Palladium-copper supported sub-nanometer catalyst and preparation method thereof

A supported catalyst and catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, hydrogenation hydrocarbon production, etc., can solve the problems of multiple and complex molecules and reactions, and achieve low catalytic cost, high selectivity, and control Effect of Reactor Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of PdCu / Al by Co-impregnation 2 o 3 Catalyst, wherein the Pd content is 0.025%, the Cu content is 0.26%, and the alumina support is γ-Al 2 o 3 , the specific surface area is 160m 2 / g, the specific steps are as follows:

[0053] (a) Calculate the consumption of corresponding precursor copper nitrate and palladium nitrate, and configure solution according to the volume of corresponding solution impregnated with aluminum oxide equivolume;

[0054] (b) Add the solution dropwise evenly on the alumina carrier, so that the carrier is just saturated and absorb the prepared solution; (c) Aging the impregnated carrier at room temperature for 1 hour, and drying at 80° C. overnight;

[0055] (d) Calcining the catalyst obtained in (c) at 450° C. for 3 h.

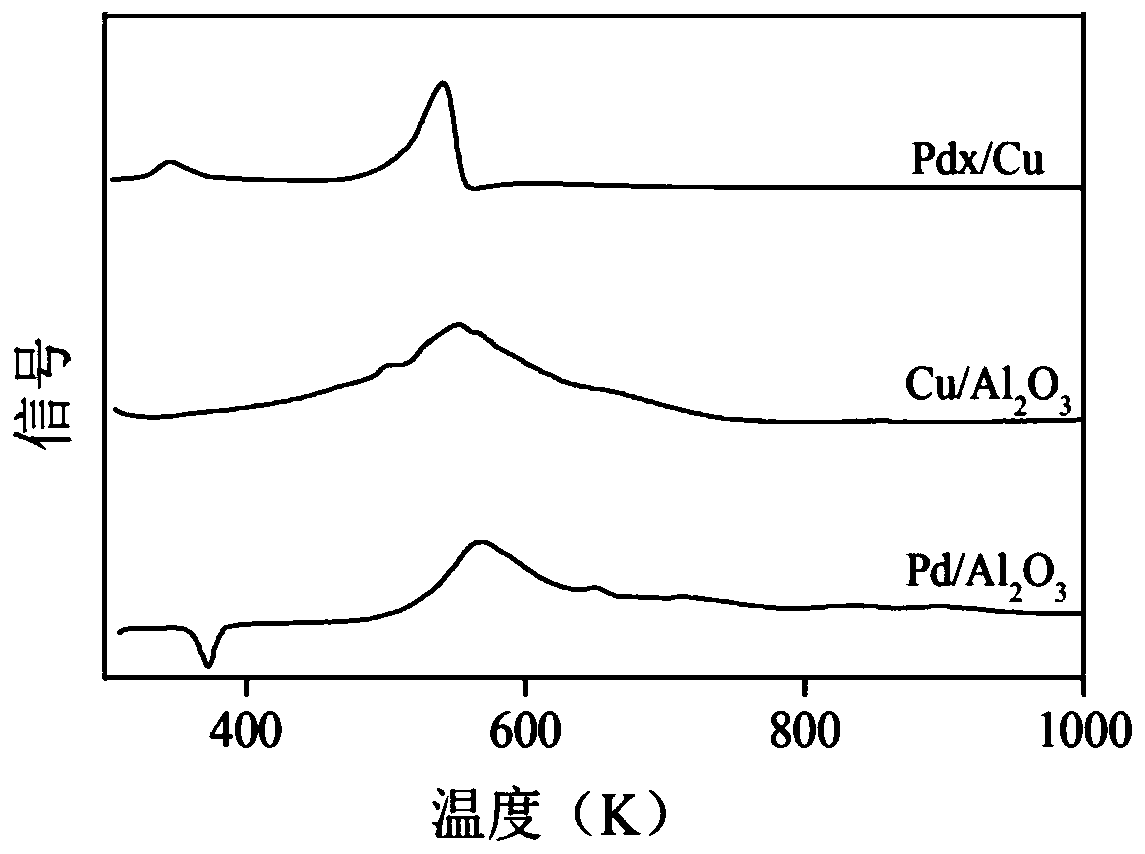

[0056] Perform TPR characterization of the obtained catalyst to obtain its surface oxide state, such as figure 1 As shown, among them, Pd, Cu monometallic catalysts were also characterized by TPR as reference ma...

Embodiment 2

[0060] Preparation of PdCu / SiO by Step-wise Impregnation Method 2 Catalyst, the specific surface area of silica is 230m 2 / g, Pd content 0.06%, Cu content 0.5%, concrete steps are as follows:

[0061] (a) Calculate the amount of precursor cupric chloride and palladium chloride according to the load data, and prepare the solution according to the volume corresponding to the equal volume impregnation of silicon oxide;

[0062] (b) the cupric chloride solution is evenly added dropwise on the catalyst carrier, so that the carrier is just saturated and adsorbed with the prepared solution;

[0063] (c) Aging for 1 hour and drying at 100°C for 5 hours;

[0064] (d) calcining at 500°C for 3h;

[0065] (e) palladium chloride solution is evenly added dropwise on the catalyst carrier, so that the carrier is just saturated and adsorbed with the prepared solution;

[0066] (f) Aging for 3h, drying at 80°C for 8h;

[0067] (g) Calcination at 400°C for 3h.

[0068] After reducing the...

Embodiment 3

[0071] Preparation of PdCu / SiO by Galvanic displacement method 2 Catalyst, wherein Pd content 0.12%, Cu content 0.8%, concrete steps are as follows:

[0072] (a) calculate the consumption of precursor copper nitrate and palladium nitrate according to load data;

[0073] (b) impregnating copper nitrate equal volumes on the silicon oxide carrier, the specific steps are the same as (b)-(d) in Example 2;

[0074] (c) reducing the catalyst obtained in (b) at 250° C. for 1 h;

[0075] (d) carrying out the metal replacement reaction of the catalyst obtained in (c) in an ultrasonic reactor, and the replacement metal solution is a palladium nitrate solution;

[0076] (e) Vacuum drying at room temperature for 24 h.

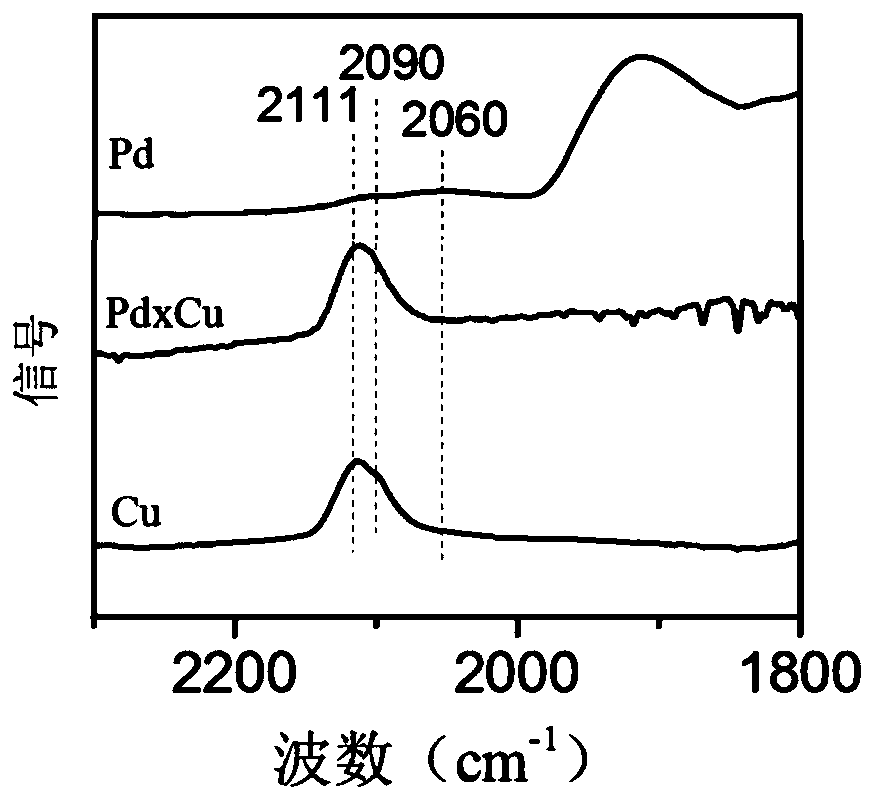

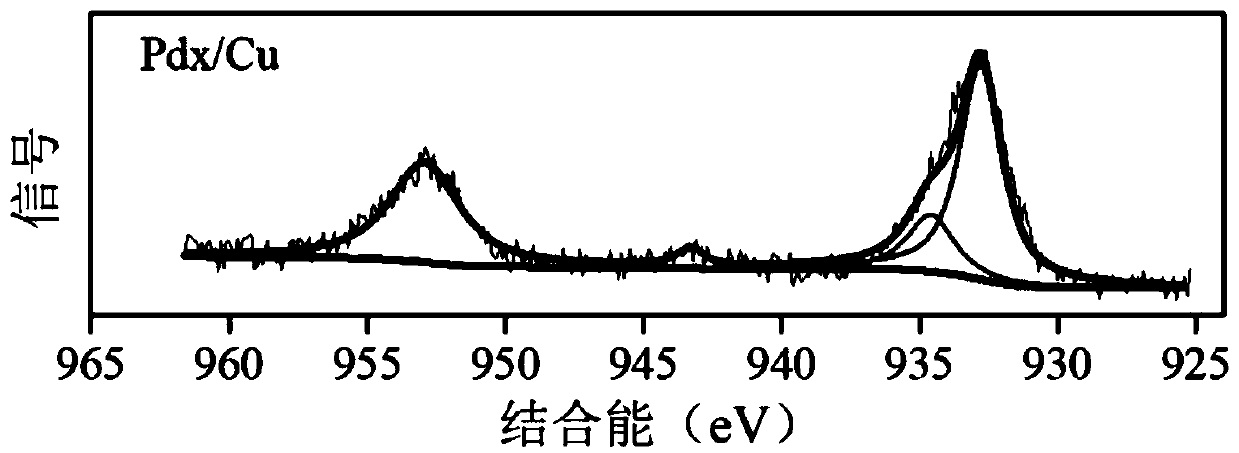

[0077] The catalyst was characterized by CO-infrared adsorption, and similar figure 2 In the spectra, the bulk phase adsorption peak of Pd disappears, which proves the existence of subnanometer Pd. The catalyst was characterized by EXAFS, and data fitting was carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com