Foamed ceramic for catalyst carriers and preparation and application methods thereof

A technology of catalyst carrier and foam ceramics, which is applied in the direction of catalyst carrier, catalyst activation/preparation, ceramic products, etc., and can solve the problems of low porosity and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

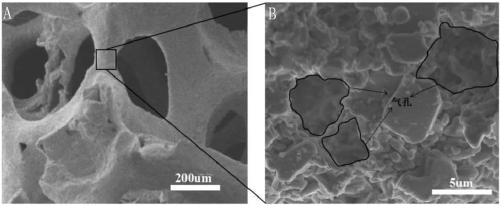

[0053] The embodiment of the present invention provides the preparation of 40PPI alumina foam ceramics loaded nickel-iron-copper flake catalyst, the specific steps are as follows:

[0054] (1) Cut the 40PPI polyurethane foam into the cuboid shape required for the experiment with a resistance wire cutting machine, and put it in an oven to dry at 80°C for 4 hours;

[0055] (2) At the same time, weigh 300g of alumina powder containing sintering aid and add 90g of deionized water to mix, then add 0.2g of carboxymethyl cellulose and 20g of PIMA microspheres, and ball mill for 4 hours to obtain a fully mixed slurry. The slurry was sieved to obtain the first pre-ceramic slurry, and 100 g of the first pre-ceramic slurry was weighed and 0.5 g of binder (PVA) was added and stirred evenly to obtain the first slurry-coated ceramic slurry. Dip the dried polyurethane foam into the ceramic slurry for the first paste, use a roller press to remove excess slurry on the polyurethane foam, and re...

Embodiment 2

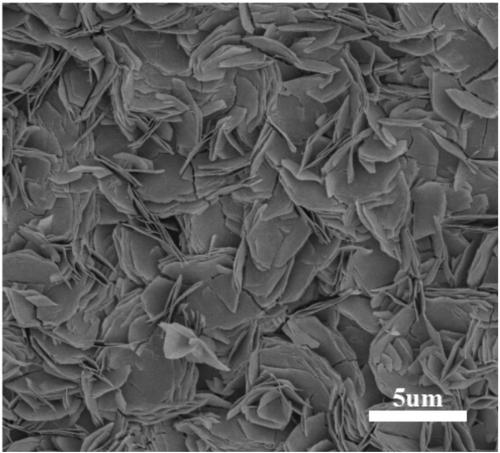

[0062] The embodiment of the present invention provides the preparation of 60PPI alumina foam ceramics loaded nickel-iron-copper flake catalyst, the specific steps are as follows:

[0063] (1) Cut the 60PPI polyurethane foam into cylinders required by the experiment with a resistance wire cutting machine, and put them in an oven to dry at 80°C for 4 hours;

[0064] (2) At the same time, weigh 400g of alumina powder containing sintering aids and add 120g of deionized water to mix, then add 0.3g of carboxymethyl cellulose and 30g of PIMA microspheres, and ball mill for 4 hours to obtain a fully mixed slurry. The slurry was sieved to obtain the first pre-ceramic slurry, and 100 g of the first pre-ceramic slurry was weighed and 0.5 g of binder (PVA) was added and stirred evenly to obtain the first slurry-coated ceramic slurry. Take out the dried polyurethane foam and dip it in the ceramic slurry for the first coating, use a roller press to remove excess slurry on the polyurethane ...

Embodiment 3

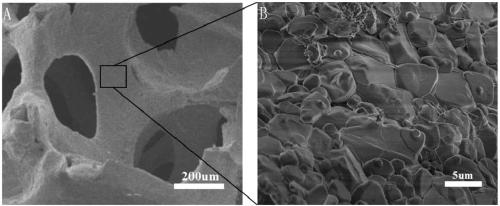

[0070] The embodiment of the present invention provides the preparation of 30PPI silicon carbide foam ceramics supported nickel-iron-copper flake catalyst, the specific steps are as follows:

[0071] (1) Cut the 30PPI polyurethane foam into the cuboid shape required for the experiment with a resistance wire cutting machine, and put it in an oven to dry at 80°C for 4 hours;

[0072] (2) Simultaneously weigh 400g of silicon carbide powder containing sintering aids and add 120g of deionized water to mix, then add 0.1g of carboxymethyl cellulose and 20g of PIMA microspheres, and ball mill for 4 hours to obtain a fully mixed slurry. The slurry was sieved to obtain the first pre-ceramic slurry, and 100 g of the first pre-ceramic slurry was weighed and 0.5 g of binder (PVA) was added and stirred evenly to obtain the first slurry-coated ceramic slurry. Take out the dried polyurethane foam and dip it in a small amount of ceramic slurry for the first paste, use a roller press to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com