A kind of solid antibacterial hard coating of space mechanism component and preparation method thereof

A technology of mechanical parts and hard film layers, which is applied in the field of solid antibacterial hard coating products of space mechanism parts and its preparation, can solve the problems of high brittleness and low bonding strength, achieve easy regulation, improve coating bonding force, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

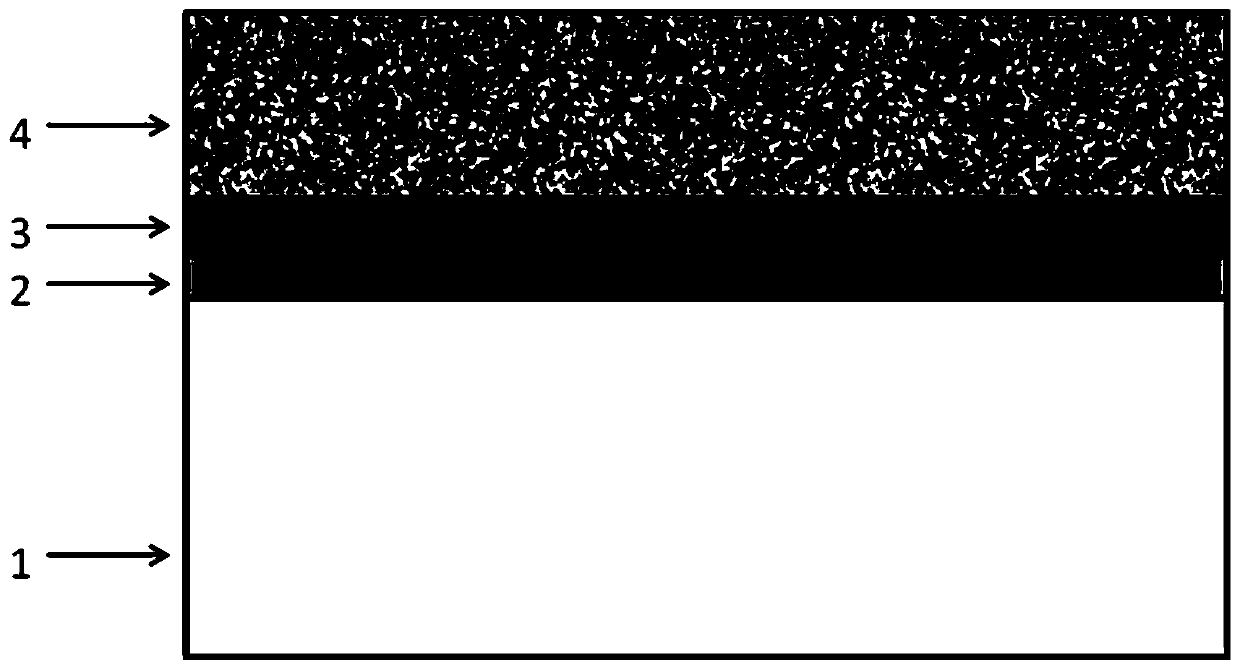

[0025] The structural representation of the antibacterial hard coating product prepared by the present invention, see figure 1 ; Wherein 1-substrate, 2-bonding layer (Ti), 3-transition layer (TiN), 4-functional layer (TiAlZrN-Ag).

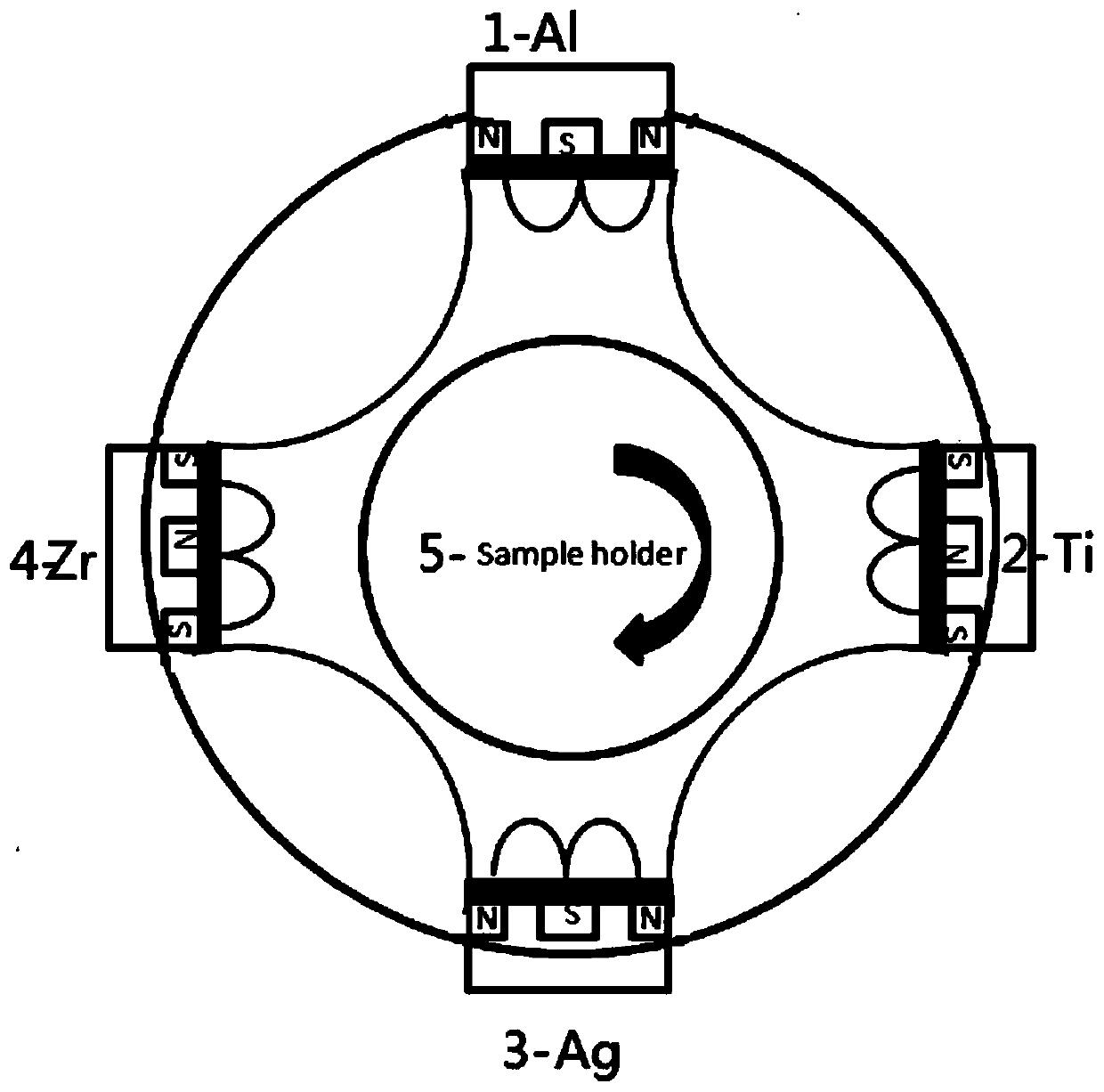

[0026] The closed-field unbalanced magnetron sputtering equipment structure schematic diagram adopted in the reactive magnetron sputtering technology of the present invention, see figure 2 ; Wherein 1-Al target, 2-Ti target, 3-Ag target, 4-Zr target, 5-plated piece platform.

[0027] The solid antibacterial hard coating product for space mechanism components includes a Ti / TiN / (TiAlZrN-Ag) nanocomposite multilayer film with a substrate of TC4 titanium alloy and a thickness of 2 μm. The thickness of the bonding layer is 50nm, the thickness of the transition layer is 200nm, and the thickness of the functional layer is 1.75μm.

[0028] The preparation method of the solid antibacterial hard coating product of the space mechanism component is as follo...

Embodiment 2

[0037] The difference between Implementation 2 and Example 1 is that the Al and Zr target currents in step 4 in Example 1 are adjusted to 0.5A, the Ag target currents are adjusted to 0.8A, and the preparation time of the TiAlZrN-Ag film layer is shortened to 1.5h, keeping The total thickness of the film layer is consistent, and other steps are the same as in Example 1.

[0038] The structural representation of the antibacterial hard coating product prepared by the present invention, see figure 1 ; Wherein 1-substrate, 2-bonding layer (Ti), 3-transition layer (TiN), 4-functional layer (TiAlZrN-Ag).

[0039] The closed-field unbalanced magnetron sputtering equipment structure schematic diagram adopted in the reactive magnetron sputtering technology of the present invention, see figure 2 ; Wherein 1-Al target, 2-Ti target, 3-Ag target, 4-Zr target, 5-plated piece platform.

[0040] The solid antibacterial hard coating product for space mechanism components includes a Ti / TiN / (T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com