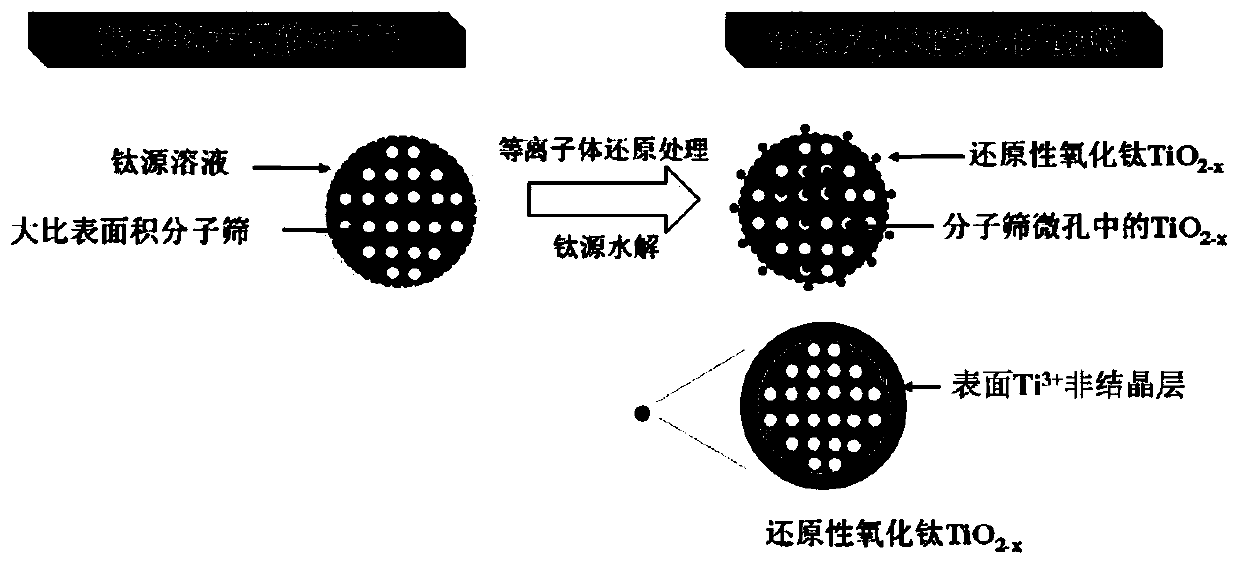

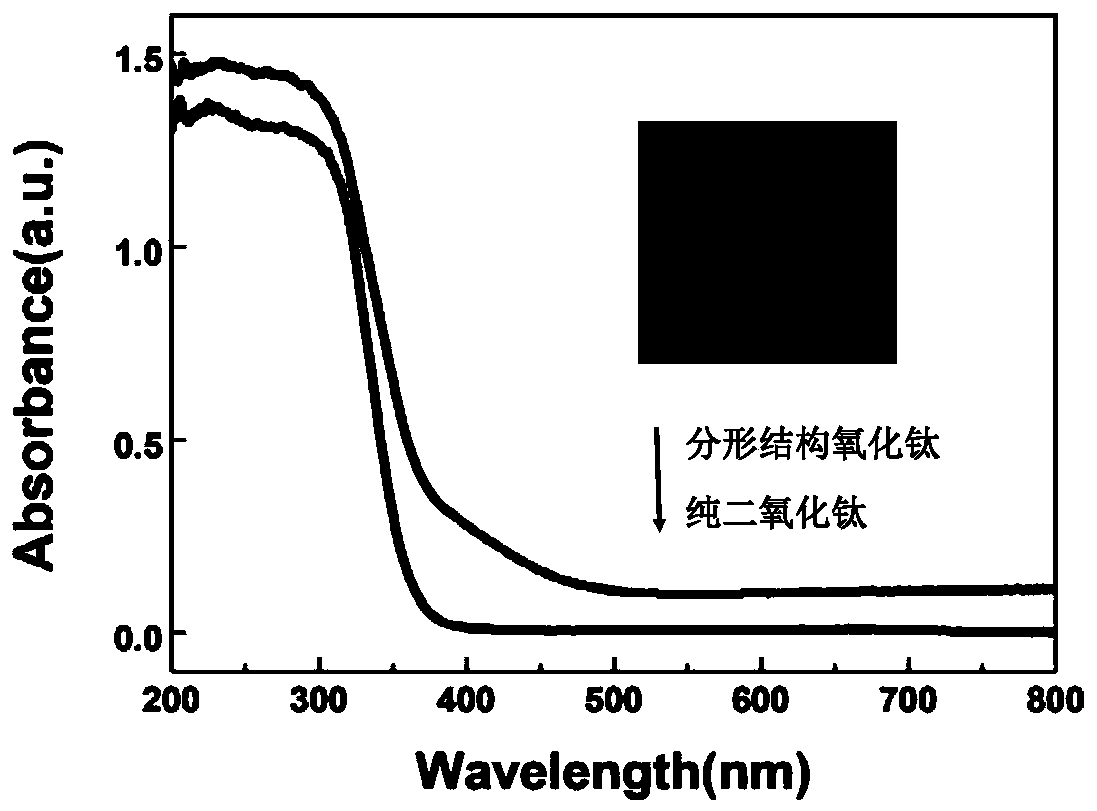

Preparation method for titanium oxide with fractal structure

A fractal structure and titanium oxide technology, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of chemical reagent environmental pollution, energy waste, and complicated treatment process, and achieve environmental friendliness and low cost. The effect of low cost and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The molecular sieve with a silicon-aluminum ratio of 30 was used as a raw material to prepare a fractal structure titania photocatalyst.

[0030] Add 10 ml of tetrabutyl titanate into 50 ml of absolute ethanol, and stir evenly to obtain a titanium ion solution. Drop 2 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Fully mix 10 g of molecular sieves with a silicon-aluminum ratio of 30, an electrolyte solution, and a titanium ion solution to obtain a precursor liquid. Drop 7 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

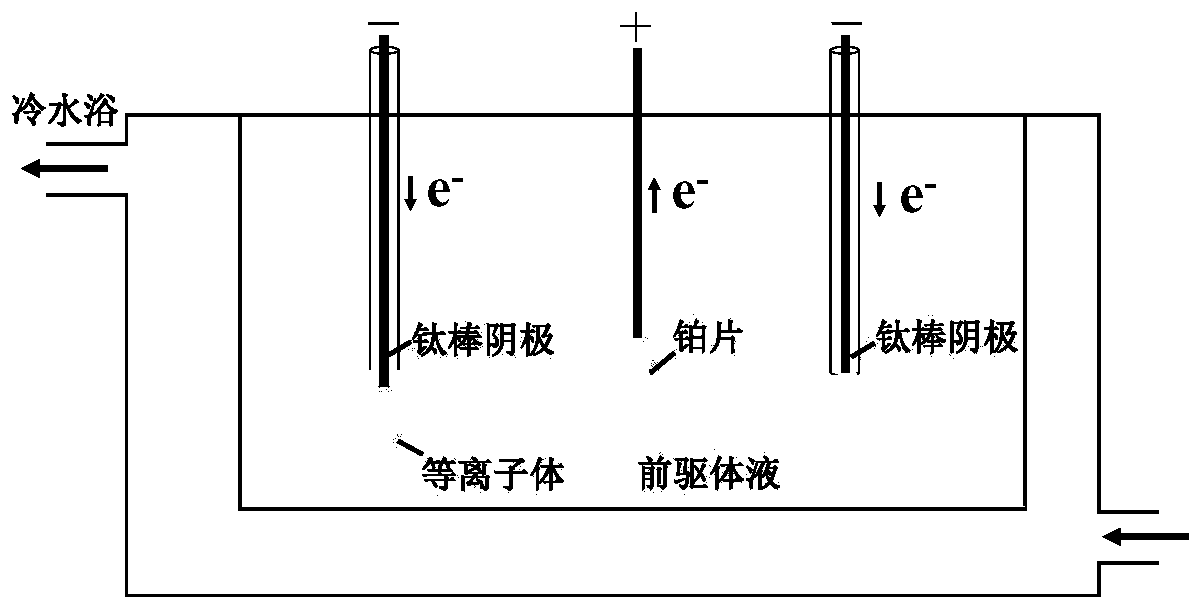

[0031] Such as figure 2 As shown, two rod-shaped titanium cathodes are symmetrically placed on both sides of the platinum sheet anode to assemble a parallel discharge system. The two rod-shaped titanium cathodes used are both 4 mm in diameter and 20 cm in length. The two rod-shaped cathodes are inserted into the corundum...

Embodiment 2

[0036] The molecular sieve with a silicon-aluminum ratio of 60 was used as a raw material to prepare a fractal structure titania photocatalyst.

[0037] Add 10 ml of tetrabutyl titanate into 50 ml of absolute ethanol, and stir evenly to obtain a titanium ion solution. Drop 2 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Fully mix 10 g of molecular sieves with a silicon-aluminum ratio of 60, an electrolyte solution, and a titanium ion solution to obtain a precursor liquid. Drop 7 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

[0038] Such as figure 2 As shown, two rod-shaped titanium cathodes are symmetrically placed on both sides of the platinum sheet anode to assemble a parallel discharge system. The two rod-shaped titanium cathodes used are both 4 mm in diameter and 20 cm in length. The two rod-shaped cathodes are both inserted into the cor...

Embodiment 3

[0043] The molecular sieve with a silicon-aluminum ratio of 300 was used as a raw material to prepare a fractal structure titania photocatalyst.

[0044] Add 10 ml of tetrabutyl titanate into 50 ml of absolute ethanol, and stir evenly to obtain a titanium ion solution. Drop 2 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Fully mix 10 g of molecular sieves with a silicon-aluminum ratio of 300, an electrolyte solution, and a titanium ion solution to obtain a precursor liquid. Drop 7 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

[0045] Such as figure 2 As shown, two rod-shaped titanium cathodes are symmetrically placed on both sides of the platinum sheet anode to assemble a parallel discharge system. The two rod-shaped titanium cathodes used are both 4 mm in diameter and 20 cm in length. The two rod-shaped cathodes are both inserted into the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com