Acidic hole-adjusting agent used in circuit board hole metallization process, and preparation method of circuit board

A hole metallization and circuit board technology, applied in the field of PCB circuit board manufacturing, can solve the problems of non-compliance with environmental protection requirements, high waste water nitrogen and COD, difficulty in meeting the needs of high-performance circuit board manufacturing, etc., to achieve good electrical interconnection performance, Low COD and nitrogen content, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

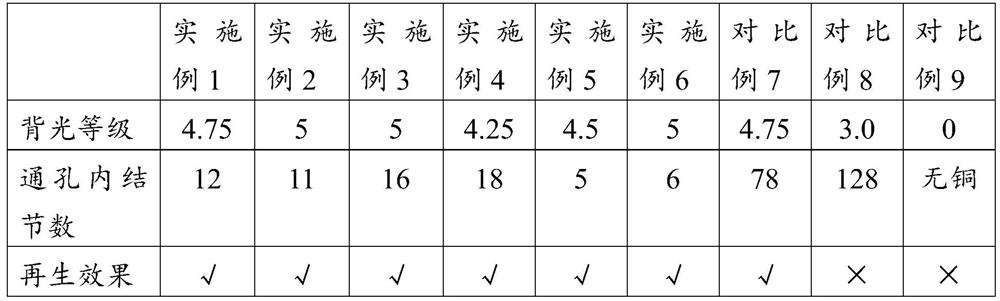

Examples

Embodiment 1

[0049] Prepare the acidic pore adjusting agent according to the method of aforementioned (1), and the concrete proportioning ratio is as follows:

[0050] Sulfuric acid 20g / L;

[0051] Glycolic acid 30.0g / L;

[0052] Hydroxyethylene diphosphonic acid 10.0g / L;

[0053] TX-10 5.0g / L;

[0054] Diethylenetriamine and acrylamide 1:1 hyperbranched copolymer 1.5g / L;

[0055] Deionized water balance.

[0056] Heat the prepared pore adjusting agent to 50°C for later use. The through-hole copper-clad laminate with a thickness of 2.0mm to be tested is processed according to the hole metallization process of the aforementioned steps a~i. After the copper plating is completed, the sample is dried for test evaluation, and the obtained results are recorded as 1-1.

Embodiment 2

[0058] Prepare the acidic pore adjusting agent according to the method of aforementioned (1), and the concrete proportioning ratio is as follows:

[0059] Hydrochloric acid 30g / L;

[0060] Citric acid 150.0g / L;

[0061] Hydroxyethylene diphosphonic acid 30.0g / L;

[0062] Triethylenetetramine and acrylamide 1:1.5 hyperbranched copolymer 5.0g / L;

[0063] TTX-100 2.0g / L;

[0064] Deionized water balance.

[0065] Heat the prepared pore adjusting agent to 50°C for later use. The through-hole copper-clad laminate with a thickness of 2.0mm to be tested is processed according to the hole metallization process of the aforementioned steps a~i. After the copper plating is completed, the sample is dried for test evaluation, and the obtained results are recorded as 2-1.

Embodiment 3

[0067] Prepare the acidic pore adjusting agent according to the method of aforementioned (1), and the concrete proportioning ratio is as follows:

[0068] Phosphoric acid 60g / L;

[0069] Methanesulfonic acid 100.0g / L;

[0070] Amino trimethylene phosphonic acid 30.0g / L;

[0071] Triethylenetetramine and methyl acrylate 2:5 hyperbranched copolymer 10.0g / L;

[0072] NP-10 4.0g / L;

[0073] Deionized water balance.

[0074] Heat the prepared pore adjusting agent to 50°C for later use. The through-hole copper-clad laminate with a thickness of 2.0 mm to be tested is processed according to the hole metallization process of the aforementioned steps a~i. After the copper plating is completed, the sample is dried for test evaluation, and the obtained results are recorded as 3-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com