Method for processing inferior diesel oil raw material through moving bed hydrogenation

A low-quality diesel oil and hydroprocessing technology, which is applied in the fields of hydroprocessing technology, petroleum industry, and hydrocarbon oil treatment, can solve the problems of short service life of the catalyst, insufficient contact of oil and gas, and low yield of product oil, etc., to achieve flexible The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

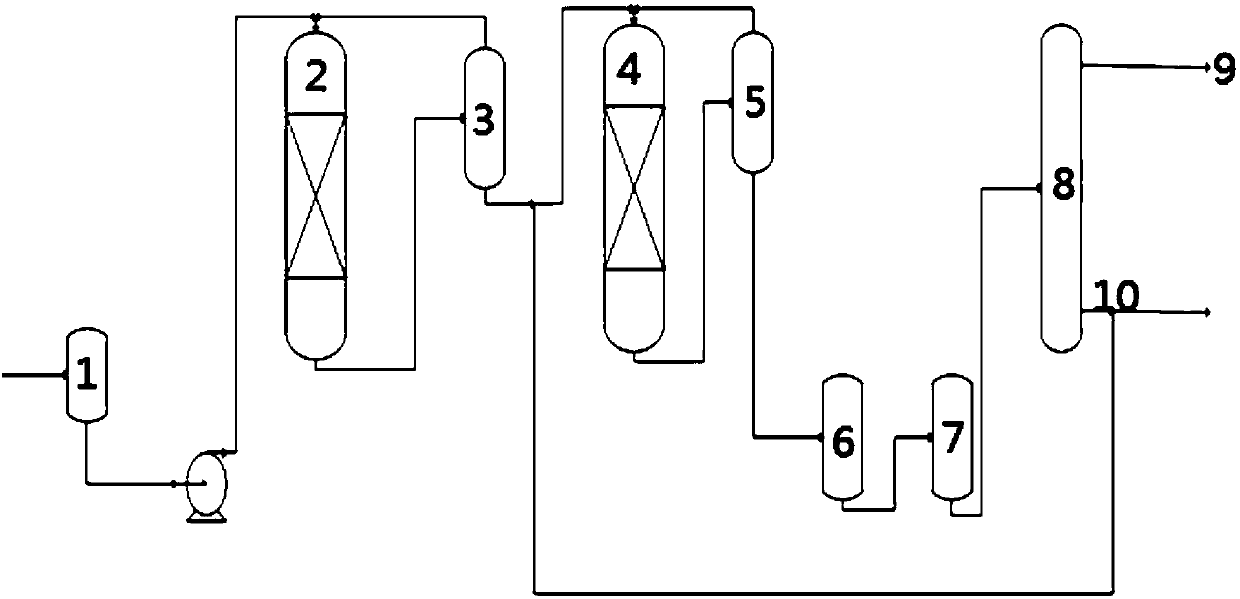

[0072] (1) In the presence of hydrogen, the inferior diesel feedstock from the feedstock buffer tank 1 is introduced into the moving bed hydrotreating reaction unit 2 to carry out the first contact reaction with the hydrotreating catalyst contained therein;

[0073] (2) All the materials in the moving bed hydrofining reaction unit 2 after the first contact reaction are drawn out, and then separated in the first separation device 3 in the moving bed hydrofinishing reaction unit 2 after the first contact reaction material, and returning the separated hydrotreating catalyst to the moving bed hydrotreating reaction unit 2;

[0074] (3) introducing hydrogen and the remaining material from which the hydrorefining catalyst has been separated in step (2) into the moving bed hydro-upgrading reaction unit 4 to carry out a second contact reaction with the hydro-upgrading catalyst contained therein;

[0075] (4) All the materials in the moving bed hydrogenation upgrading reaction unit 4 a...

preparation example 1

[0084] Taking by weighing dry basis is that 142.9 grams of pseudo-boehmite (Catalyst Changling Branch) of 70% by weight and 117.6 grams of USY type zeolite (Catalyst Changling Branch of Catalyst Changling Branch) of 85% by weight are mixed Uniformly, 8.2% by weight of aluminum sol was added to form a slurry with stirring, and spray-dried to prepare microspheres with an average particle diameter of 200 μm to obtain catalyst carrier Z1.

[0085] Take 100 g of carrier Z1 and use 85 ml each containing MoO3 (268.1 g / L), P 2 o 5 (44.7 g / L) molybdenum trioxide and phosphoric acid mixed solution impregnated for 1 hour, dried at 120° C. for 2 hours, and calcined at 550° C. for 4 hours to obtain catalyst C1. Based on the total weight of the catalyst, the composition of the catalyst C1 after calcination is shown in Table 4. The content of active components was determined by X-fluorescence method (the same below).

preparation example 2

[0087] Take 100.0 grams of USY type zeolite (catalyst Changling branch company, unit cell constant 24.43 angstroms) and 9.5 grams of molybdenum trioxide that are 85% by weight on a dry basis and grind and mix uniformly in a mortar; then place the tube furnace constant temperature zone, Under hydrogen and water vapor atmosphere (hydrogen: water vapor volume ratio = 30:1), treated at 450°C for 4 hours to obtain Mo-modified USY molecular sieve MoUSY1 prepared by solid-phase exchange method.

[0088] Weigh 142.9 grams of pseudo-boehmite (Catalyst Changling Branch) and MoUSY1 (122.4 grams) that are 70% by weight on a dry basis and mix well, add 8.2% by weight of aluminum sol to stir to form a slurry, and spray dry to prepare an average Microspheres with a particle diameter of 200 μm were obtained to obtain catalyst carrier Z2.

[0089] Take carrier 100g Z2, use 83ml respectively containing MoO 3 (83.8 g / L), P 2 o 5 (27.7 g / L) molybdenum trioxide and phosphoric acid mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com