Ion implantation or implantation and deposition system

A deposition system and ion implantation technology, applied in the field of ion implantation or implantation and deposition systems, can solve the problems of limiting the application of ion implantation technology, unsatisfactory particle implantation quality, uneven implantation dose, etc., and achieve low cost, simple method, and isolation The effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

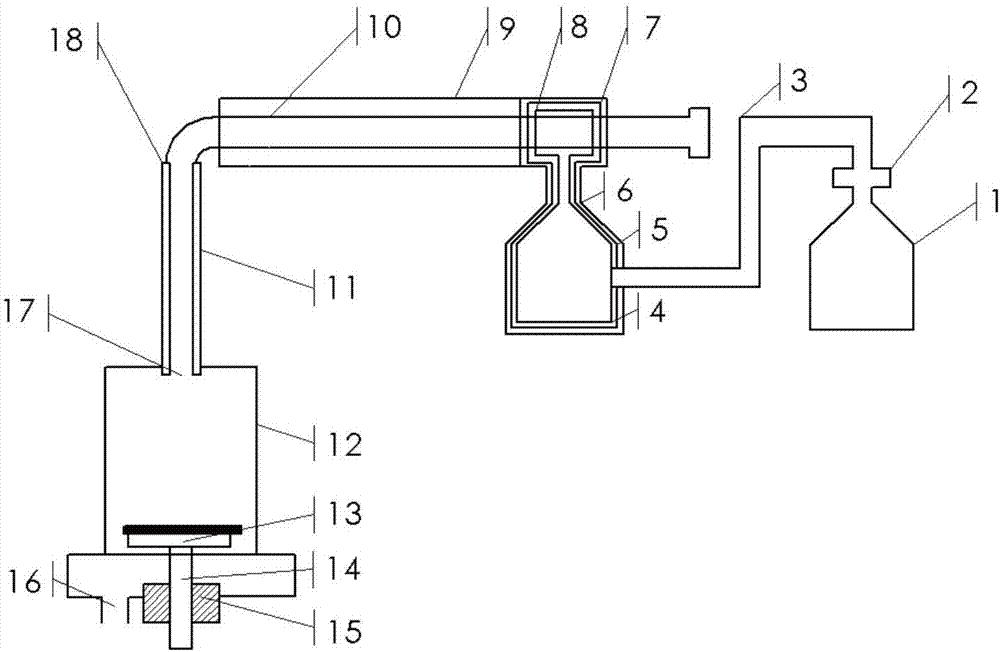

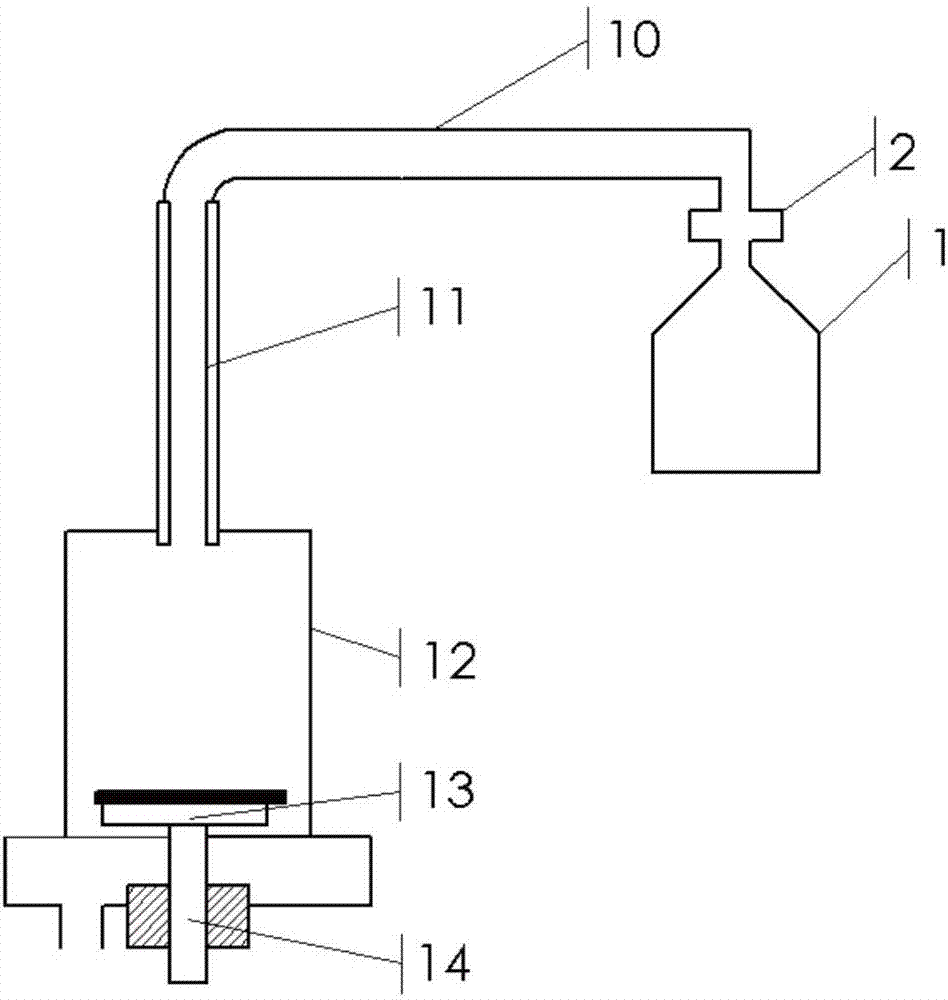

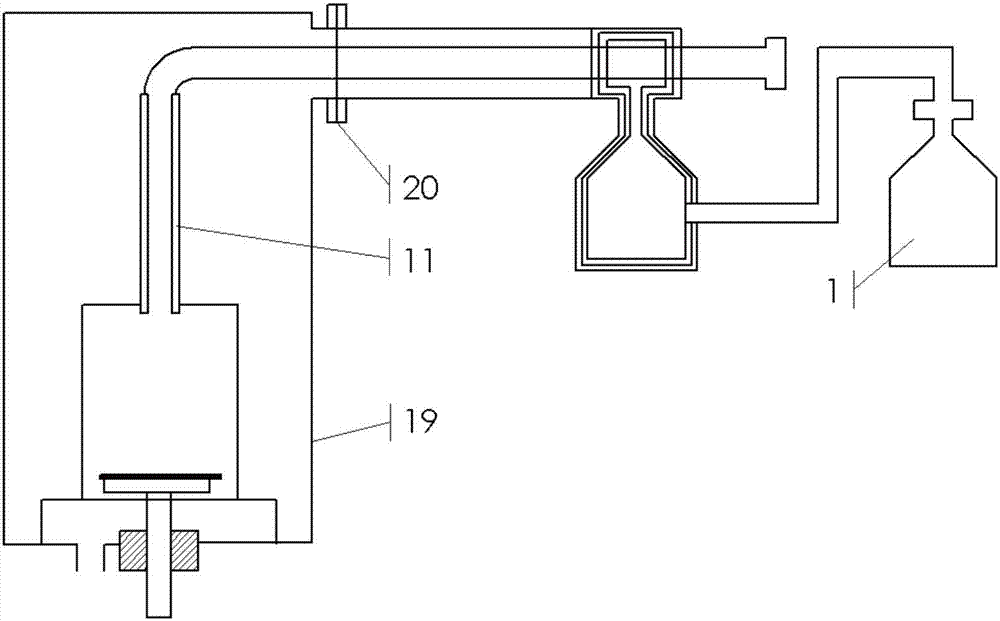

[0056] Example 1: In this embodiment, the aluminum oxide ceramic straight tube and the quartz glass straight tube with an inner diameter of 4 mm and a length of 200 mm are respectively selected as plasma-enhanced discharge devices, and hydrogen ions are implanted into the surface of single crystal silicon. Figure 4 device in .

[0057] Specific steps are as follows:

[0058] Step (1): An alumina ceramic straight tube and a quartz glass straight tube are respectively selected as plasma-enhanced discharge devices to build an ion implantation or implantation and deposition system. One end of the plasma-enhanced discharge device 11 is connected to the injection or injection and deposition studio 12 of the center opening of the end face. The injection or injection and deposition studio 12 is placed on the cathode target table 13. The mechanical pump and the molecular pump make the studio 12 When the vacuum state is reached, the gas is discharged through the exhaust port 16 of the...

example 2

[0066] Example 2: In this embodiment, an alumina ceramic straight tube and a quartz glass straight tube with an inner diameter of 4mm and a length of 200mm are respectively selected as the plasma enhanced discharge device, and oxygen ions are implanted on the surface of the single crystal silicon, and the Figure 4 device in . The difference between this embodiment and the first embodiment is: the oxygen flow rate is 10-60 sccm, and the oxygen ion implantation to the surface of the single crystal silicon is completed. Other steps are the same as Example 1.

[0067] The result is as Image 6 As shown, the average current in the figure is the injection current of oxygen ions. The more oxygen ions are injected, the greater the current, so the magnitude of the current can represent the ionization rate of particles.

[0068] Depend on Image 6 It can be seen that the current of oxygen ions can be increased by using a plasma-enhanced discharge device under the same gas flow rate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com