Method of manufacturing semiconductor device

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of lack of convenience of sacrificial films, and achieve the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

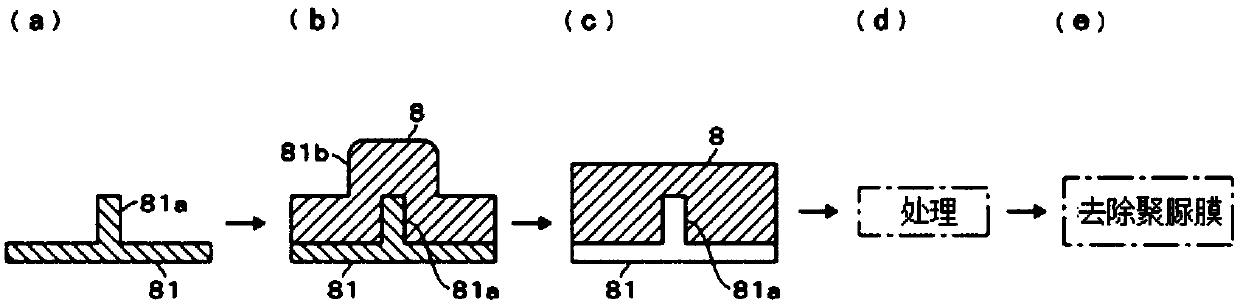

[0072] The first embodiment is a method of forming a sacrificial film on a level difference substrate having a level difference formed on the surface, for example, a silicon wafer subjected to predetermined film formation processing and etching, and an example thereof is shown in figure 1 . figure 1 In the example, the substrate 81 ( figure 1 (a)) Polyurea film 8 ( figure 1 (b)).

[0073] For polyurea membranes, for example, such as Figure 5 As shown, it can be produced by copolymerization using isocyanate and amine. R is, for example, an alkyl group (straight-chain or cyclic alkyl) or an aryl group, and n is an integer of 2 or more.

[0074] As the isocyanate, for example, an alicyclic compound, an aliphatic compound, an aromatic compound or the like can be used. As alicyclic compounds, for example, such as Figure 6 As shown in (a), 1,3-bis(isocyanatomethyl)cyclohexane (H6XDI) can be used. In addition, as aliphatic compounds, for example, such as Figure 6 As sh...

no. 2 Embodiment approach >

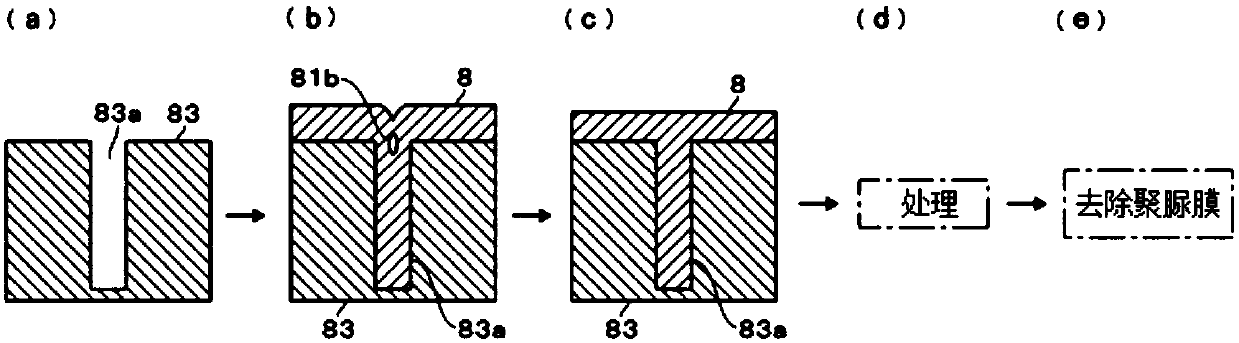

[0096] The second embodiment is a method of forming a sacrificial film of a protective film on a surface having a concave portion such as a narrow and deep hole or groove, and an example thereof is shown in image 3 . image 3 In an example, the substrate 83 ( image 3 (a)) Polyurea film 8 ( image 3 (b)). The hole diameter or groove width of the concave portion 83 a is, for example, 100 nm to 10 nm, and the aspect ratio is, for example, 2 or more. When the polyurea film 8 is formed on the substrate 83 having such a concave portion 83a, before the polyurea film 8 is completely embedded in the concave portion 83a, the entrance of the concave portion 83a is blocked, and as a result, voids (voids or seams) are formed in the concave portion 83a. ) 83b. In addition, depressions are formed on the surface of the polyurea film 8 at positions corresponding to the recesses 83 a.

[0097] If the void 83b is formed in the concave portion 83a, the polyurea film 8 may not be able to fu...

no. 3 Embodiment approach >

[0102] The third embodiment is a method of permeating a polyurea film into a porous low dielectric constant film to form a sacrificial film as a protective film, an example of which is shown in Figure 4 . Figure 4 In the example described in the first embodiment, for example, the low dielectric constant film 20 ( Figure 4 (a)) upper film-forming polyurea film 8 ( Figure 4 (b)). The SiOC film is formed, for example, by CVD by plasmating DEMS (diethoxymethylsilane). For the film formation of the polyurea film 8, for example, when isocyanate gas and amine gas are alternately supplied into the low dielectric constant film 20, the gas permeates into the pores 21 in the low dielectric constant film 20 to form a polyurea film. A state where the film 8 is laminated on the low dielectric constant film 20 while polyurea (indicated by a blackened portion) enters the hole portion 21 .

[0103] At this time, the embedding of polyurea into the hole 21 is insufficient, that is, a voi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com