Transformation method for improving economic cycle of hydrogenation device

A technology for economical operation and hydrogenation device, which is applied in the fields of hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of unsatisfactory oil-water separation effect, liquid with gas and gas with liquid, affecting the economic benefits of the device, etc. Achieve the effect of reducing the corrosion rate and the number of salt deposits, reducing waste water and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] After extensive and in-depth research, the inventors of the present application found that the overall transformation of the hydrogenation process has extremely high economic benefits.

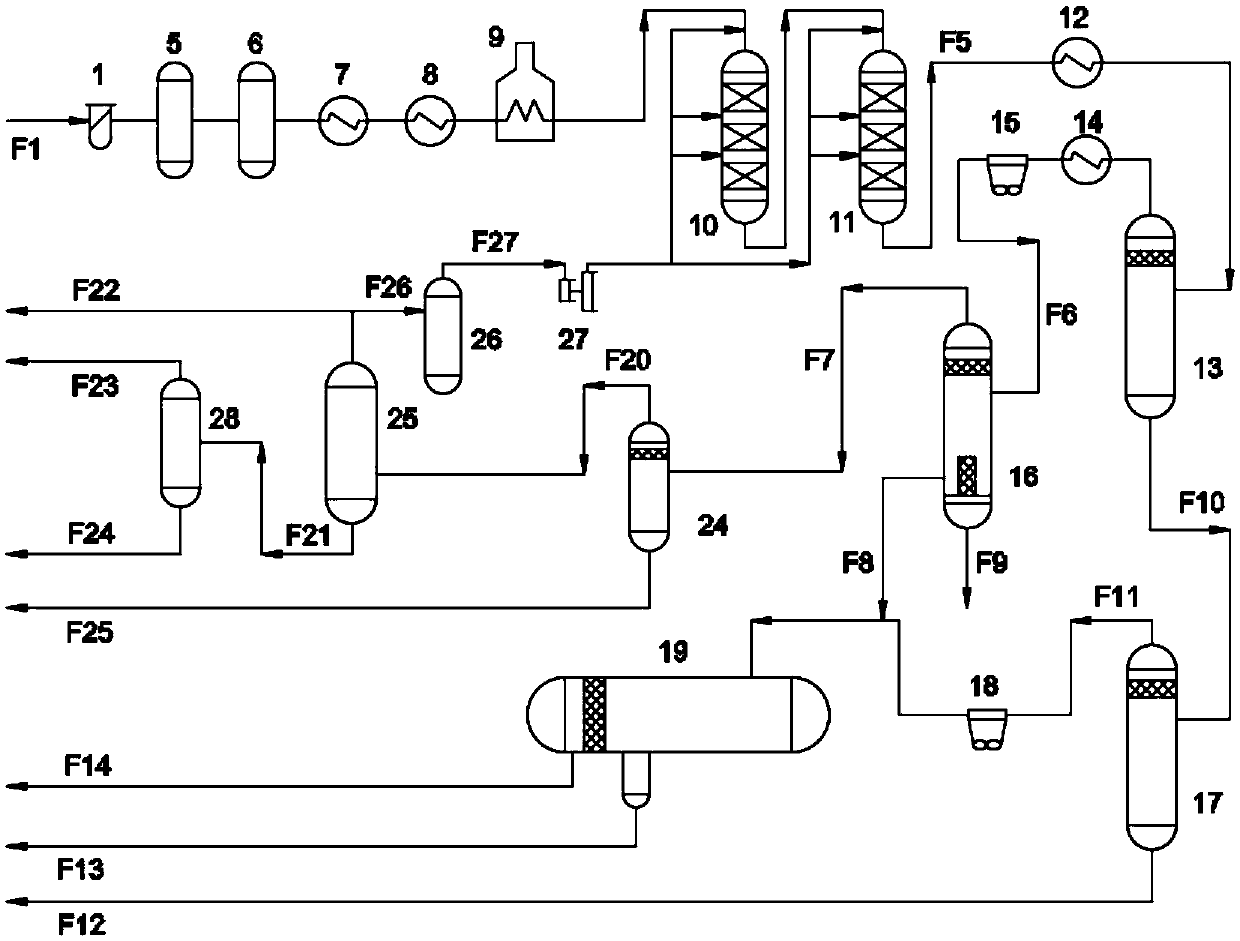

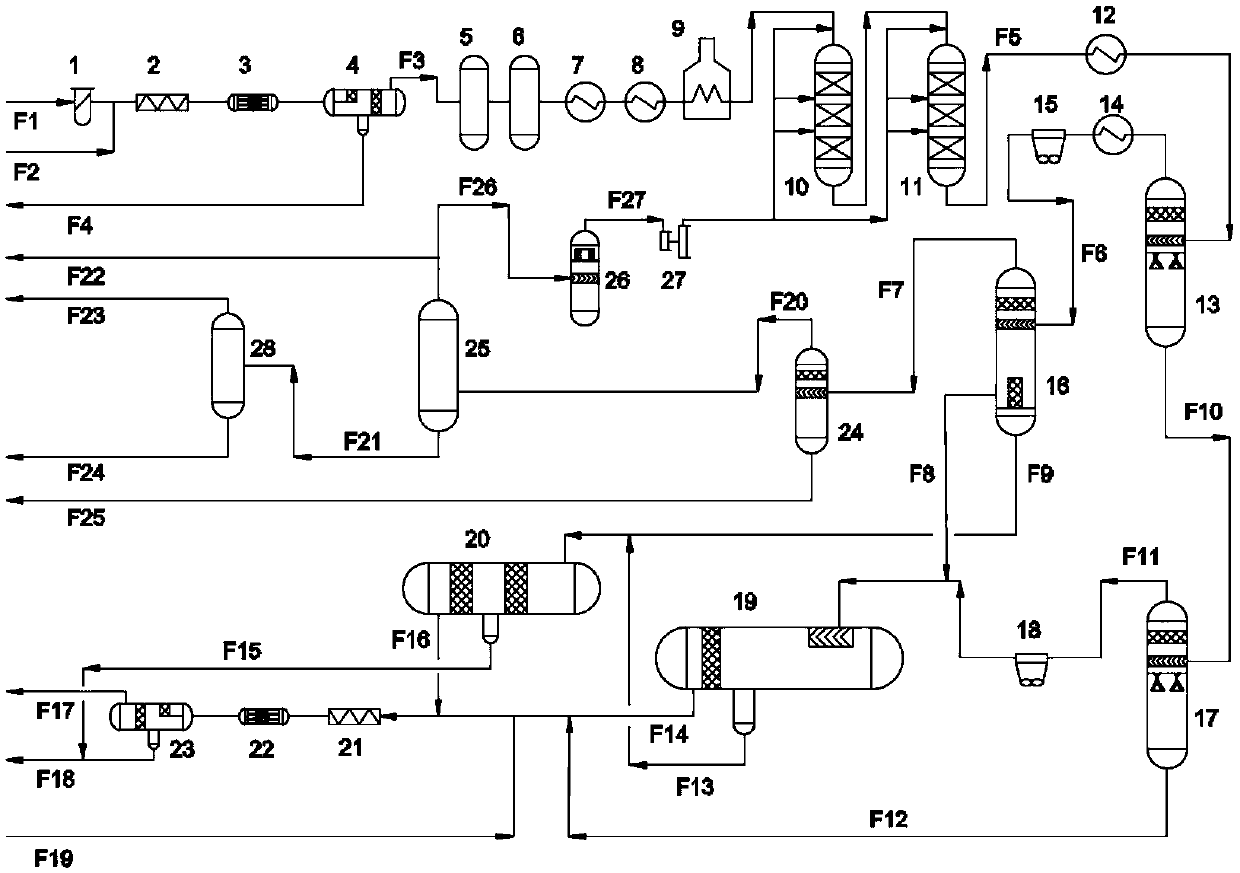

[0037] Such as figure 1 As shown in the 3 million tons / year original hydrogenation process flow chart of a petrochemical plant, due to the existence of various impurities such as sulfur and chlorine in the feed oil of the hydrogenation unit, the salt content of the circulating oil system at the top of the stripping tower is too high , with the increase of running time, the salt content continues to increase, and more salt crystals block the trays, air cooling, circulation pumps and pipelines, making it more likely to flush the tower, and the crystal particles increase the erosion and wear of the equipment, endangering Safe production and increased operational difficulty. At the same time, corrosion occurs in air cooling, booster pumps, pipelines, etc. in the stripping tower top reflux sy...

Embodiment 2

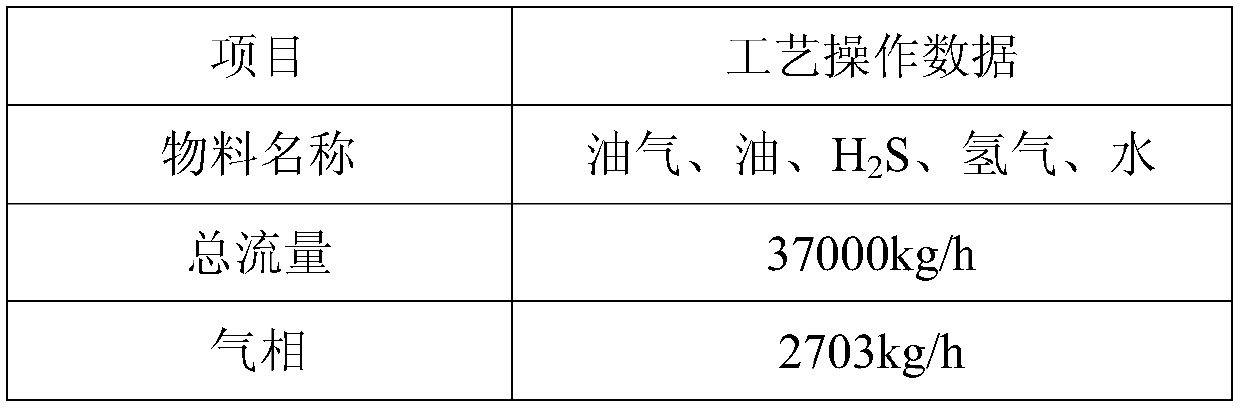

[0044] Table 1 shows the properties and operating parameters of the cold low-pressure separator of a hydrogenation unit in a refinery.

[0045] Table 1

[0046]

[0047]

[0048] According to the above operating parameters, the original cold low-pressure separator is designed as a gravity settling tank with a diameter of 2000mm and a tangential length of 5800mm for three-phase separation of oil, water and gas. After half a year of operation, it is found that the water content in the oil phase outlet often exceeds 2000ppm, and the water phase outlet The oil in the reclaimed water exceeds 1000ppm, and there is a problem of serious corrosion of the stripping tower and fractionating tower after passing through the cold low-pressure separator, which brings problems to the long-term and economical operation of the device. Therefore adopt technology of the present invention to transform this process:

[0049] General requirements for transformation: the water content in the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com