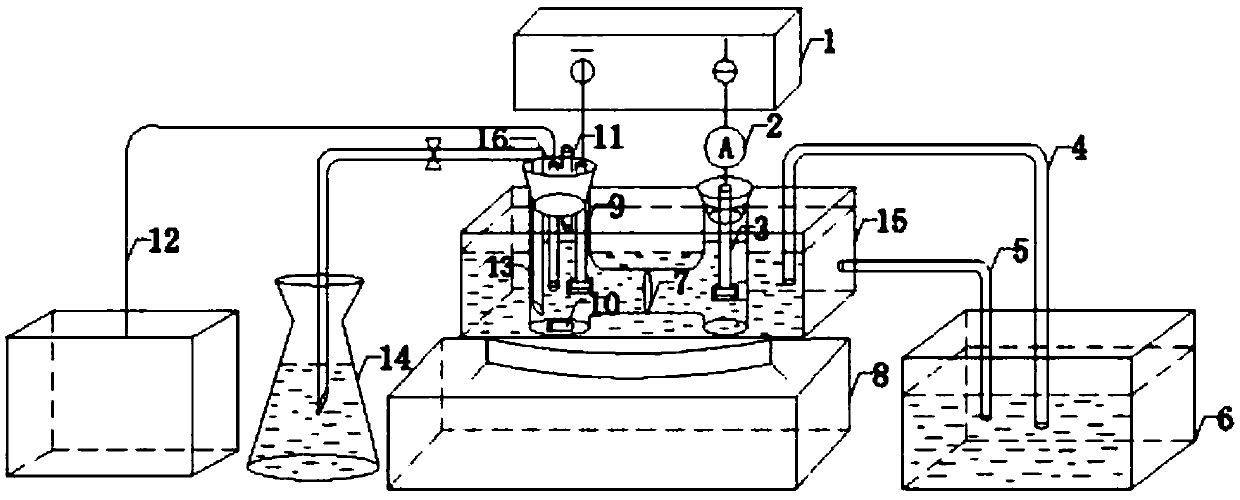

[0062] Embodiment 2, a kind of enzyme electric coupling dechlorination system device for processing DCM, such as figure 1 As shown, it consists of three parts: temperature control system, electrolytic reactor and pH adjustment system.

[0063] The electrolytic reactor includes a power source 1 and a reaction tank 15 , the power source 1 provides current for the electro-biological enzyme system, and the current is monitored in real time by the ammeter 2 . The reaction tank 15 is placed on the constant temperature magnetic stirrer 8, and the anion exchange membrane 7 is provided in the reaction tank 15, thereby the reaction tank 15 is separated to form a cathode electrolyzer and an anode electrolyzer, and a constant temperature magnetic force is provided in the cathode electrolyzer. The magnetic rotor 10 connected to the stirrer 8, under the drive of the constant temperature magnetic stirrer 8, the magnetic rotor 10 uniformly stirs the liquid in the reaction tank 15; Graphite e...

Embodiment 3

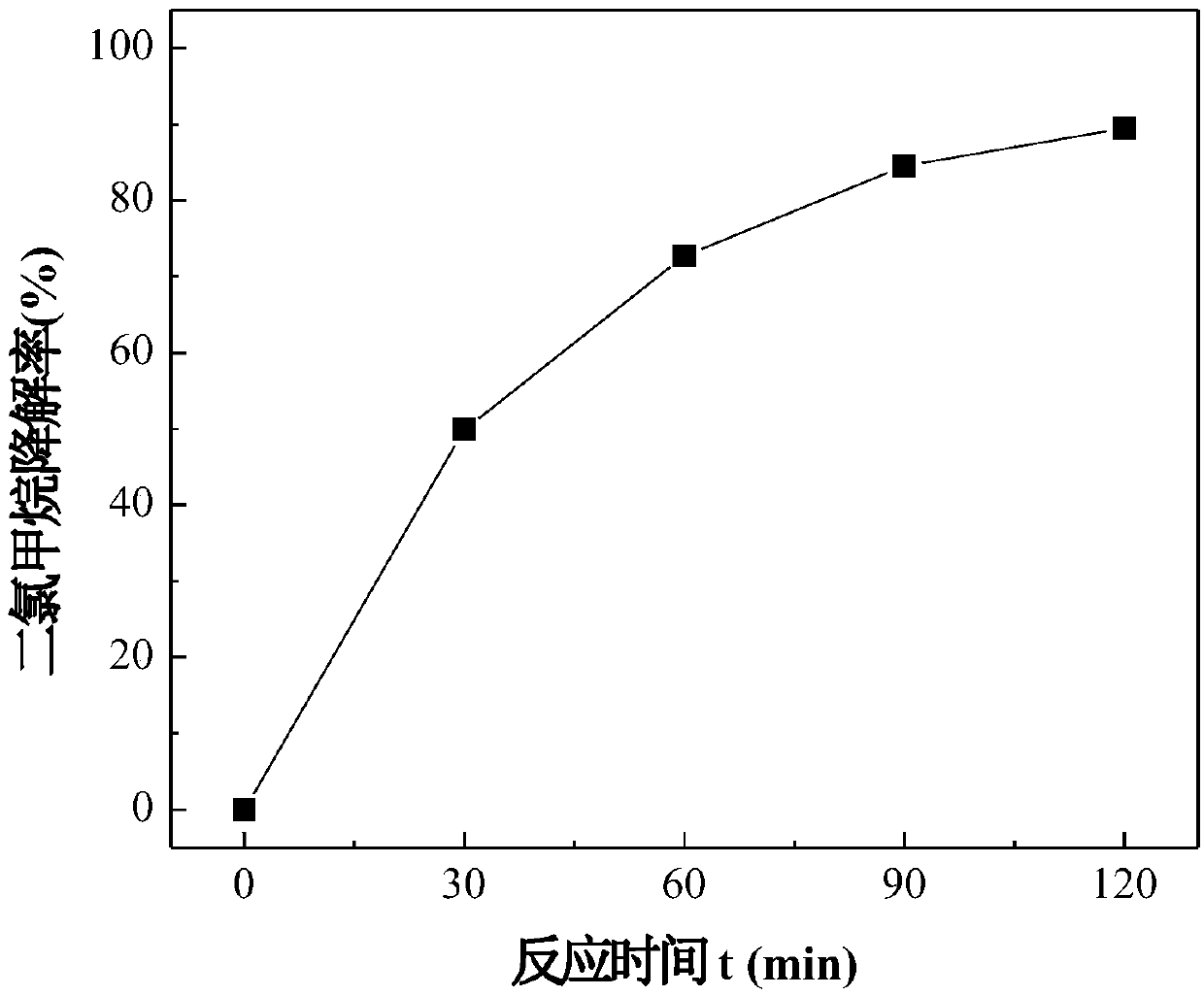

[0067] Embodiment 3, utilize the system device as described in embodiment 2, inject the 0.01M phosphate buffer solution of 100mL in the anode electrolyzer, inject the 0.01M phosphate buffer solution of 200mL in the cathode electrolyzer and add 3mg as coenzyme Reduced glutathione (GSH), 1.5 μ L DCM, adjust the pH to be 7 (regulate with a dilute sulfuric acid solution with a concentration of 20%), adjust the temperature of the water bath to be 35 ° C, and use a power supply control circuit with a current of 15 mA for constant current electrolysis 2h.

[0068] At this time, the dosage of DCM dechlorination enzyme is 28 mg; in the cathodic electrolyzer, the ratio of GSH to waste water containing DCM is 3 mg / 200 mL=15 mg / L.

[0069] Such as figure 2 As shown, the liquid in the cathode electrolyzer is detected, and the DCM concentration and degradation rate at different times are as follows in Table 1:

[0070] Table 1

[0071] Degradation time (min)

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com