Liver and stomach protecting oil emulsion with function of dispelling effects of alcohol, and preparation method of oil emulsion

A technology for protecting stomach and oil emulsion, applied in the field of blending oil, can solve the problems of inability to cure alcohol well, large side effects, adverse consequences, etc., and achieve the effects of protecting human health, reducing liver damage, and promoting activation and regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

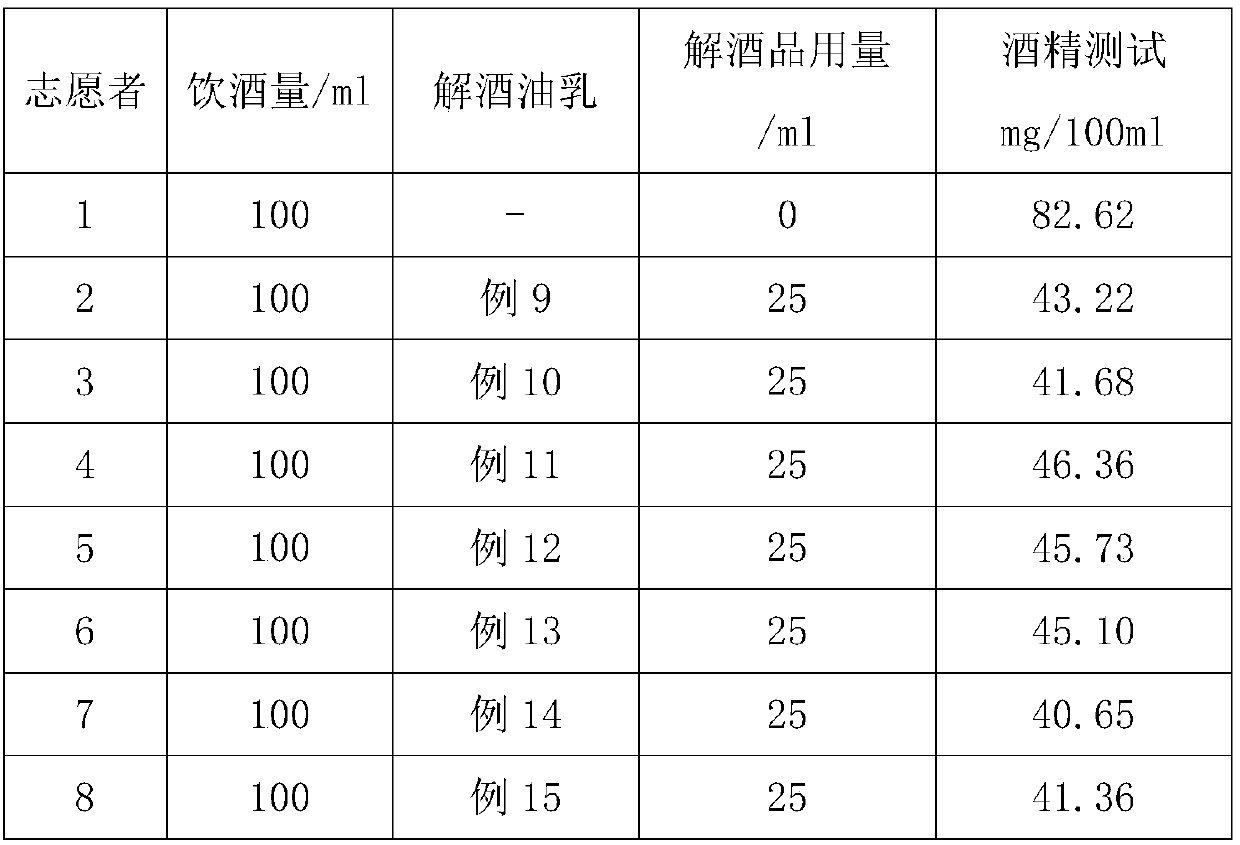

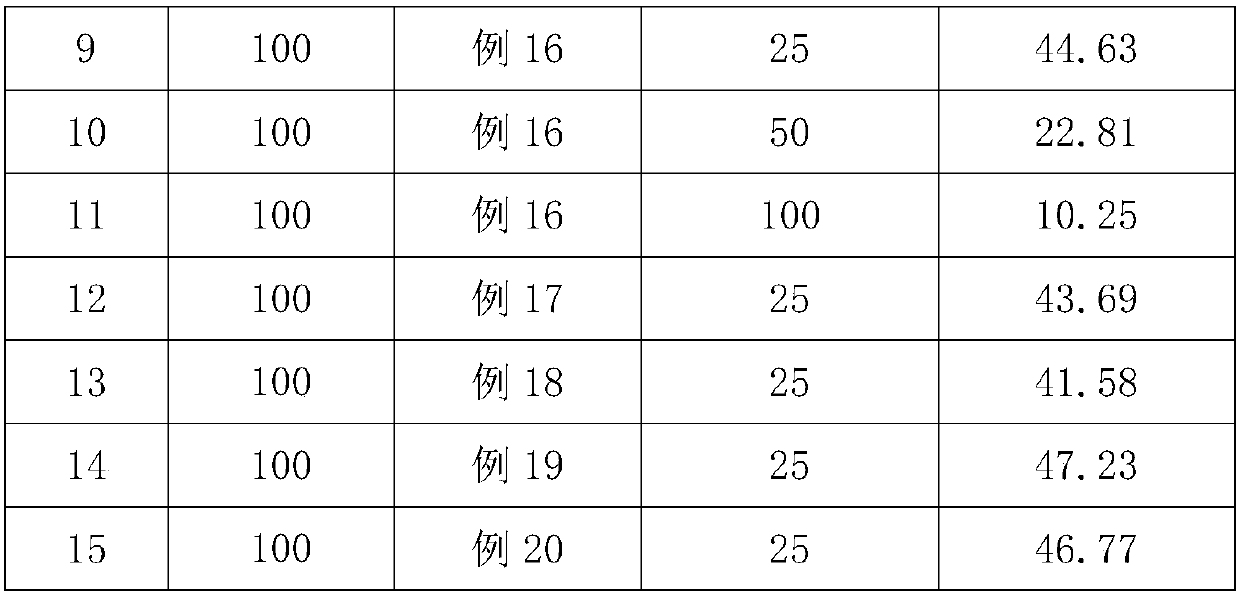

Examples

Embodiment 1

[0043] The camellia oleifera seed oil of embodiment 1 is prepared by the following method:

[0044] First, camellia seeds were dried, destoned, shelled and crushed and added to multistage separation supercritical CO 2 In the extraction kettle of the extraction equipment, adjust the extraction process conditions, the extraction temperature is 40°C, the extraction pressure is 33MPa, and the extraction time is 3.0h. After the extraction is completed, it enters the separation kettle for decompression separation of carbon dioxide and oil. The kettle temperature is 30°C, the separation kettle pressure is 6MPa, and the camellia seed oil crude oil is obtained from the separation kettle;

[0045] Then, refine the camellia seed oil crude oil: add the extracted camellia seed oil crude oil into a molecular distillation sample tank, adjust the molecular distillation process parameters, vacuum degree -0.5Pa, primary distillation temperature 100 ° C, two Stage distillation temperature 120°C...

Embodiment 2

[0047] The camellia oleifera seed oil of embodiment 2 is prepared by the following method:

[0048] First, camellia seeds were dried, destoned, shelled and crushed and added to multistage separation supercritical CO 2 In the extraction kettle of the extraction equipment, adjust the extraction process conditions, the extraction temperature is 50°C, the extraction pressure is 40MPa, and the extraction time is 2.0h. The kettle temperature is 40°C, the separation kettle pressure is 9MPa, and the camellia seed oil crude oil is obtained from the separation kettle;

[0049] Then, refine the camellia seed oil crude oil: add the extracted camellia seed oil crude oil into the molecular distillation sample tank, adjust the molecular distillation process parameters, vacuum degree 2Pa, primary distillation temperature 110°C, secondary distillation The temperature is 135°C, the three-stage distillation temperature is 165°C, and the speed of scraping film is 200r·min -1 , feed rate 35mL·mi...

Embodiment 3

[0051] The camellia oleifera seed oil of embodiment 3 is prepared by the following method:

[0052] First, camellia seeds were dried, destoned, shelled and crushed and added to multistage separation supercritical CO 2 In the extraction kettle of the extraction equipment, adjust the extraction process conditions, the extraction temperature is 60°C, the extraction pressure is 45MPa, and the extraction time is 1.0h. After the extraction is completed, it enters the separation kettle for decompression separation of carbon dioxide and oil. Still temperature 50 ℃, separating kettle pressure 15MPa, get camellia seed oil crude oil from separating kettle;

[0053] Then, refine the camellia seed oil crude oil: add the extracted camellia seed oil crude oil into the molecular distillation sample tank, adjust the molecular distillation process parameters, vacuum degree 5Pa, primary distillation temperature 120°C, secondary distillation The temperature is 150°C, the three-stage distillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com