A fabrication method for multiple epitaxial superjunction devices with improved reverse recovery characteristics

A technology of super junction devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high production cost, large terminal area, etc., and achieve the effect of increasing reverse recovery softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Taking an N-type planar gate super-junction MOSFET device as an example, the first conductivity type is N-type, the second conductivity type is P-type, a method for manufacturing a super-junction device with multiple epitaxy, on a top view plane , the semiconductor device includes an active region and a terminal region surrounding the active region;

[0039] The active region includes several superjunction device units connected in parallel, and the manufacturing method of the superjunction device unit includes the following steps:

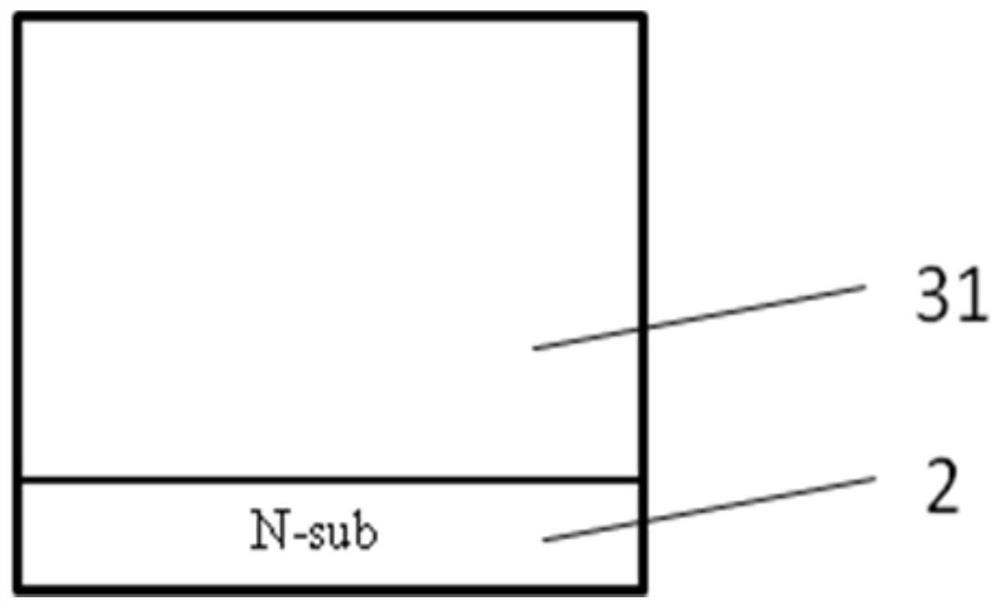

[0040] like figure 1 As shown, the first step: select an N-type silicon substrate as the N-type substrate 2, and grow a first N-type epitaxial layer 31 on the upper surface of the N-type substrate 2 by using an epitaxial process;

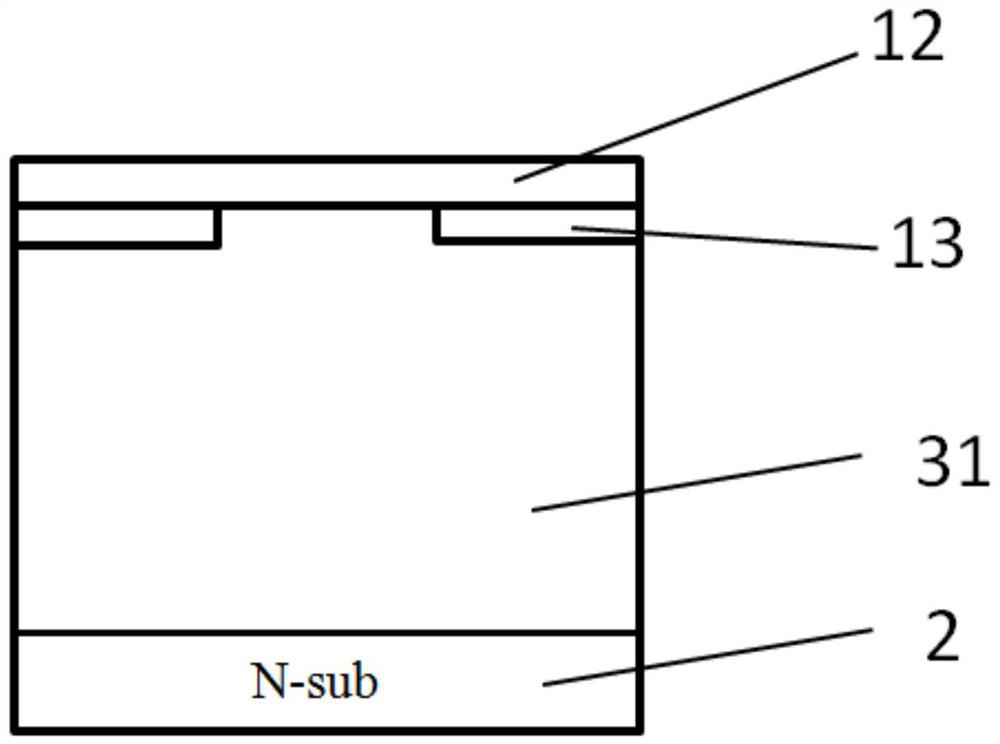

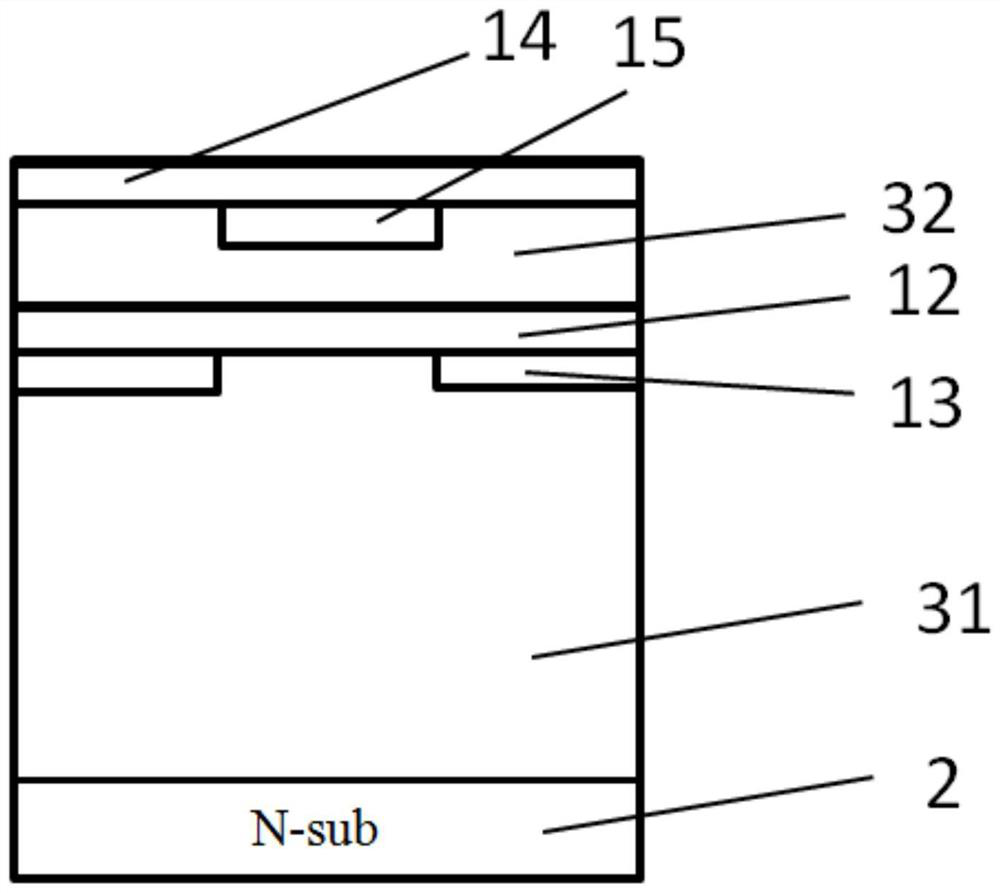

[0041] like figure 2 As shown, the second step: generally implant N-type impurities on the surface of the first N-type epitaxial layer 31 to form an undiffused N-type layer 12, and then selective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com