Method for efficiently producing steroid medicine precursor by fermentation

A technology of precursors and steroids, applied in the field of biocatalysis, can solve problems such as low production efficiency, reduced production cost, and long fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

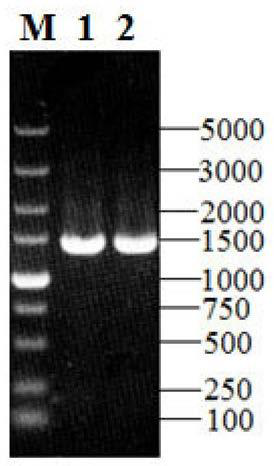

[0026] Example 1 Acquisition of type II NADH dehydrogenase gene (ndh)

[0027] The bacterial strain (hereinafter referred to as MNR) with the preservation number CICC 21097 was inoculated in the basal medium containing phytosterols (glucose 10g / L, MgSO 4 0.5g / L, K 2 HPO 4 0.5g / L, (NH 4 ) 2 HPO 4 3.5g / L, citric acid 2g / L, ferric ammonium citrate 0.05g / L, phytosterol 5g / L) cultivated for 60 hours to obtain samples for transcriptome sequencing. The obtained gene transcript sequences were compared in NCBI's non-redundant protein sequence database and KEGG's protein database to obtain the protein with the highest sequence similarity to each gene transcript sequence. The protein information is the functional annotation information of the protein corresponding to each gene transcript sequence. The gene transcript sequence obtained by searching NADH dehydrogenase from the annotation information is the type Ⅱ NADH dehydrogenase gene. Primers ndh-F and ndh-R were designed usin...

Embodiment 2

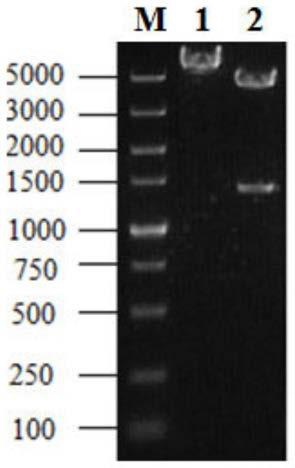

[0031] Example 2 Constructing Genetic Engineering Expression Vectors for Type II NADH Dehydrogenase Gene Overexpression

[0032] Constructing a genetic engineering expression vector for the overexpression of the type II NADH dehydrogenase gene itself, the process includes: recovering the type II NADH dehydrogenase gene obtained in Example 1 through double digestion with BamHI and HindIII, and recovering it with the same The digested pMV261 plasmid was ligated overnight at 16°C under the action of T4 DNA ligase, and the ligated product was transformed into Escherichia coli DH5α by chemical transformation, and positive clones were obtained by kanamycin screening. The plasmids in the positive clones were extracted and verified by enzyme digestion ( figure 2 ) and sequencing, the successfully constructed genetic engineering expression vector pMV261-ndh for type II NADH dehydrogenase gene self-overexpression.

Embodiment 3

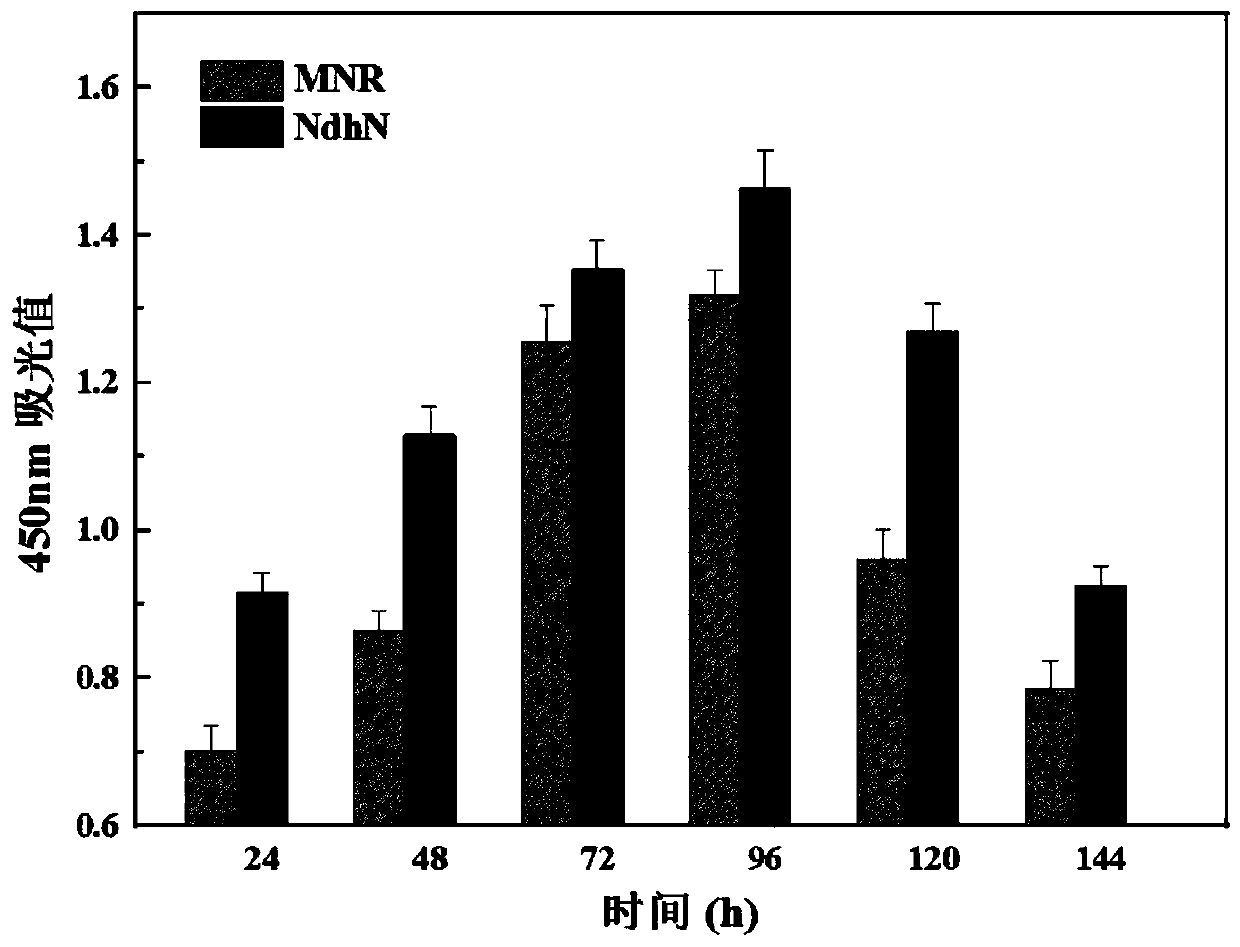

[0033] Example 3 Construction of type II NADH dehydrogenase gene self-overexpression strain NdhN

[0034] Preparation of mycobacterial MNR competent cells: Inoculate MNR strains into LB medium and culture at 30°C until OD 600 1.0, according to 10% inoculum amount transferred to the seed medium for secondary seed culture; 24h after adding 2% glycine to continue culturing for 24h. Collect the bacteria by centrifugation, wash the suspended bacteria with 10% pre-cooled glycerin of 1 times, 3 / 4 times, 1 / 2 times and 1 / 4 times the volume of fermentation broth respectively and centrifuge, finally add 1 / 25 times of 10% glycerol Suspend the bacteria and store in sub-packages;

[0035] Electroporation: Take 10 μL of the pMV261-ndh genetic engineering expression vector obtained in Example 2, add it to 100 μL of competent bacteria and let it stand for 30 minutes, then transfer to the electroporation cuvette for clicking. Electroporation conditions were 2kV / cm, 25μF, 720Ω for 3-6ms, place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com