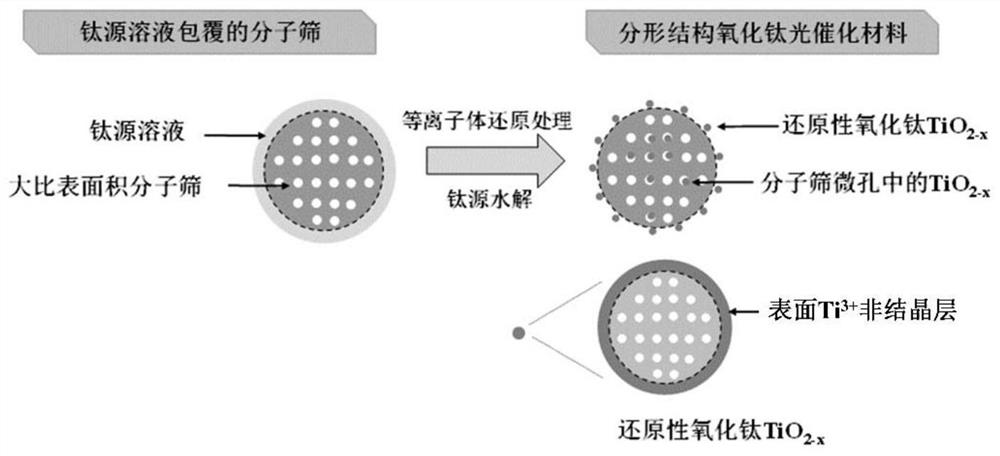

A kind of preparation method of fractal structure titanium oxide

A fractal structure, titanium oxide technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of complex treatment process, energy waste, environmental pollution of chemical reagents, etc., to achieve simple process operation, Low cost and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

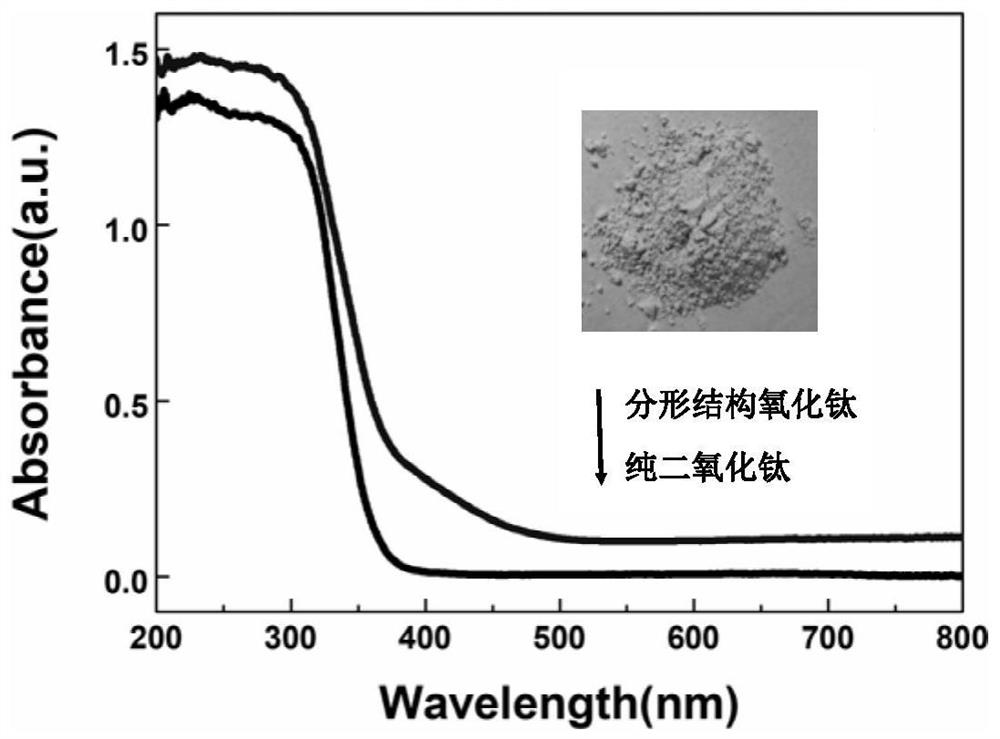

[0029] The molecular sieve with a silicon-aluminum ratio of 30 was used as a raw material to prepare a fractal structure titania photocatalyst.

[0030] Add 10 ml of tetrabutyl titanate into 50 ml of absolute ethanol, and stir evenly to obtain a titanium ion solution. Drop 2 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Fully mix 10 g of molecular sieves with a silicon-aluminum ratio of 30, an electrolyte solution, and a titanium ion solution to obtain a precursor liquid. Drop 7 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

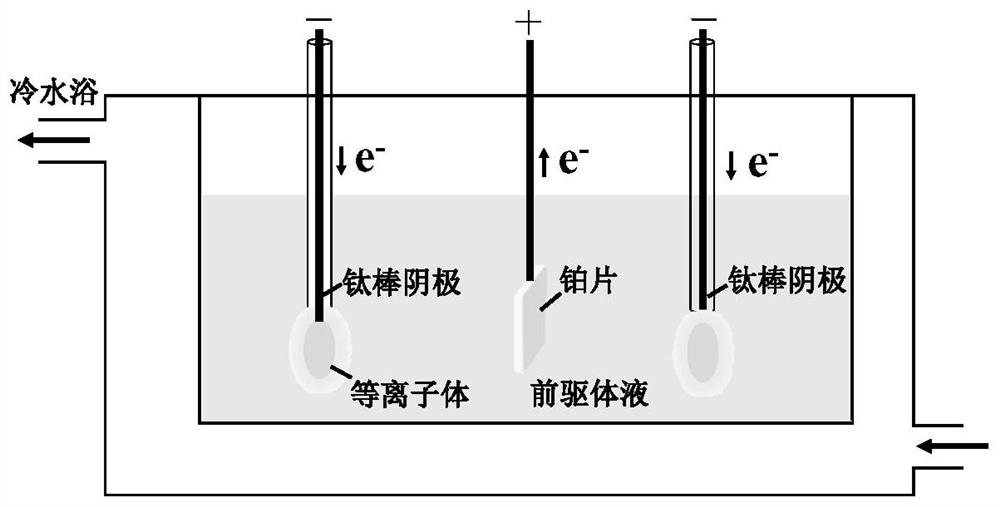

[0031] Such as figure 2 As shown, two rod-shaped titanium cathodes are symmetrically placed on both sides of the platinum sheet anode to assemble a parallel discharge system. The two rod-shaped titanium cathodes used are both 4 mm in diameter and 20 cm in length. The two rod-shaped cathodes are inserted into the corundum...

Embodiment 2

[0036] The molecular sieve with a silicon-aluminum ratio of 60 was used as a raw material to prepare a fractal structure titania photocatalyst.

[0037] Add 10 ml of tetrabutyl titanate into 50 ml of absolute ethanol, and stir evenly to obtain a titanium ion solution. Drop 2 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Fully mix 10 g of molecular sieves with a silicon-aluminum ratio of 60, an electrolyte solution, and a titanium ion solution to obtain a precursor liquid. Drop 7 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

[0038] Such as figure 2 As shown, two rod-shaped titanium cathodes are symmetrically placed on both sides of the platinum sheet anode to assemble a parallel discharge system. The two rod-shaped titanium cathodes used are both 4 mm in diameter and 20 cm in length. The two rod-shaped cathodes are both inserted into the cor...

Embodiment 3

[0043] The molecular sieve with a silicon-aluminum ratio of 300 was used as a raw material to prepare a fractal structure titania photocatalyst.

[0044] Add 10 ml of tetrabutyl titanate into 50 ml of absolute ethanol, and stir evenly to obtain a titanium ion solution. Drop 2 mL of 0.1 mol / L nitric acid solution into 50 mL of deionized water, and stir thoroughly to obtain an electrolyte. Fully mix 10 g of molecular sieves with a silicon-aluminum ratio of 300, an electrolyte solution, and a titanium ion solution to obtain a precursor liquid. Drop 7 mL of 0.1 mol / L nitric acid solution into 60 mL of deionized water, and stir well to obtain a buffer solution.

[0045] Such as figure 2 As shown, two rod-shaped titanium cathodes are symmetrically placed on both sides of the platinum sheet anode to assemble a parallel discharge system. The two rod-shaped titanium cathodes used are both 4 mm in diameter and 20 cm in length. The two rod-shaped cathodes are both inserted into the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com