A kind of preparation method of gypsum whiskers

A gypsum whisker and fine powder technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of mountain vegetation destruction, high resource consumption and high preparation cost, achieve smooth surface and improve utilization efficiency , the effect of good microscopic morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

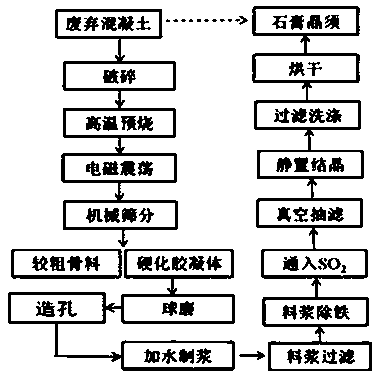

Method used

Image

Examples

Embodiment 1

[0037] 1) Select waste concrete from construction waste, crush it with a small hammer crusher and control the particle size of the discharged particles to ≤10mm, then put the crushed particles into a corundum crucible and put them in a box-type resistance furnace at 500°C Carry out pre-burning for 20 minutes, take it out after the furnace temperature is lowered to below 100°C, and after cooling to room temperature, shake the pre-burned particles in an electromagnetic vibrating pulverizer for 3-10 seconds, and pour them into a 125-mesh square hole sieve after shaking and separating. Sieve, and then ball mill the fine particles collected under the sieve, and control the discharge particle size of the ball mill to be less than 45 μm, that is, to obtain hardened gel fine powder.

[0038] 2) Mix the hardened gel fine powder and carbon powder obtained in step 1) according to the mass ratio of 100:10, and then mix it in a high-speed mixer at a speed of 200-500rpm for 20-30min, after t...

Embodiment 2

[0044] 1) Select waste concrete from construction waste, use a small hammer crusher to crush and control the particle size of the discharged particles to ≤10mm, then put the crushed particles into a corundum crucible and put them in a box-type resistance furnace at 550°C Carry out pre-burning for 20 minutes, take it out after the furnace temperature is lowered to below 100°C, and after cooling to room temperature, shake the pre-burned particles in an electromagnetic vibrating pulverizer for 3-10 seconds, and pour them into a 200-mesh square hole sieve after shaking and separating. Sieve, and then ball mill the fine particles collected under the sieve, and control the discharge particle size of the ball mill to be less than 45 μm, that is, to obtain hardened gel fine powder.

[0045] 2) Mix the hardened gel fine powder obtained in step 1) with carbon powder according to the mass ratio of 150:10, and then mix it in a high-speed mixer at a speed of 200-500rpm for 20-30min, after t...

Embodiment 3

[0051] 1) Select waste concrete from construction waste, crush it with a small hammer crusher and control the particle size of the discharged particles to ≤10mm, then put the crushed particles into a corundum crucible and put them in a box-type resistance furnace at 300°C Carry out pre-burning for 20 minutes, take it out after the furnace temperature is lowered to below 100°C, and after cooling to room temperature, shake the pre-burned particles in an electromagnetic vibrating pulverizer for 3-10 seconds, and pour them into a 325-mesh square hole sieve after shaking and separating. Sieve, and then ball mill the fine particles collected under the sieve, and control the discharge particle size of the ball mill to be less than 45 μm, that is, the hardened gel powder fine powder is obtained.

[0052] 2) Mix the hardened gel fine powder and carbon powder obtained in step 1) according to the mass ratio of 200:10, and then mix it in a high-speed mixer at a speed of 200-500rpm for 20-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com