A kind of electrocatalytic material loaded with vanadium-cobalt alloy nanoparticles and its preparation method

An electrocatalytic material and nanoparticle technology, which can be used in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems of low catalytic activity, poor stability, and low cost. , to achieve the effect of improving catalytic activity, good stability, and efficient hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Take 0.25g of cobalt nitrate and 0.1g of vanadium acetylacetonate and add it to 30g of polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 15wt%, stir evenly by magnetic force, and then use electrospinning method The solution is spun, the spinning voltage is controlled to be 15kV, the distance from the receiving device to the spinning needle is 15cm, and the solution flow rate is 0.01mL / min to obtain a mixed nanofiber membrane;

[0041] (2) Put 0.5g of the prepared mixed nanofiber membrane into a corundum boat, place it in the middle of the tube furnace, first raise the temperature to 230°C at a heating rate of 5°C / min, and keep it warm for 3 hours in an air atmosphere; After the heat preservation is over, in a mixed atmosphere of 150sccm argon and 3sccm ammonia, the temperature is raised to 800°C at a rate of 5°C / min, and the carbonization is carried out at 800°C for 3 hours. That is, the prepared Co 3 V / CNFs catalytic material.

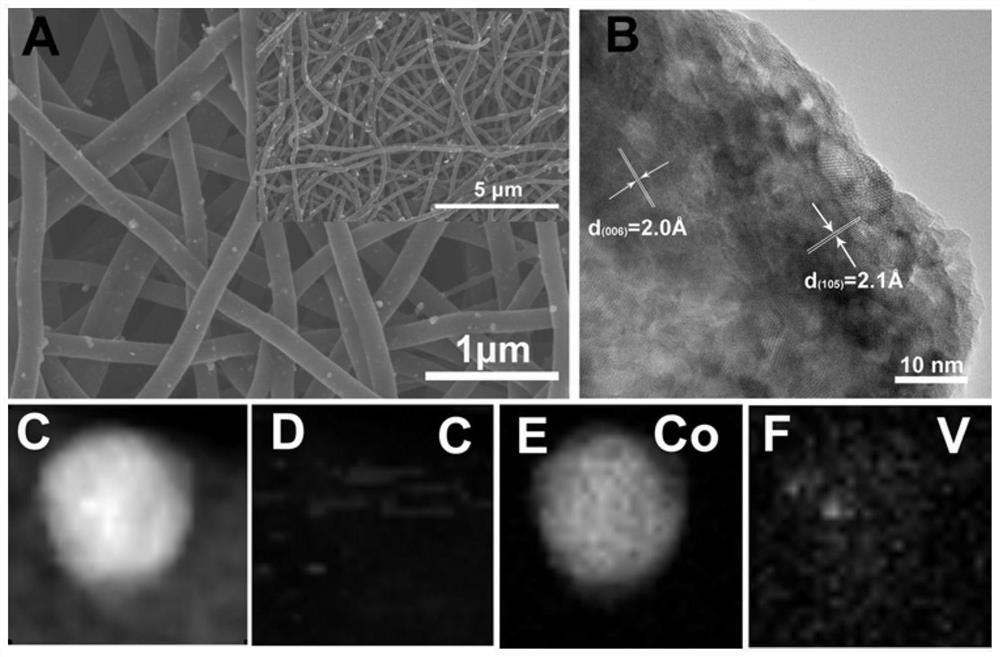

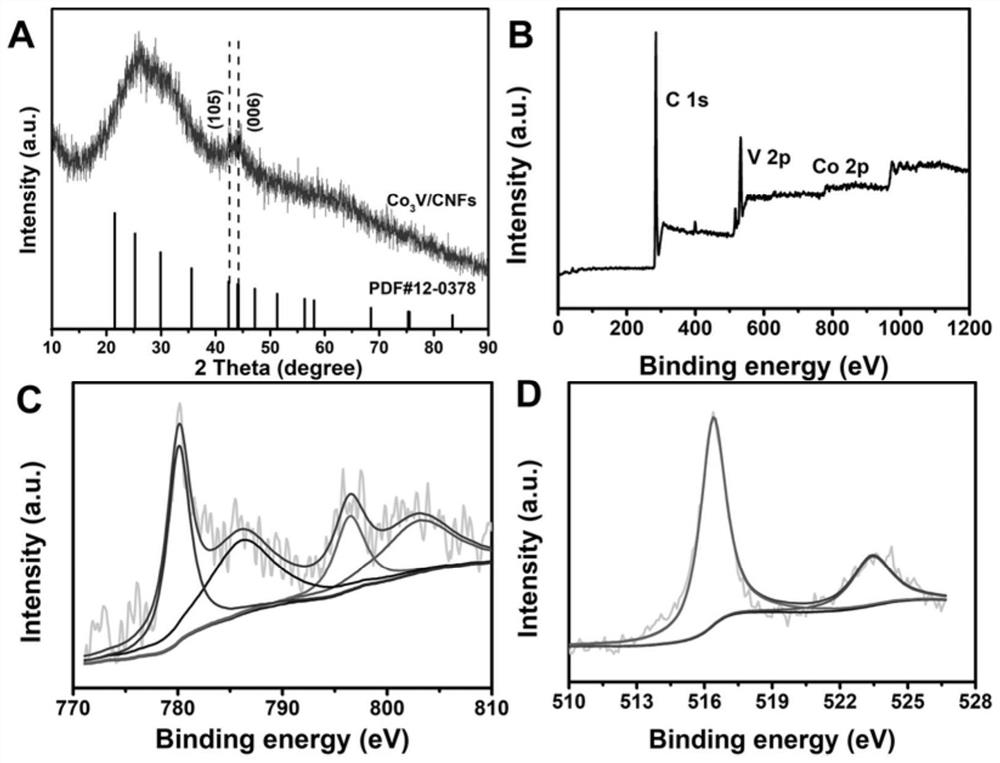

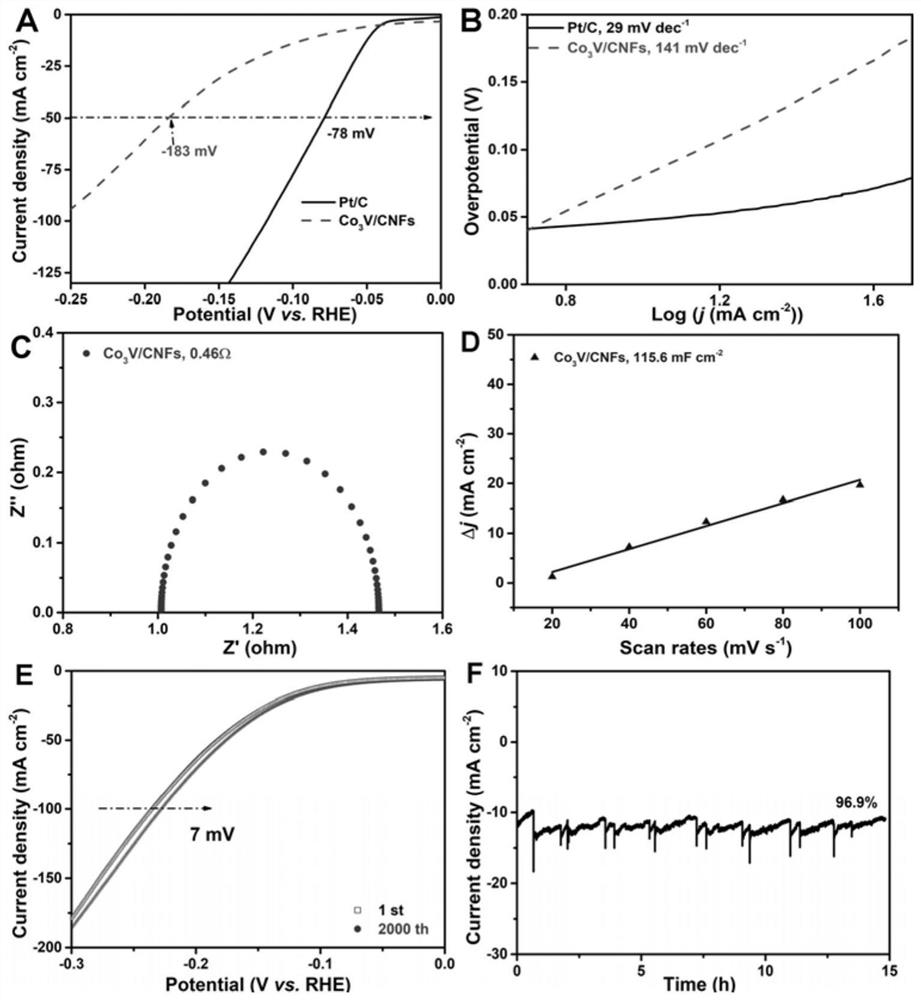

[0042] fig...

Embodiment 2

[0048] (1) Take 0.25g of cobalt nitrate and 0.2g of vanadium acetylacetonate and add it to 30g of polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 8wt%, stir evenly by magnetic force, and then use electrospinning method The solution is spun, the spinning voltage is controlled to be 10kV, the distance from the receiving device to the spinning needle is 10cm, and the solution flow rate is 0.01mL / min to obtain a mixed nanofiber membrane;

[0049] (2) Put 0.5g of the prepared mixed nanofiber membrane into a corundum boat, place it in the middle of the tube furnace, first raise the temperature to 340°C at a heating rate of 5°C / min, and keep it warm for 3 hours in an air atmosphere; After the heat preservation is over, in a mixed atmosphere of 150sccm argon and 2sccm ammonia, the temperature is raised to 900°C at a rate of 5°C / min, and the carbonization is carried out at 900°C for 3 hours. That is, the catalytic material is prepared.

[0050] (3) will Co 3 ...

Embodiment 3

[0052] (1) Add 0.25g of cobalt nitrate and 0.48g of vanadium acetylacetonate to 30g of polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 18wt%, stir evenly by magnetic force, and then use electrospinning method The solution is spun, the spinning voltage is controlled to be 10kV, the distance from the receiving device to the spinning needle is 10cm, and the solution flow rate is 0.01mL / min to obtain a mixed nanofiber membrane;

[0053] (2) Put 0.5g of the prepared mixed nanofiber membrane into a corundum boat, place it in the middle of the tube furnace, first raise the temperature to 230°C at a heating rate of 5°C / min, and keep it warm for 3 hours in an air atmosphere; After the heat preservation is over, in a mixed atmosphere of 200sccm argon and 2sccm ammonia, the temperature is raised to 800°C at a rate of 5°C / min, and the carbonization is carried out at 800°C for 3 hours. That is, the catalytic material is prepared.

[0054] (3) will Co 3 V / CNFs were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com