Polyacrylonitrile fiber containing hyperbranched polymer and its preparation method

A hyperbranched polymer and polyacrylonitrile fiber technology, which is applied in the field of fiber modification, can solve the problems of difficult nanoscale dispersion and poor processing performance of hyperbranched polymers, and achieve improved thermal stability, good processing performance, and improved processing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

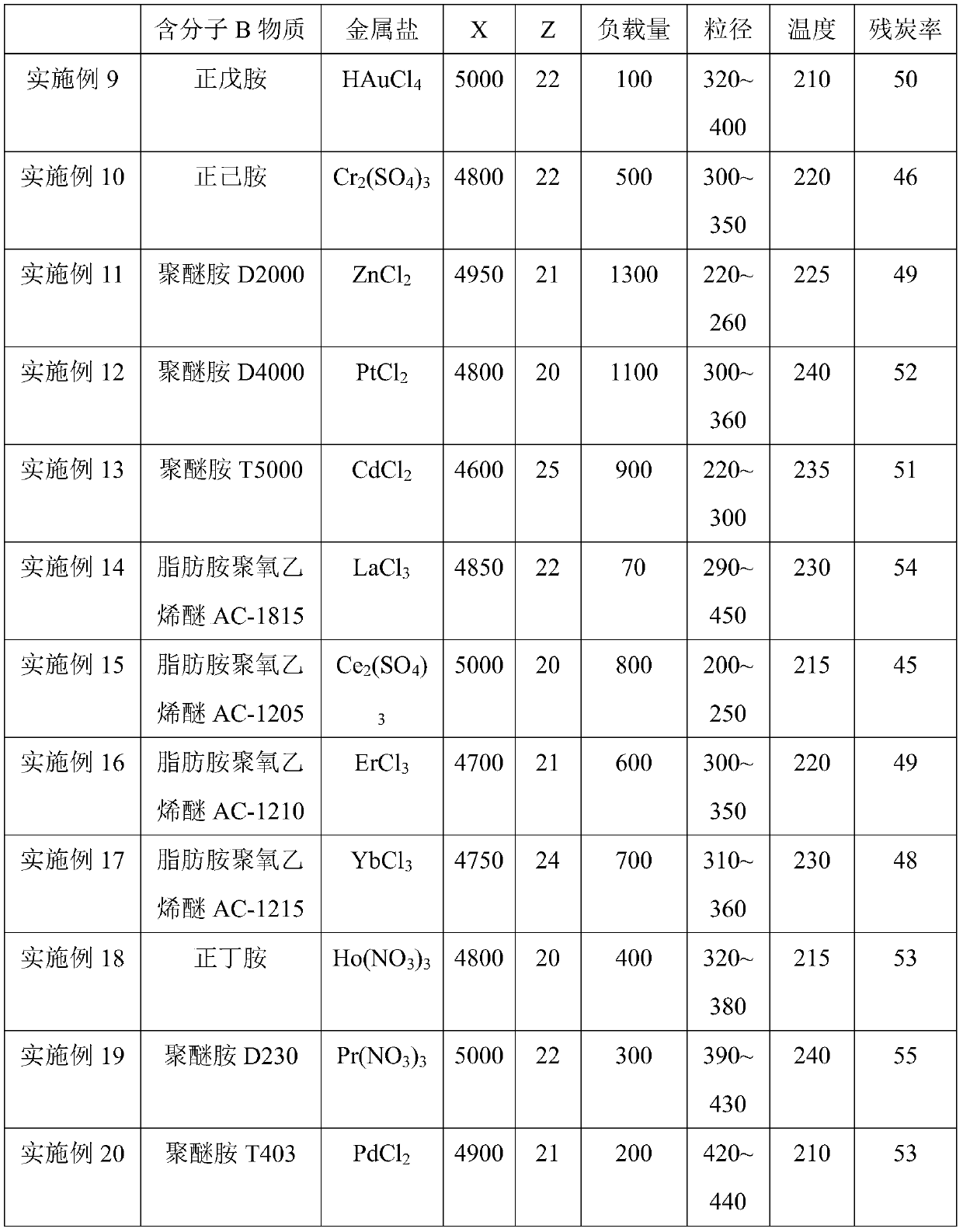

Embodiment 1

[0069] The preparation method of the polyacrylonitrile fiber containing hyperbranched polymer, concrete steps are as follows:

[0070] (1) Preparation of a substance containing molecule A;

[0071] Pyrazine-2,3-dicarboxylic acid and 1,1,1-tri(hydroxymethyl)propane with a molar ratio of 1:1 were subjected to an esterification reaction at a temperature of 150°C under nitrogen protection for 1 h, and then at temperature Under the conditions of 200°C and 0 MPa, vacuumize the polycondensation reaction for 4 hours to obtain the substance containing molecule A, wherein stirring is required during the esterification reaction and polycondensation reaction, and the stirring rate is 200rpm;

[0072] (2) The substance containing molecule A prepared in step (1) is mixed with an aqueous solution of n-propylamine (containing substance B containing molecule) at a concentration of 0.3mol / L in the form of powder, accompanied by stirring during mixing, and then poured into the mixing system AgN...

Embodiment 2

[0079] The preparation method of the polyacrylonitrile fiber containing hyperbranched polymer, concrete steps are as follows:

[0080] (1) Preparation of a substance containing molecule A;

[0081] 2-carboxyethylphenylphosphinic acid and tris(2-hydroxyethyl)isocyanurate with a molar ratio of 1:2 were subjected to esterification reaction at a temperature of 180°C under nitrogen protection for 2h, and then at temperature The temperature is 180°C, and the pressure is -0.1MPa, and the polycondensation reaction is carried out for 3 hours to obtain the substance containing molecule A. Stirring is required during the esterification reaction and polycondensation reaction, and the stirring rate is 300rpm;

[0082] (2) The substance containing molecule A obtained in step (1) is mixed with an aqueous solution of n-butylamine (containing substance B containing molecule) at a concentration of 0.58mol / L in the form of powder, accompanied by stirring during mixing, and then mixed FeCl with ...

Embodiment 3

[0089] The preparation method of the polyacrylonitrile fiber containing hyperbranched polymer, concrete steps are as follows:

[0090] (1) Preparation of a substance containing molecule A;

[0091] 5-tert-butyl-1,3-benzenedicarboxylic acid and 2,4,5-trihydroxybutyrophenone at a molar ratio of 1:3 were subjected to an esterification reaction at a temperature of 160°C under nitrogen protection for 1.5 hours, Then vacuumize the polycondensation reaction at a temperature of 190°C and a pressure of -0.05MPa for 2 hours to obtain a substance containing molecule A, wherein stirring is required during the esterification reaction and polycondensation reaction, and the stirring rate is 400rpm;

[0092] (2) Mix the substance containing molecule A prepared in step (1) in the form of powder with an aqueous solution of polyetheramine D230 (containing substance B containing molecule) at a concentration of 0.49mol / L, and stir when mixing, and then add FeCl with a concentration of 0.8mol / L wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com