Highly-dispersed quantum dot injection molding plastic grains and preparation method thereof

A high-dispersity, quantum dot technology, used in the field of display and lighting, can solve the problems of high storage environment requirements, fluorescence quenching inactivation, affecting optical effects, etc., to achieve good stability, stable performance, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

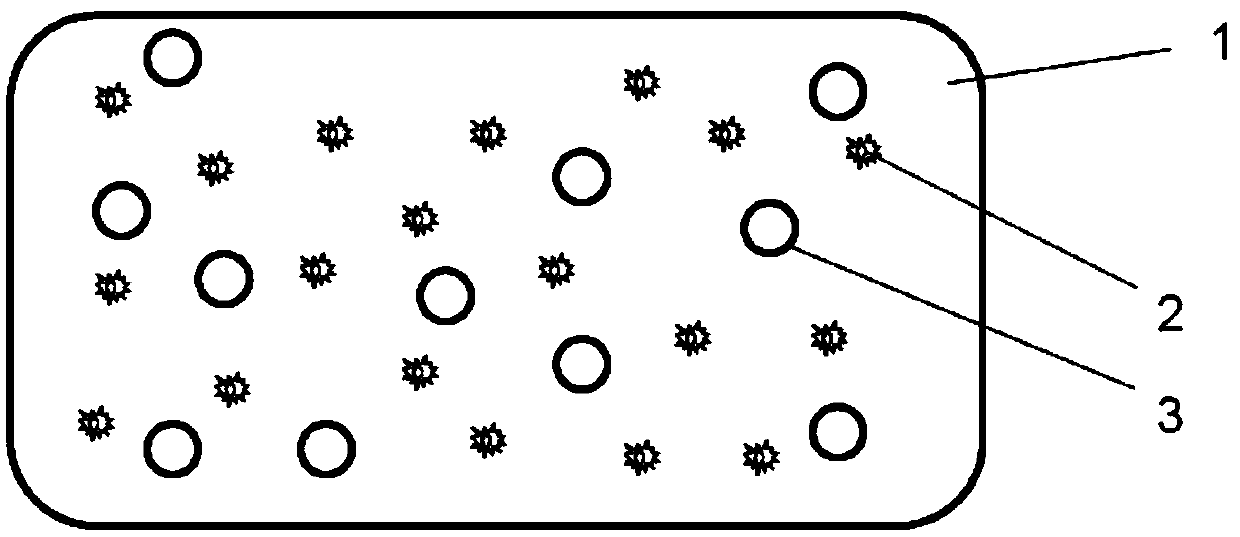

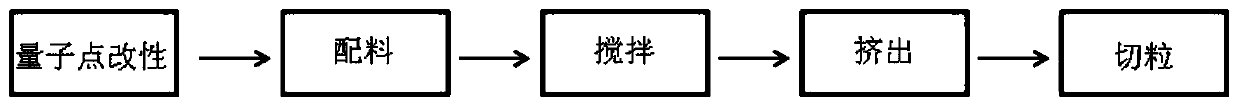

[0045] A kind of preparation method of high dispersion quantum dot 2 injection plastic rice, comprises the following steps:

[0046] Step 1: Surface modification of quantum dots 2, subjecting quantum dots 2 to high temperature resistance treatment;

[0047] Step 2: Composite ingredients, fully mix the surface-modified quantum dots 2 and dispersant 3, and then add them to the high polymer monomer for pre-polymerization;

[0048] Step 3: extrusion molding, extruding and cutting the pre-polymerized material into 2-injection plastic rice containing highly dispersed quantum dots.

[0049] The specific methods of the step one include:

[0050] Mix the quantum dots 2 with the high-temperature-resistant ligand, stir the mixture and place it in an ultrasonic instrument to fully disperse it;

[0051] The mixed liquid is then transferred to the flask and continuously stirred until the reaction stops;

[0052] Finally, transfer the mixture to a watch glass to evaporate excess solvent, an...

Embodiment 1

[0061] 1. Stearic acid and Al in equimolar ratio 2 o 3 Add it to a high-pressure reactor, and control the reaction at 200 ° C for 12 hours. After 12 hours, the reaction was stopped, and after cooling down to room temperature, it was transferred to an oven at 60°C to devolatilize part of the unreacted solvent to obtain a high-temperature-resistant ligand.

[0062] Add quantum dots with a mass ratio of 20% to a certain amount of high-temperature-resistant ligand and mix, stir the mixed solution and place it in an ultrasonic instrument to fully disperse it;

[0063] The mixed liquid is then transferred to the flask and continuously stirred until the reaction stops;

[0064] Finally, transfer the mixture to a watch glass to evaporate excess solvent, and bake until dry powder is obtained.

[0065] 2. Add 100 mg of quantum dot powder obtained after drying to 1 g of stearic acid amide, and stir and mix evenly;

[0066] 10kg of methyl methacrylate was pre-added in the reactor, and...

Embodiment 2

[0069] 1. Add stearic acid and SiC in an equimolar ratio to the autoclave, and control the reaction at 200°C for 12 hours. After 12 hours, the reaction was stopped, and after cooling down to room temperature, it was transferred to an oven at 60°C to devolatilize part of the unreacted solvent to obtain a high-temperature-resistant ligand.

[0070] Add quantum dots with a mass ratio of 20% to a certain amount of high-temperature-resistant ligand and mix, stir the mixed solution and place it in an ultrasonic instrument to fully disperse it;

[0071] The mixed liquid is then transferred to the flask and continuously stirred until the reaction stops;

[0072] Finally, transfer the mixture to a watch glass to evaporate excess solvent, and bake until dry powder is obtained.

[0073] 2. Add 250 mg of quantum dot powder obtained after drying to 25 g of erucamide, and stir and mix evenly;

[0074] 10kg of methyl methacrylate was pre-added into the reactor, and the mixture of quantum d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com